Oct . 05, 2024 00:05 Back to list

Comparing Wholesale PPR Pipe and PVC Pipe for Your Construction Needs

Comparing Wholesale PPR Pipe and PVC Pipe An In-Depth Look

When it comes to plumbing and piping solutions, two popular materials often come to the forefront PPR (Polypropylene Random Copolymer) and PVC (Polyvinyl Chloride). Both materials have unique properties and advantages that cater to various applications in residential, commercial, and industrial settings. This article explores the key differences between wholesale PPR pipe and PVC pipe, helping consumers and professionals make informed decisions.

Material Composition and Properties

PPR pipes are made from a type of polypropylene that offers excellent resistance to high temperatures and pressures. This makes PPR pipes particularly suitable for hot water systems and applications where temperature stability is essential. On the other hand, PVC pipes are constructed from a plastic polymer widely recognized for its durability and versatility. PVC pipes are lightweight, corrosion-resistant, and have a smooth interior surface, which reduces friction and improves flow efficiency.

Temperature and Pressure Resistance

One of the standout features of PPR pipe is its capacity to handle high temperatures. It can typically withstand temperatures up to 95 degrees Celsius (203 degrees Fahrenheit), making it a preferred choice for hot water plumbing. In contrast, while PVC pipes are suitable for cold water applications and can handle temperatures up to 60 degrees Celsius (140 degrees Fahrenheit), they are not recommended for hot water systems. Therefore, if a project involves hot water transport, PPR is often the superior choice.

Cost and Availability

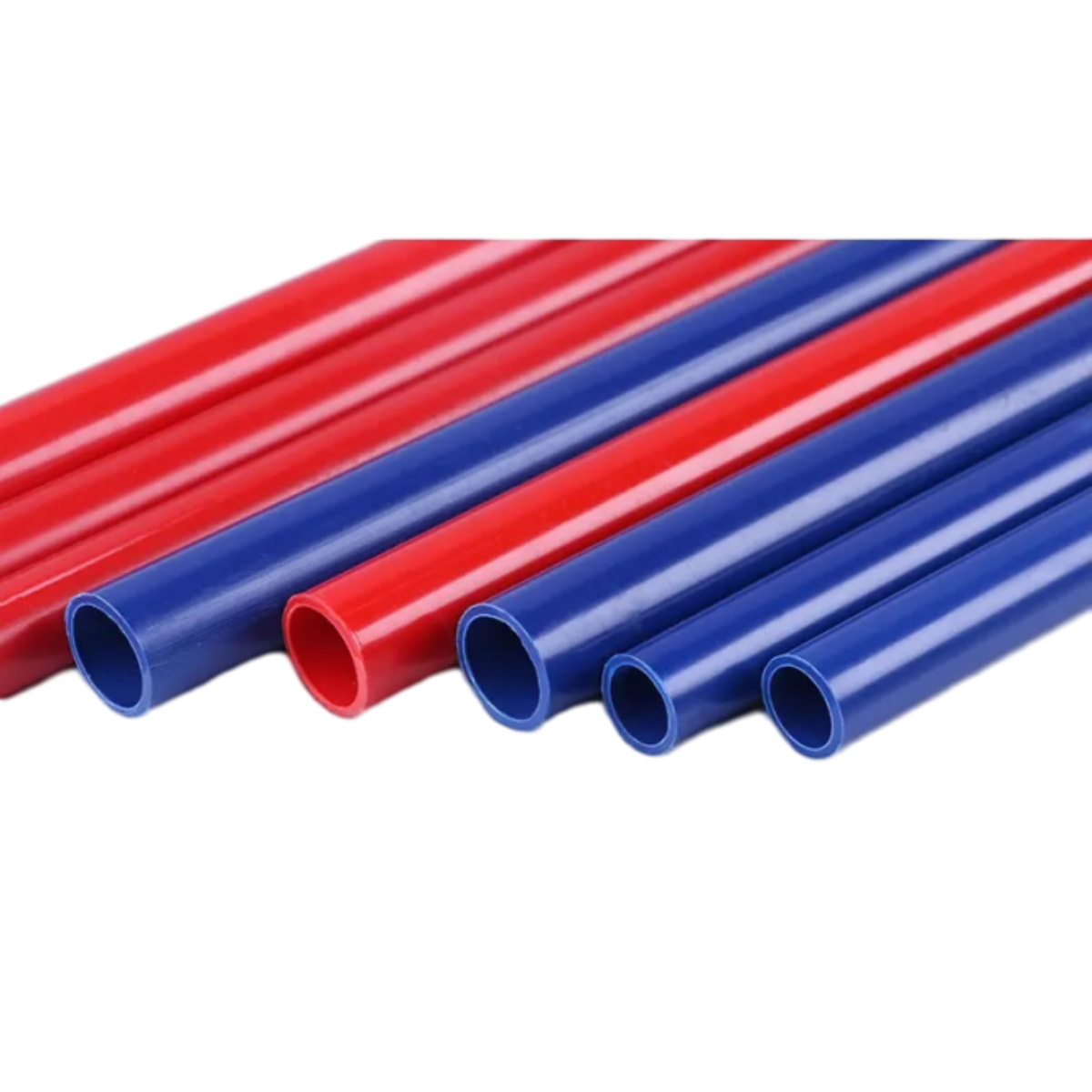

wholesale ppr pipe vs pvc pipe

When considering wholesale options, the cost of PPR and PVC pipes can vary significantly. Generally, PVC pipes are less expensive than PPR pipes due to the lower production costs and widespread availability. This makes PVC a popular choice for budget-conscious projects. However, the initial investment in PPR pipes might pay off in the long run due to their durability, lifespan, and lower maintenance requirements, especially in high-temperature applications.

Installation

Both PPR and PVC pipes offer relatively easy installation processes. PVC pipes are commonly joined using solvent cement, which creates a strong, permanent bond. PPR pipes utilize a fusion welding technique that heats the pipe ends before they are joined. This results in a leak-proof connection, albeit requiring specialized equipment and training for installation. The choice between the two may depend on available resources and the specific requirements of the project.

Environmental Considerations

Environmentally, both materials raise different concerns. PVC production involves the use of chlorine, which can pose environmental challenges, and the disposal of PVC products can lead to pollution. PPR, being a more stable polymer, tends to have a smaller environmental footprint when it comes to both the manufacturing process and end-of-life disposal.

Conclusion

In summary, the choice between wholesale PPR pipes and PVC pipes hinges on several factors, including application requirements, budget, and long-term goals. PPR pipe excels in high-temperature applications and offers superior durability, making it a viable choice for demanding environments. Conversely, PVC pipe is affordable and versatile, ideally suited for cold water systems and less demanding applications. Ultimately, understanding the specific needs of a project is key to making the right choice in piping materials.

-

32mm HDPE Pipes Coil: Durable & Flexible Water Supply

NewsAug.05,2025

-

DN100 PVC Well Casing Pipes | Durable Corrosion-Proof

NewsAug.04,2025

-

HORON 25mm PPR Plumbing Pipes - AI-Enhanced & Reliable

NewsAug.03,2025

-

HORON 25mm PPR Pipes - AI-Optimized Plumbing Excellence

NewsAug.02,2025

-

Premier HDPE Sprinkler Pipe Manufacturers | Durable Solutions

NewsAug.01,2025

-

DN500 HDPE Double Wall Corrugated Drain Pipes | Durable & Efficient

NewsJul.31,2025