Aug . 02, 2025 06:20 Back to list

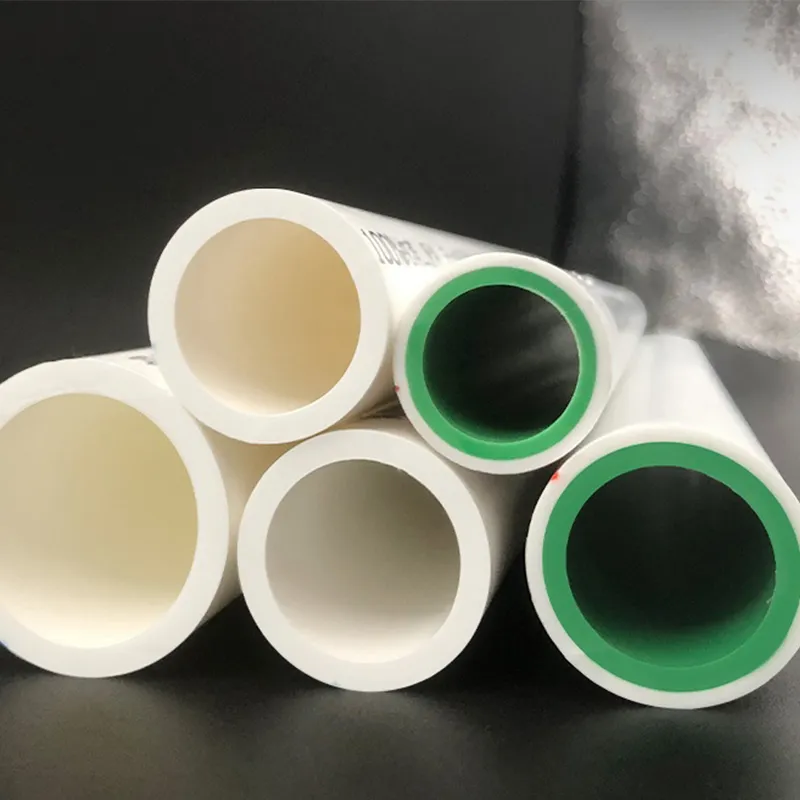

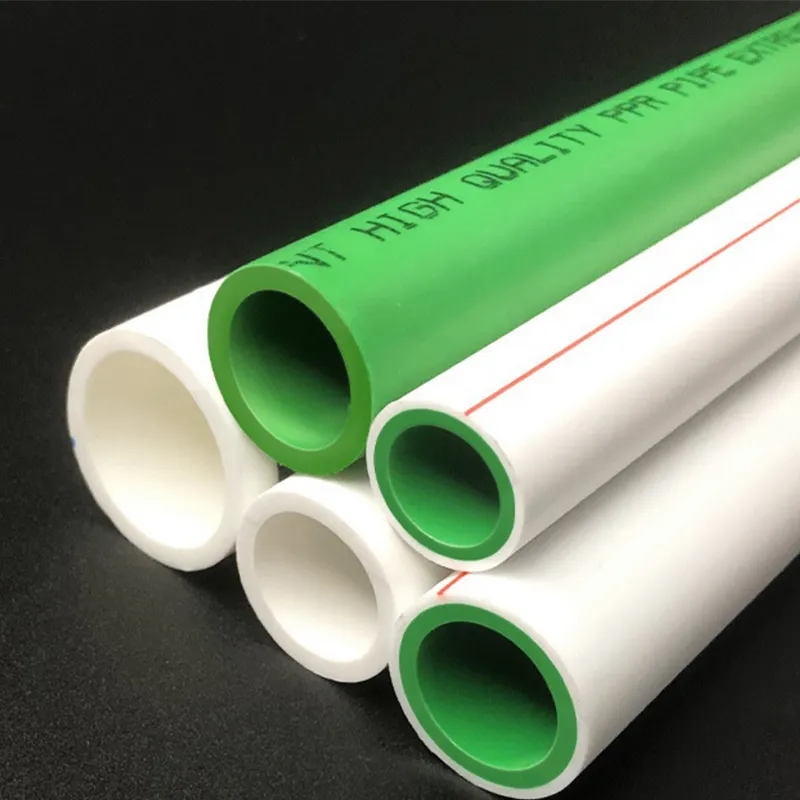

HORON 25mm PPR Pipes - AI-Optimized Plumbing Excellence

Industry Trends: The Rise of Advanced PPR Pipe Systems

Recent years have witnessed a major shift from traditional metal and PVC pipes to more advanced polymer-based systems in plumbing and fluid transmission. According to Statista (2023), the global PPR pipe market size is projected to reach USD 9.1 billion by 2028, growing at a CAGR of 4.6% from 2022 to 2028. HORON 25mm PPR Plumbing Pipes exemplify this shift with their blend of technical precision, compliance with ISO/EN standards, and outstanding longevity.

Technical Parameters: HORON 25mm PPR Plumbing Pipes Specifications

| Model | Diameter (mm) | Wall Thickness (mm) | Material Grade | Pressure Rating (PN) | Length per Piece (m) | Certifications |

|---|---|---|---|---|---|---|

| HORON PPR-25 | 25 | 3.5 - 4.2 | PPR Type 3 (Random Copolymer Polypropylene) | PN 10 / PN 16 / PN 20 | 4, 5.8, 6 | ISO 15874, EN ISO 15874, CE |

- Melting Point: 130-150°C

- Thermal Conductivity: 0.24 W/mK

- Hydraulic Resistance: Smooth inner surface ensures low pressure drop

- Life Expectancy: ≥ 50 years (at 20°C and design pressure)

- Chemical Resistance: High resistance to acids, bases, salts, chlorides, disinfectants

Manufacturing Process: How HORON 25mm PPR Plumbing Pipes Are Made

- Material: Premium Raw PPR Type 3 Resin (Food Grade) – free from heavy metals & toxins as required by FDA and EU.

- Extrusion: Advanced twin-screw extruders ensure consistent wall thickness, smoothness, and molecular orientation.

- Calibration & Cooling: Pipe shape and dimensional accuracy set in multi-chamber vacuum and water cooling baths.

- CNC Cutting: Each pipe is cut to length with tolerance ≤0.3% using German CNC saw.

- Testing & Quality Control: 100% hydrostatic pressure test (over 2× nominal), random destructive burst test, ultrasonic thickness test; documentation per ISO 15874.

- Final Inspection: Appearance, marking and batch record for traceability.

Technical Advantages of HORON 25mm PPR Plumbing Pipes

- Sustainability: 100% recyclable and energy-saving during operation; PPR's low thermal conductivity leads to up to 35% energy saving compared to steel pipes in hot water systems (source: Sciencedirect, 2023).

- Durability: Withstands over 10,000 cycles of pressure from 0-16 bar without fatigue.

- Corrosion Resistance: No risk of scaling, rust or chemical attack unlike galvanized steel or copper.

- Hygienic Safety: Food-grade polymer meets ISO 15874, DIN 8077/8078, FDA drinking water requirements.

- Easy Installation: Lightweight, fusion-welded joints eliminate risk of leakage (fusion joint > parent pipe strength).

- Long Lifespan: 50 years+ at 20°C & design pressure proven by accelerated aging tests (EN ISO 9080).

- Thermal Expansion: Low coefficient of expansion (α = 0.15 mm/m·K); allows for cost-effective support structures.

- Excellent Insulation: Maintain water quality, prevent heat loss or condensation on walls.

HORON vs. Leading PPR Pipe Brands: Competitive Comparison

| Brand | Material Purity | Wall Thickness Consistency | Lifetime @ 20°C/PN16 | Certification | Global Projects |

|---|---|---|---|---|---|

| HORON 25mm PPR | 100% Virgin PPR-3 | <2% Tolerance | ≥ 50 years | ISO, CE, EN | >1800 sites (global) |

| Aquatherm | 99.8% PPR-3 | <3% Tolerance | ≥ 50 years | ISO, DVGW | Global |

| Bänninger | 99% PPR-3 | <5% Tolerance | ~47 years | ISO, EU | Europe, Asia |

| Local Brand X | 95-98% | <7% | 20-30 years | Partial | Regional |

HORON 25mm PPR Plumbing Pipes stand out not just for their purity and consistent geometry, but also for adherence to the strictest international standards and proven global deployments in over 40 countries.

Customized Solutions: Tailoring HORON 25mm PPR Plumbing Pipes to Your Project

- Custom Lengths/Colors: Precise production per project drawings, corporate branding or coding standards.

- Brass/Metal Embedded Fittings: For demanding industrial/chemical or high-temperature installations.

- Pre-fabrication: Factory-welded ready-to-install modules, reducing onsite labor cost by up to 30%.

- Special PN Ratings: Extra pressure resistance for mining, process industry, or special climate projects.

- Engineering Support: Free BIM models, pressure/flow calculation, and technical selection with 24/7 support for global clients.

HORON 25mm PPR Plumbing Pipes Application Scenarios & Project Cases

- Residential Buildings: Hot/cold potable water supply, radiant floor heating, bathroom renovations.

- Commercial Complexes: Hotels, hospitals, office towers (reliable no-rust piping for hygienic drinking water).

- Industrial Plants: Chemical, food, metallurgy, and pharmaceutical industries (superior acid/base resistance).

- Municipal & Infrastructure: Urban water mains, high-rise booster systems, swimming pools, geothermal loops.

- Green Energy: Solar water heating, heat pump circuits – PPR's thermal stability ensures system longevity and efficiency.

Large-scale installation projects in the Middle East and Asia have also demonstrated the reliability and cost benefits of HORON 25mm PPR Plumbing Pipes in extreme climates, especially compared to steel/PEX alternatives.

Certifications, Industry Partnerships & Authority

- Certifications: ISO 15874, EN 12201, CE, FDA, WRAS, RoHS.

- Testing: Third-party labs: SGS, TÜV Rheinland (reaction to disinfectants, long-term pressure).

- Industry Engagement: Member of International Association of Plumbing & Mechanical Officials (IAPMO).

- Service Experience: Over 20 years in global piping solutions, over 1000+ public and private partnerships.

- References: Used by Fortune 500 clients, leading universities, energy majors.

FAQ: Technical Questions about HORON 25mm PPR Plumbing Pipes

Order, Delivery, Support: Timeline, Guarantee, Service

- Production Lead Time: Typically 7–14 days for standard sizes; 15–22 days for custom projects.

- Packaging: Fully plastic wrapped, end-protected, palletized, ready for international logistics.

- Warranty: 10–25 year product guarantee depending on application & local conditions.

- Technical Support: 24/7 hotline, instant video guidance, and site training during installation or system commissioning.

- Documentation: Full technical documentation and compliance certificates shipped with every order.

Choose HORON 25mm PPR Plumbing Pipes for a no-compromise, future-proof piping solution with world-class industry support and proven project references.

Conclusion & Industry References

In the rapidly evolving piping industry, HORON 25mm PPR Plumbing Pipes deliver a powerful combination of proven engineering, rigorous quality, and compliant safety for the world's most demanding water and fluid systems. Their superiority is evidenced by third-party data, international certifications, and global client satisfaction across a spectrum of sectors.

To deepen your technical knowledge or learn more about advanced PPR pipe deployments, refer to the following industry publications:

- Performance of PPR Pipes in Drinking Water Systems – ResearchGate, 2023

- Recent Advances in Polypropylene Piping – ScienceDirect, 2023

- Pipe Material Selection for Buildings – Eng-Tips Forum

- ISO 15874:2013 – Plastics piping systems for hot and cold water installations

For detailed project consultation, specification advice, or to request data sheets, please contact HORON through their official product page at HORON 25mm PPR Plumbing Pipes.

-

Premier HDPE Sprinkler Pipe Manufacturers | Durable Solutions

NewsAug.01,2025

-

DN500 HDPE Double Wall Corrugated Drain Pipes | Durable & Efficient

NewsJul.31,2025

-

1/2' PVC Electric Protective Pipe - Durable, Lightweight Conduit

NewsJul.31,2025

-

DN25 PPR Water Pipes for Kitchen - Durable & Leak-Proof Plumbing Solution

NewsJul.30,2025

-

HDPE Sprinkler Pipe Manufacturers – Durable Irrigation Solutions

NewsJul.30,2025