Jul . 31, 2025 04:00 Back to list

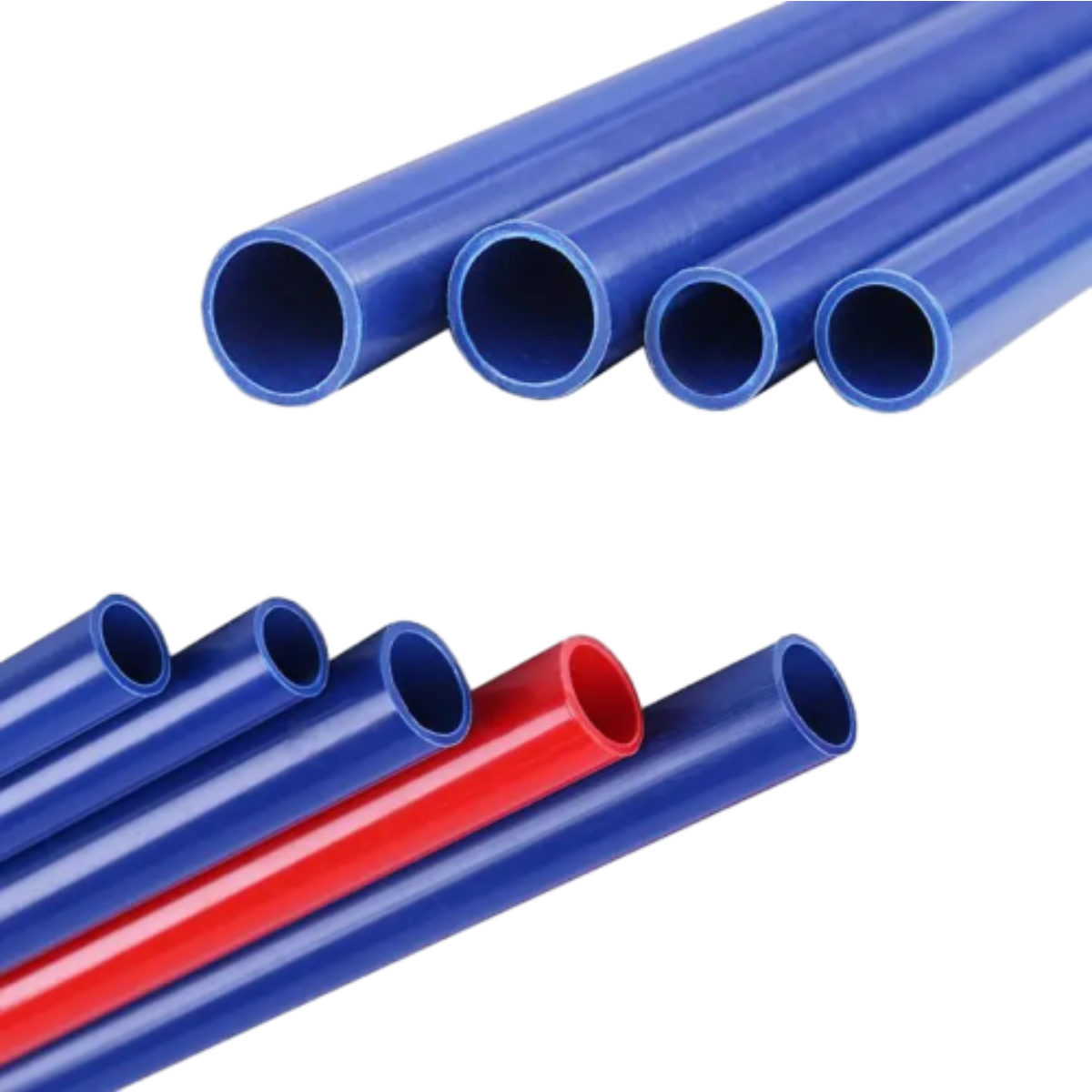

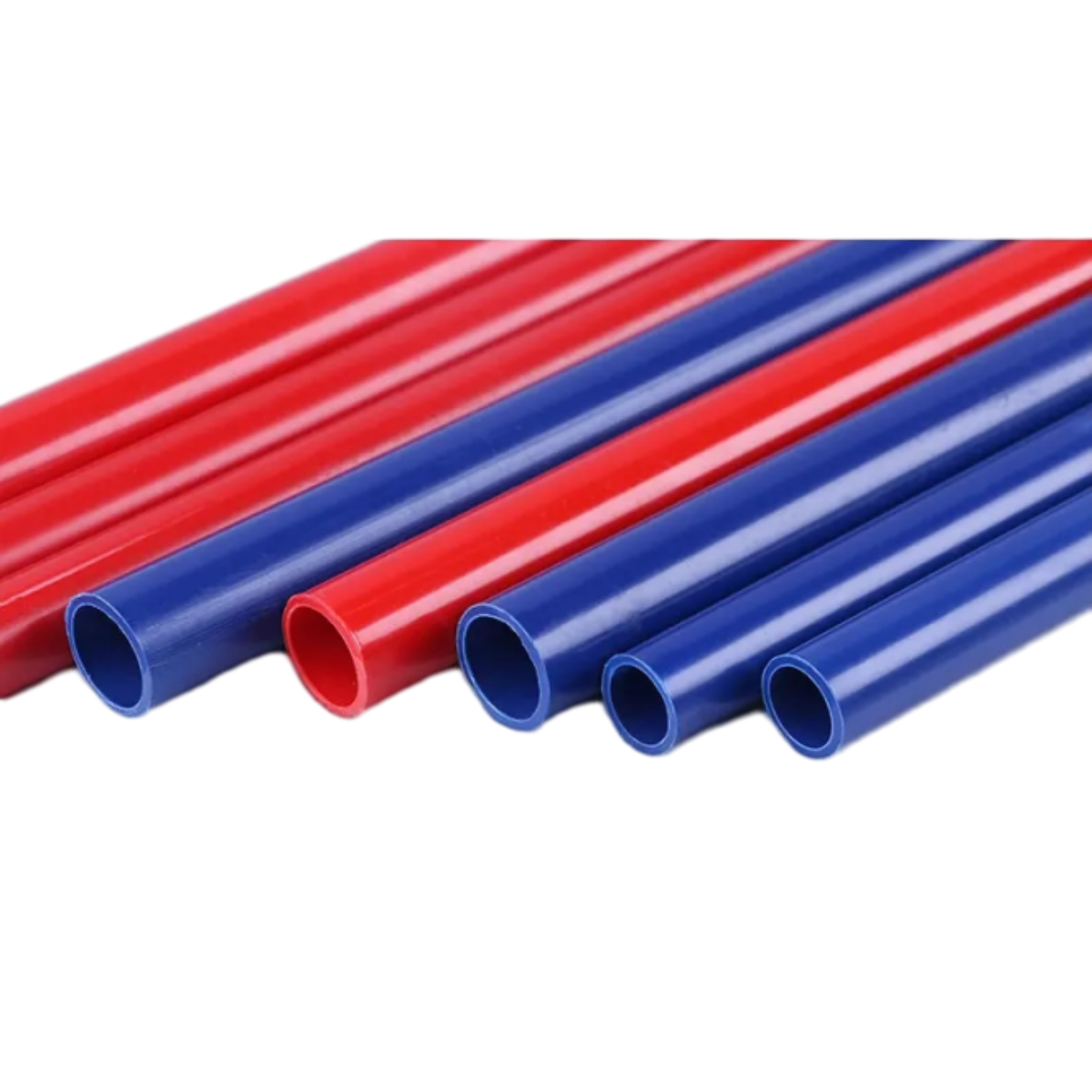

1/2' PVC Electric Protective Pipe - Durable, Lightweight Conduit

In the dynamic landscape of electrical infrastructure, the application of 1/2’ PVC electric protective pipe has grown rapidly, driven by stricter safety regulations, the global trend towards sustainable construction, and increased demand across industrial sectors. This in-depth guide presents latest industry trends, technical parameters, manufacturing process, advantages, and practical application scenarios. Whether you are a procurement manager, EPC project engineer, or a facility operator, this article provides data-driven insights to elevate your product selection and engineering design.

Industry Trends & Market Dynamics

- Global market scale: According to MarketsandMarkets, the global PVC pipe market is valued at USD 61.7 billion (2023) with electrical conduit segment representing over 28% share.

- Safety compliance: Rapid adoption in new energy projects and smart city infrastructure due to compliance with standards such as ISO 4422, UL651, ANSI C80.3.

- Sustainability: Increasing replacement of metal conduits with 1/2’ PVC electric protective pipe for its low carbon footprint and recyclability.

- Major applications: Petrochemical plants, water & wastewater utilities, commercial buildings, data center construction, greenfield industrial parks.

Technical Specifications & Industry Benchmarking

Below is a data table comparing major technical and industry parameters for 1/2’ PVC electric protective pipe versus traditional alternatives. Data is gathered from leading suppliers and certification authorities.

| Parameter | 1/2’ PVC electric protective pipe | Galvanized Steel Conduit | Flexible Corrugated Pipe |

|---|---|---|---|

| Inner Diameter (mm) | 15.8 | 15.6 | 15.5 (nominal) |

| Wall Thickness (mm) | 1.5 - 2.0 | 1.7 - 2.1 | 0.8 - 1.0 |

| Standard Length (m/pc) | 3.0 / 4.0 | 3.05 | 25, 50 rolls |

| Rated Voltage Suitability (V) | ≤ 1000 | ≤ 1000 | ≤ 300 |

| Thermal Insulation | Excellent (≤ 0.19W/m·K) | Medium | Poor |

| Corrosion Resistance | Superb (Highly resistant to acids, alkalis) | Poor (rusts over time) | Good |

| Compliant Standards | ISO 4422, UL651, ANSI C80.3 | UL6, ANSI C80.1 | IEC 61386, RoHS |

| Fire Retardancy | V-0 (UL94), Self-extinguishing | Non-rated | V-2 to V-0 |

| Lifespan (Year) | ≥ 50 | 15~30 | 8-15 |

| Weight (per m, kg) | 0.16±0.02 | 0.42±0.04 | 0.08±0.01 |

Manufacturing Process of 1/2’ PVC electric protective pipe

- Raw Material Mixing: Special grade, lead-free, UV-resistant polyvinyl chloride (PVC) resin is compounded with high-performance stabilizers, lubricants, and fire-retardant additives. This ensures exceptional mechanical properties and long-term weather resistance.

- Extrusion Molding: PVC blend is fed into a high-precision, twin-screw extruder. Controlled heating (165~185°C) achieves optimal plasticization. State-of-the-art dies form the precise 1/2’ internal bore diameter and wall thickness.

- Sizing & Cooling: The extrudate is passed through vacuum sizing calibration tanks to tightly control dimensions, followed by water spray cooling to lock in mechanical strength.

- Automatic Cutting: High-speed fly-knife cutter guarantees length tolerance within ±2mm. Length is marked automatically for traceability.

- Quality Inspection: Each batch undergoes hydrostatic pressure test (3.2MPa, ISO 4422), impact resistance, flame retardancy (UL94 V-0), and dimension checks as per ANSI C80.3.

- Packaging & Storage: Bundled in stacks, each pipe labeled with QR codes for batch tracking, ready for shipment.

Parameter Visualization & Performance Benchmarks

Why Choose 1/2’ PVC electric protective pipe?

- Superior Insulation: Volume resistivity exceeds 1×1014Ω·cm, preventing accidental electric leakage and ensuring maximum safety to personnel and equipment.

- Extended Service Life: Maintains mechanical integrity and color stability for over 50 years under typical outdoor/industrial conditions (ISO 4422 tested).

- Corrosion & Acid Alkali Resistance: Performs in harsh chemical environments where metal pipes fail — especially in petrochemical and wastewater installations.

- Lightweight & Cost-efficient: Up to 60% lighter than metal equivalent, reduces installation labor, transportation, and maintenance outlays.

- Fire Safety Certified: UL94 V-0 grade, self-extinguishing, meets stringent fire safety codes for public, commercial and data center buildings.

- Free of Hazardous Substances: Compliant with RoHS, REACH — suitable for green building and environmentally responsible projects.

- Precision Manufacturing: CNC-die wall thickness control ensures uniformity, virtually zero ovality, seamless cable pulling over long distances.

Manufacturer Comparison

| Supplier | Certifications | Main Markets | Production Volume | Customization | Lead Time (days) |

|---|---|---|---|---|---|

| Horonpipe | ISO 9001, ISO 4422, UL651 | Asia, Europe, MEA | ~5,000 tons/month | Color, cut length, private label | 7–18 |

| JM Eagle | ISO 9001, UL651 | USA, Americas | ~3,400 tons/month | Partial | 12–25 |

| PRINCE Pipes | ISO 14001, BIS | India, Southeast Asia | ~2,900 tons/month | Limited (bulk orders) | 18–28 |

| Polypipe | BS EN, Kitemark | UK, EU | ~2,700 tons/month | Moderate | 14–24 |

Customization & Integration Solutions

- Color Options: Standard light grey (RAL 7035), black (anti-UV), orange (signal), custom RALs for segregation or branding.

- Pre-wired Conduits: Factory pre-insertion of wires or pilot ropes for reduced site labor.

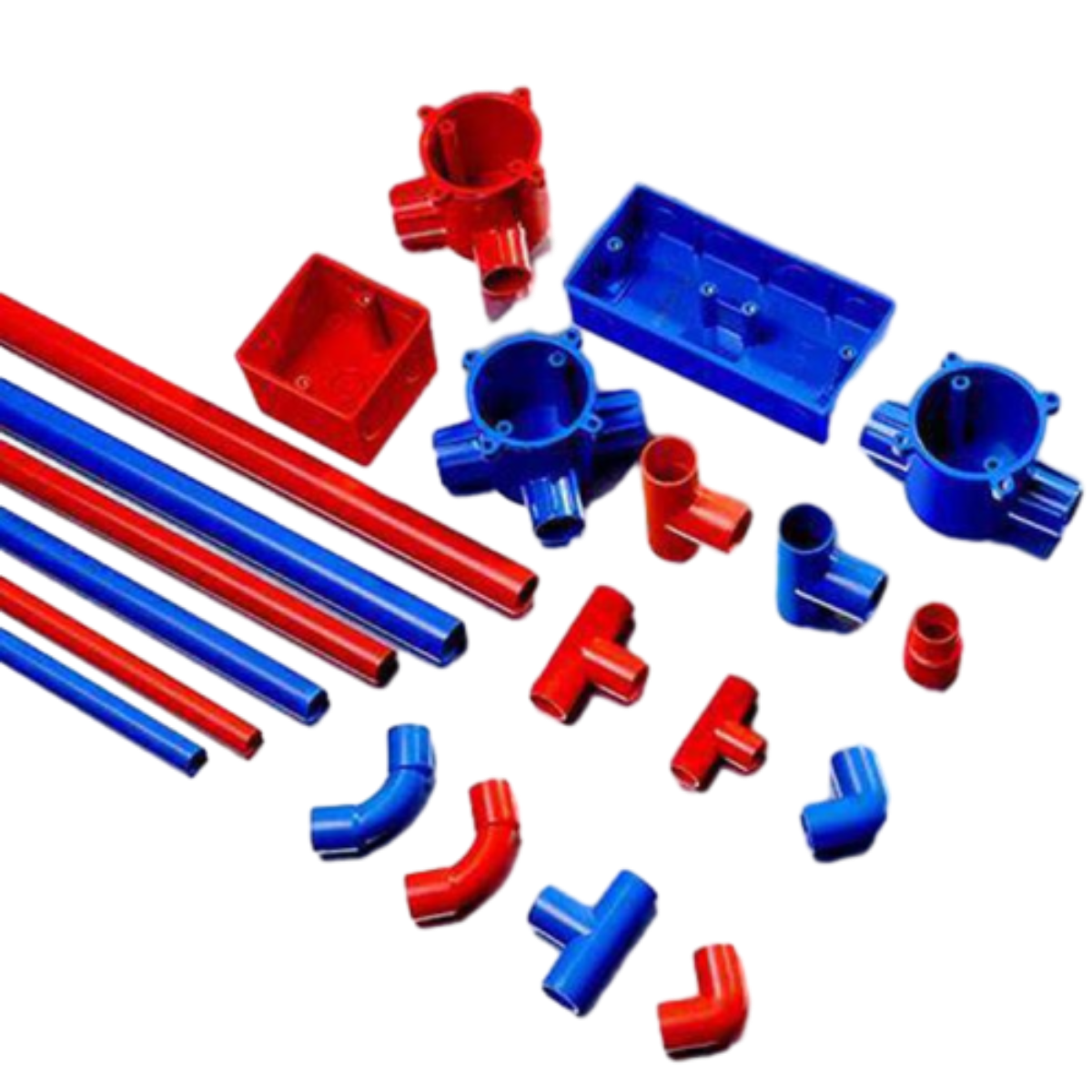

- Jointing: Beveled ends, gasketed, or push-fit connectors for easy onsite assembly.

- Service: OEM logo engraving, QC trace codes, packaging in line with project needs.

- Dimension Range: Customized wall thickness (1.2~3.0mm), lengths (from 1m up to 6m per piece).

Delivery Promise: Responsive 7-18 days lead time from confirmed order (subject to spec), backed by 5-year quality warranty.

Application Case Studies & Client Feedback

Petrochemical Industrial Park, East Asia (2023)

- Project scale: Used over 67,000 meters of 1/2’ PVC electric protective pipe for underground cable runs. Exposed sections showed no embrittlement or color change after summer/winter cycling.

- Testing: Onsite water tightness, mechanical crush, and fire safety passed with 100% compliance (see UL651 standard).

- Feedback: “Installation crew highly appreciated reduced pipe weight and cut ease. Zero warranty claims over 18 months of operation.”

Green Building Office Project, Western Europe

- Requirements: All wiring protection solutions must be RoHS compliant and non-metallic for LEED certification.

- Solution: “Horonpipe’s 1/2’ PVC electric protective pipe was selected for all trunking lines, passing EU fire-safety code and environmental audits.”

Data Center Electrical Upgrade, Southeast Asia

- Challenge: Cable density and tight bends necessitated exceptional flexibility and fire resistance.

- Achievement: “PVC conduits enabled fast installation in cable trays and risers, reducing project time by 31% compared to galvanized conduit.”

Frequently Asked Questions

Expert FAQ on 1/2’ PVC electric protective pipe

What material grade is used for 1/2’ PVC electric protective pipe?

Which international standards does the product comply with?

What are the available pipe dimensions and tolerances?

How does installation of 1/2’ PVC electric protective pipe differ from metal conduit?

What is the product's temperature range & fire rating?

What surface and joint accessories are recommended for professional installation?

Is 1/2’ PVC electric protective pipe suitable for use in corrosive or chemically harsh environments?

Order, Delivery & Support

- Standard lead time: 7–18 days from contract, subject to quantity and special customization.

- Warranty: 5 years against manufacturing and material defects, under standard use.

- After-sales support: 24/7 technical helpline and on-site troubleshooting (via authorized agents).

- Documentation: Full set of delivery inspection record, test certificates, and MSDS as per customer request.

References & Industry Literature

- International standard ISO 4422 for PVC pipe: https://www.iso.org/standard/39489.html

- UL651 Electrical Conduits Listing Information: ul.com/resources/ul-651-standard-pvc-conduit

- Community Forum — Professional Electricians: Mike Holt Enterprises Forum

- Market analysis, application trends, and technical articles: marketsandmarkets.com

- Case studies on chemical resistance and life cycle: plasticsmakeitpossible.com

-

DN500 HDPE Double Wall Corrugated Drain Pipes | Durable & Efficient

NewsJul.31,2025

-

DN25 PPR Water Pipes for Kitchen - Durable & Leak-Proof Plumbing Solution

NewsJul.30,2025

-

HDPE Sprinkler Pipe Manufacturers – Durable Irrigation Solutions

NewsJul.30,2025

-

High-Quality DN150 HDPE Pipes for Gas Delivery – Durable & Leak-Proof

NewsJul.29,2025

-

140mm PVC Drilling Pipe for Efficient Borehole Drilling Solutions

NewsJul.29,2025