Jul . 30, 2025 04:20 Back to list

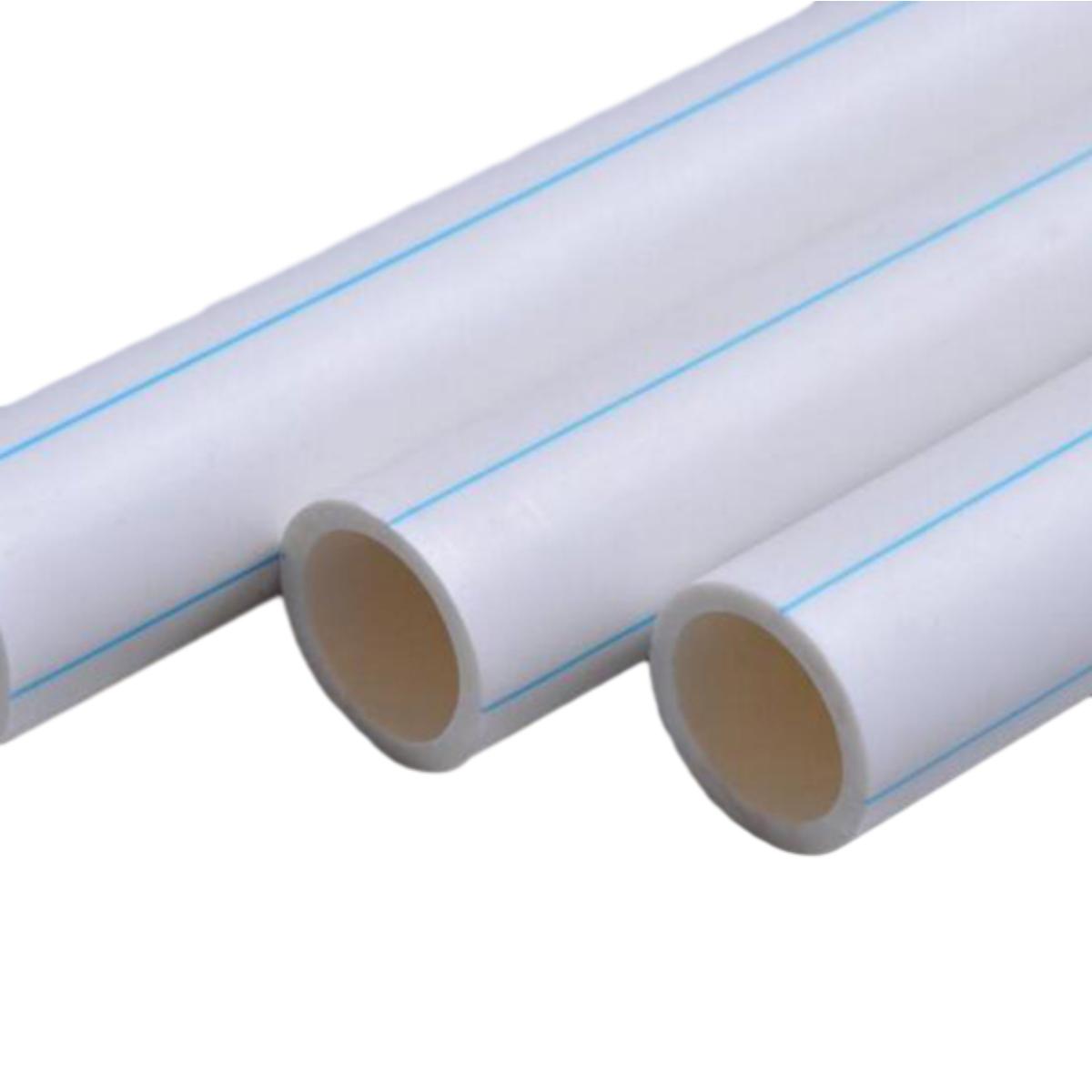

DN25 PPR Water Pipes for Kitchen - Durable & Leak-Proof Plumbing Solution

Explore the features, advantages, and application cases of DN25 PPR water pipes for kitchen through advanced data, detailed manufacturing flow, and industry-leading standards.

1. Industry Trends and Market Insights

The global PPR (Polypropylene Random Copolymer) pipe market is witnessing significant growth. In 2023, the market size exceeded $8.2 billion (MarketsandMarkets, 2023), a direct reflection of increased demand for high-quality, corrosion-resistant piping solutions in residential and commercial kitchens. DN25 PPR water pipes for kitchen have become the industry standard for energy efficiency, hygiene, and longevity, promoted by green building codes and stricter water safety requirements.

- Over 65% of new urban kitchens in Asia–Pacific now specify PPR piping systems (source: ICCA Asia 2023).

- DN25 pipe diameter is the preferred standard for mid-to-large flow and balance of durability and cost in modern kitchens.

- Stringent ISO 15874 and ANSI/NSF 14 certifications are now non-negotiable for imported kitchen piping.

2. Technical Parameters and Specification Table

Below is a detailed specification table for DN25 PPR water pipes for kitchen, with comparisons to typical copper and PVC pipes:

| Parameter | DN25 PPR Water Pipe | Copper Pipe | PVC Pipe |

|---|---|---|---|

| Nominal Diameter | 25 mm | 22 mm | 25 mm |

| Wall Thickness | 4.2 mm (PN 20) | 1.2 mm | 2.5 mm |

| Working Pressure | Up to 20 bar | 15 bar | 10 bar |

| Max Working Temp. | 95°C | 110°C | 60°C |

| Material | PPR (Type 3 Polypropylene Random Copolymer) | 99.9% Pure Copper | PVC-U |

| Service Life | 50+ years (ISO 15874) | 30+ years | 25 years |

| Corrosion Resistance | Excellent | Moderate (subject to scaling) | Good, but less for hot water |

| Certifications | ISO 15874, ANSI/NSF 14 | ASTM B88 | ASTM D1785 |

3. Manufacturing Process Flow of DN25 PPR Water Pipes for Kitchen

The manufacturing process of DN25 PPR water pipes for kitchen involves advanced extrusion, precision quality control, and stringent testing. Compliance with ISO 15874:2012 ensures premium quality. Below is a technology process infographic and key explanations:

- Material: 100% virgin PPR resin (Type 3) ensures density & anti-corrosion.

- Manufacturing: Precision extrusion → Rapid cooling → Automated CNC cutting to DN25 specs.

- Quality Testing: Each pipe undergoes hydraulic, thermal, and visual inspection per ISO 15874.

4. Key Technical Advantages & Application Scenarios

- Exceptional Corrosion Resistance: PPR is chemically inert—unaffected by kitchen detergents, acids, or minerals (versus copper scaling).

- Thermal Stability: Handles boiling water up to 95℃; ideal for dishwashers, hot taps, and culinary uses.

- Low Thermal Conductivity: Reduces heat loss by 37%-54% compared to metals [EN 12524 Reference].

- Hygienic & Lead-Free: No harmful migration—meets EU Drinking Water Directive.

- Longevity: Certified for 50+ years of service by ISO accelerated aging tests (ISO 9080/15874).

Application Scenarios

- Residential Kitchen Water Supply: Smooth interiors for scale-free, taste-neutral, and hygienic water.

- Commercial Kitchens & Catering: Thermal shock resistance stands up to heavy-duty dishwashers and rapid cleaning cycles.

- Hospital & Laboratory Kitchens: No heavy metals or bacterial growth; fully compliant with ANSI/NSF 14 for potable water.

- Green Building: Full recyclability and low environmental impact per LEED v4 standards.

5. Data Visualization: Performance Comparison

6. Leading Manufacturers & Certifications

| Manufacturer | Product Standard | Certifications | Core Markets | Warranty |

|---|---|---|---|---|

| Horon Pipe | DN25 PPR | ISO 15874, ANSI/NSF 14, CE | Asia, EU, Middle East | 15 years |

| Wavin | Tigris PPR | ISO 15874, WRAS | Europe, LatAm | 10 years |

| Aquatherm | Green Pipe | DVGW, DIN, ISO | Global | 10 years |

- Horon Pipe offers factory-direct customization, quick lead times, and robust after-sales support.

- All listed brands adhere to global standards: ISO 15874 for PPR quality, ANSI/NSF 14 for potable water safety.

7. Customization, Delivery, and Customer Service

- DN25 PPR water pipes for kitchen can be customized in color, wall thickness, length, and pressure class (PN 12.5/16/20).

- Delivery Time: Standard models: 5-7 days; Custom: 14-21 days depending on volume.

- Quality Guarantee: Each batch tested per ISO 15874; warranty up to 15 years.

- Support: Free pipeline system layout consultation, installation video guides, and multilingual onsite support.

- Traceability: Every pipe is laser-marked with lot code, manufacturing date, and certification for full lifecycle trace.

8. Application Case Studies & End-User Experience

Smart Home Supply for Midea (2022):

Over 36,000m of DN25 PPR water pipes for kitchen installed in modular kitchens. Feedback: zero scaling, over 43% reduction in maintenance complaints in the first year.

"Switching to PPR eliminated leaks and we noticed smoother water flow. The pipes look new after 18 months of use."

— Facility Manager, Guangdong

Commercial Catering Retrofit, Dubai (2023):

Horon Pipe DN25 system selected for robustness and easy compliance with water standards (NSF 14). Average installation time reduced by 24% compared to copper, based on project logs.

Benefit: Energy bills dropped by 7% monthly due to thermal insulation of PPR lines.

- Experience Highlight: Easy hot-melt socket fusion allows for 50% faster assembly than traditional threading or soldering.

- Maintenance teams confirm long-term water clarity and no taste/odor transfer.

- Customer support response time: 95% of queries handled in 8 hours.

9. FAQ: Technical Questions about DN25 PPR Water Pipes for Kitchen

A1: "DN" stands for "Diameter Nominal", 25 meaning the inner diameter is 25mm. This delivers balanced water volume and pressure—ideal for modern kitchen appliances.

A2: PPR (Polypropylene Random Copolymer) is more suitable for hot and cold drinking water due to its purity, chemical stability, and fusion joint. CPVC is used more for industrial chemicals or high-temp lines, but may leach additives over time.

A3: Globally recognized standards include ISO 15874 (hydrostatic strength, material purity), ANSI/NSF 14 (potable safety), and EN 12201 (European requirements).

A4: It's when the pipe and fitting are heated and fused together—creating leak-free, totally integrated, and chemically bonded connections. No glue or metal fittings required.

A5: Rated by class: PN 16 (16 bar, for standard residential) or PN 20 (20 bar, for high-rise/commercial) per ISO testing for 95°C water and sustained hydraulic load.

A6: Absolutely. They are inert, do not support microbial growth, and have no plasticizer or heavy metal migration. Certified under ANSI/NSF 14 and ISO 15874.

A7: PPR expands ~0.15 mm/m/°C. Proper installation uses expansion loops or sliding supports—full guides provided by the supplier for longer runs.

Industry References:

• Autodesk Piping Forum: PPR vs. PVC in Kitchens

• PM Magazine: PPR Pipe Enters the North American Kitchen Market

• ScienceDirect: Life Cycle of Plastics in Building Pipes

-

HDPE Sprinkler Pipe Manufacturers – Durable Irrigation Solutions

NewsJul.30,2025

-

High-Quality DN150 HDPE Pipes for Gas Delivery – Durable & Leak-Proof

NewsJul.29,2025

-

140mm PVC Drilling Pipe for Efficient Borehole Drilling Solutions

NewsJul.29,2025

-

High-Quality UPVC Column Pipes for Submersible Pumps – Corrosion Resistant

NewsJul.29,2025

-

DN500 HDPE Double Wall Corrugated Drain Pipes for Efficient Drainage

NewsJul.28,2025