Jul . 29, 2025 20:40 Back to list

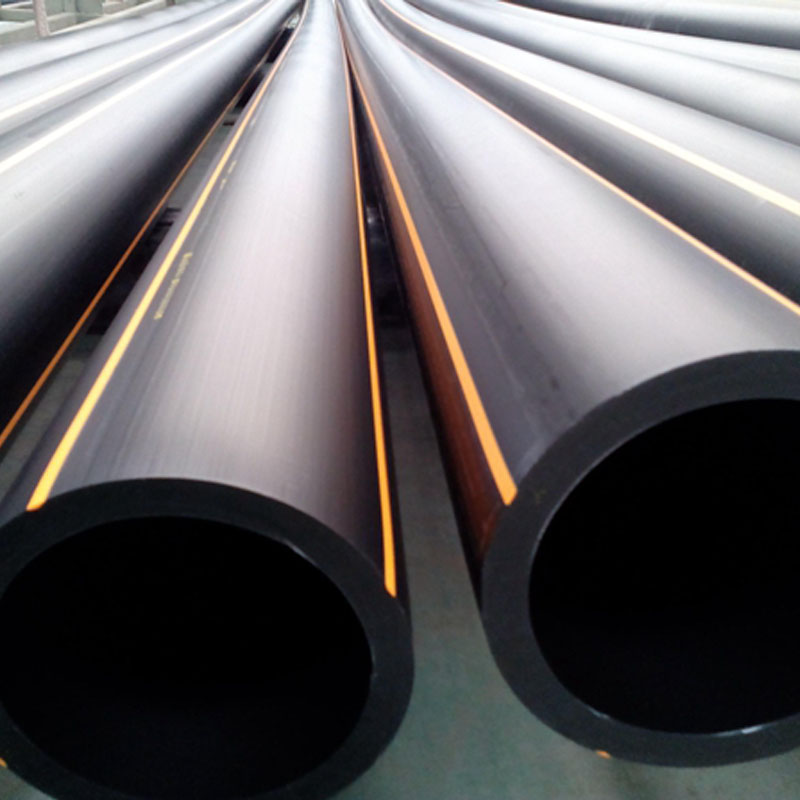

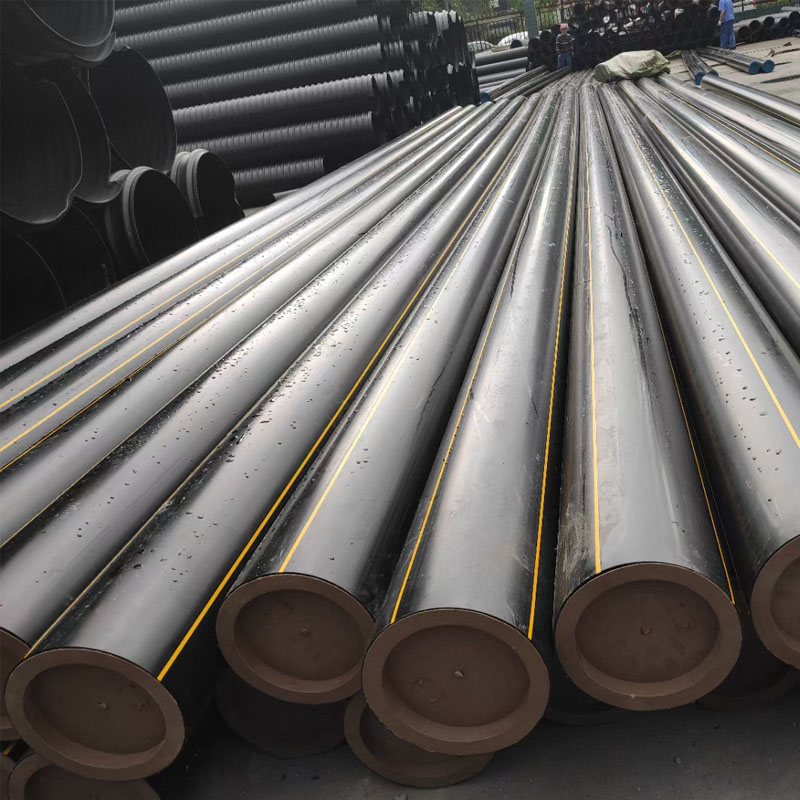

High-Quality DN150 HDPE Pipes for Gas Delivery – Durable & Leak-Proof

In the ever-evolving field of gas transmission, the need for durable, safe, and efficient pipeline solutions is paramount. DN150 HDPE pipes for gas delivery have emerged as the industry benchmark for modern gas distribution networks. Backed by ISO 4437, EN 1555, and ANSI/ASTM standards, these pipelines combine exceptional physical properties with advanced manufacturing technology, providing unparalleled advantages for oil & gas, municipal, and industrial sectors.

Industry Trends of DN150 HDPE Pipes for Gas Delivery

The global HDPE pipe market is valuated at USD 17.6 billion in 2023, with gas delivery pipelines representing over 30% of this segment (source). As urban expansion and gasification projects accelerate in Asia, Africa, and Eastern Europe, DN150 HDPE pipes see a compound annual growth rate (CAGR) of approximately 6.2% (2022–2028). Key industry drivers include:

- Increased adoption of high-density polyethylene (HDPE) for its corrosion resistance and longevity.

- Stringent safety regulations (ISO/EN/ANSI/ASTM) promoting non-metallic piping systems in hazardous areas.

- Service lifespan requirements exceeding 50 years under continuous operation, validated by third-party testing reports.

- Accelerated replacement of aging steel pipelines with PE100-grade DN150 HDPE pipes for gas delivery.

Technical Parameters: DN150 HDPE Pipe Specifications

| Parameter | Standard Value | Test Method / Standard |

|---|---|---|

| Nominal Diameter | 150 mm (DN150) | ISO 4437, EN 1555 |

| Standard Dimension Ratio (SDR) | SDR11, SDR17, SDR21 | ISO 4065 |

| Pressure Rating | ≥ 1.6 MPa (PE100, SDR11) | ISO 12162, ISO 4427 |

| Material Grade | PE100 (High-Density Polyethylene) | ISO 9080 |

| Wall Thickness | 13.7mm (SDR11), 8.8mm (SDR17) | EN 1555-2 |

| Length | 5.8m, 11.8m, or Coil (50~200m) | Factory Customizable |

| Operating Temperature | -40°C to 60°C | ASTM D3350 |

| Color | Black with Yellow Stripes (Gas Standard) | ISO 4437 |

| Lifespan | > 50 years | ISO 9080 |

| Testing/Certification | ISO, EN, ANSI, CE, WRAS | Third-Party Inspection |

Manufacturing Process of DN150 HDPE Pipes for Gas Delivery

Key Points: The manufacturing process for DN150 HDPE pipes for gas delivery uses advanced extruders, in-line ultrasonic flaw detection, and full batch traceability, in compliance with ISO 4437 and EN 1555.

Product Comparison: DN150 HDPE Pipes vs. Competing Materials

| Feature | DN150 HDPE Pipe | DN150 Steel Pipe | DN150 PVC Pipe |

|---|---|---|---|

| Corrosion Resistance | Excellent (no rust, non-reactive to gas) | Poor (requires lining or coating) | Limited (susceptible to stress cracking) |

| Joint Type | Fusion welding (no leakage) | Flanged/butt weld (risk of leaks) | Solvent/Sleeve joint (may leak under pressure) |

| Flexibility | High (min. bend radius 15 x OD) | Low | Medium |

| Installation Speed | Fast (coil options possible, lightweight) | Slow (heavy, requires weld) | Moderate |

| Operating Life | >50 years | 25–30 years | 15–20 years |

| Pressure Capability | 1.6 MPa (SDR11/PE100) | 2.5–4.0 MPa | <1.0 MPa |

| Maintenance Need | Minimal | Frequent (external corrosion checks) | Occasional |

| Typical Applications | Gas delivery, water, mining | Gas, oil, chemicals | Drainage, irrigation |

| Compliance Standard | ISO 4437, EN 1555 | API/ASTM | EN 1452 |

Application Scenarios & Industry Case Studies

- Urban Gas Networks: DN150 HDPE pipes for gas delivery are the piping of choice for city gas supply grids, ensuring safety and leak-free distribution.

- Long-Distance Gas Pipeline: Used for regional gas transportation over 50km+, especially in corrosive or soft soil environments.

- Oil & Gas Extraction Fields: Used in sour-gas and wet-gas lines due to anti-corrosion and UV resistance.

- Industrial Parks: For gas/chemical feed lines in manufacturing and metallurgy industries.

- Mining Operations: Delivery of magnetized gas or compressed air for mineral processing in remote areas.

- Water hammer resistance: ΔP

- Trenchless installation speed improved by 37% versus steel

- 100% zero leak weld joints (fusion weld test pass rate)

Custom Solutions for Specific Project Needs

Every pipeline project requires precision and adaptability. Our DN150 HDPE pipes for gas delivery can be tailor-made for your unique specifications:

- Available SDRs: SDR11 to SDR26, with full pressure test reports

- Custom coil lengths (up to 200m), butt fusion or electrofusion-ready ends

- Color-coded stripes, laser-marked batch tracking, bilingual marking upon request

- High-impact or UV-stabilized grades for extreme climates

- Ultrasonic flaw detection reports upon delivery

Certifications & Industry Endorsements

All DN150 HDPE pipes for gas delivery are manufactured under strict adherence to ISO 4437, EN 1555, ASTM D2513, CE, and WRAS standards, validated by SGS and third-party audits.

All DN150 HDPE pipes for gas delivery are manufactured under strict adherence to ISO 4437, EN 1555, ASTM D2513, CE, and WRAS standards, validated by SGS and third-party audits.

Extensive in-house and external laboratory testing—covering Melt Flow Index, Hydrostatic Strength (20°C/80°C), and Long-term Creep Rupture—ensures highest reliability in both municipal and oil/gas industry applications.

- Warranty: 10 years standard, with service life performance >50 years under ISO/IEC test conditions.

- Lead time: 7–15 days for standard sizes; 20–30 days for custom orders.

- Support: 24/7 hotline, online video guidance, and on-site technical training (where required).

FAQ: Technical Terms & Project Queries

- "Mechanical Properties of HDPE for Gas Pipelines", Gas World Journal, 2023, gasworld.com

- ISO 4437:2023 – Plastics pipes and fittings for the supply of gaseous fuels – Polyethylene (PE), ISO Official

- "HDPE Pipeline Performance in Municipal Gas Networks", Pipeline & Gas Journal, Pipeline & Gas Journal

- Market Analysis – "Global HDPE Pipes Market Size Report 2024": Markets & Markets

- HoronPipe Manufacturer Official Product: horonpipe.com

-

DN25 PPR Water Pipes for Kitchen - Durable & Leak-Proof Plumbing Solution

NewsJul.30,2025

-

HDPE Sprinkler Pipe Manufacturers – Durable Irrigation Solutions

NewsJul.30,2025

-

140mm PVC Drilling Pipe for Efficient Borehole Drilling Solutions

NewsJul.29,2025

-

High-Quality UPVC Column Pipes for Submersible Pumps – Corrosion Resistant

NewsJul.29,2025

-

DN500 HDPE Double Wall Corrugated Drain Pipes for Efficient Drainage

NewsJul.28,2025