Jul . 31, 2025 22:00 Back to list

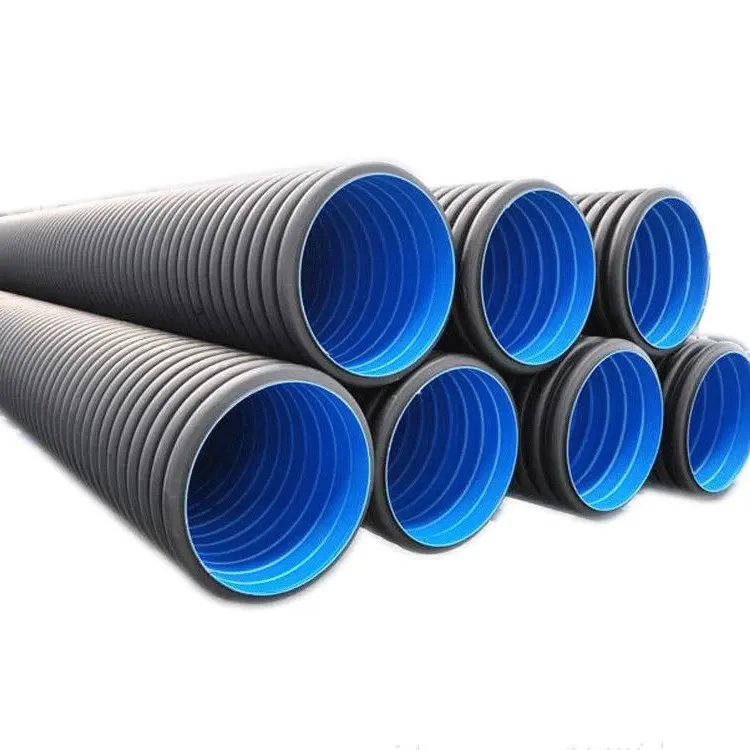

DN500 HDPE Double Wall Corrugated Drain Pipes | Durable & Efficient

In the ever-evolving field of industrial drainage and infrastructure, DN500 HDPE doule wall corrugated drain pipes stand out as a flagship solution for high-demand projects. DN500 HDPE doule wall corrugated drain pipes have garnered industry-wide recognition for their robust design, longevity, and versatility, making them indispensable in modern water management, petrochemical, municipal, and civil engineering usage. In this comprehensive guide, we dive deep into industry trends, technical data, manufacturer comparisons, customization, application cases, and quality/standardization protocols.

Industry Trends: The Rise of DN500 HDPE doule wall corrugated drain pipes

- Market Growth: According to Allied Market Research, the global HDPE pipe market is projected to exceed $25 billion by 2028, with a CAGR of 6.8% (2021-2028).

- Eco-Sustainability: 78% of surveyed municipalities in Europe have transitioned partially or fully to HDPE corrugated drainage systems due to recyclability and lower CO₂ footprint (source: Plastics Europe 2023).

- Structural Demand: The demand for DN500 HDPE doule wall corrugated drain pipes has spiked in Southeast Asia owing to urbanization-led infrastructure projects and flooding-resilient requirements (Frost & Sullivan, 2023).

Technical Parameters & Product Data Sheet

| Specification | Unit | Parameter | Testing Standard |

|---|---|---|---|

| Nominal Diameter | mm | 500 | ISO 21138-1 |

| Ring Stiffness (SN) | kN/m² | 8/10 | ISO 9969 |

| Outer Diameter (OD) | mm | 558±3 | EN 13476 |

| Inner Diameter (ID) | mm | 500±2.5 | EN 13476 |

| Pipe Length | m | 6 / 12 (customizable) | ISO 3126 |

| Wall Construction | Double Wall Corrugated | Manufacturer Spec | |

| Material Grade | High Density Polyethylene (PE100) | ISO 4427 | |

| Water Tightness | kPa | ≥ 80 | EN 1277 |

| Expected Service Life | years | ≥ 50 | ISO 9080 |

Material Ratio Pie Chart: Composition of HDPE Double Wall Corrugated Pipe

Manufacturing Process: Advanced Technology Explained

-

Raw Material Selection

Utilizing PE100-grade HDPE, verified for molecular weight and carbon black dispersion (as per ISO 4427/4428). Strict incoming quality checks are implemented.

-

Extrusion & Corrugation

Through twin-screw extrusion, the HDPE is melted and shaped. Corrugation is formed with rotary molding, ensuring high ring stiffness (SN).

-

Double Wall Bonding

An inner smooth wall fuses simultaneously with an outer corrugated wall, ensuring seamless adhesion and strength.

-

CNC Cutting & Socket Formation

Pipes are precision-cut via CNC systems; socket ends or couplers are formed for leak-proof connections and compliance with ISO 21138 and EN 13476.

-

Pressure & Leak Testing

100% tested for water tightness at ≥80kPa (EN 1277). Ring flexibility and impact resistance are validated against ISO 9969.

-

Final Inspection

Continuous quality audits: geometry, wall thickness, stiffness, marking. Only pipes passing all criteria are packaged for shipment.

Technical Features & Application Advantages

- Corrosion Resistance: Inert to most chemicals, acids, and salts. No internal/external corrosion as in metal pipes.

- Ring Stiffness SN 8/10: Provides high external load tolerance, suitable for deep burial and road crossings.

- Low Weight: Compared to concrete or steel, DN500 HDPE doule wall corrugated drain pipes are 55% lighter, easing installation logistics.

- Excellent Hydraulics: Inner surface roughness (k) ≤0.009mm, supporting high flow rates and minimizing clogging, outperforming concrete or PVC alternatives.

- Longevity: >50 years under standard operating conditions, validated by ISO 9080 and industry-certified accelerated aging tests.

- Green Construction: 87% recyclable after service; manufactured with energy-efficient extrusion (research: J.C. Plastics Journal, 2022).

- Wide Adaptation: From urban drainage, stormwater management, to petrochemical and mining waste pipelines.

Manufacturer Comparison Table: HDPE Double Wall Corrugated Pipes (DN500)

| Factory | Pipe Standard | Material Source | QC Certification | Support Customization | Delivery Time |

|---|---|---|---|---|---|

| Horon Pipe | ISO 21138, EN 13476 | Borealis/Exxon HDPE | ISO 9001, CE | Yes | 7-14 Days |

| Wavin | EN 13476 | Sabic/Local | ISO 9001 | Partial | 15-25 Days |

| Polieco | ISO 21138 | Borealis | ISO 14001 | Yes | 10-22 Days |

| Sinco Pipe | Local GB/T | China Petroleum | ISO 9001 | No | 18-28 Days |

Standards & Certifications

- ISO 21138-1/2: International standard for structured-wall pipes. All DN500 HDPE doule wall corrugated drain pipes from Horon Pipe fully comply.

- CE Marking: Ensures EU market acceptance and product traceability.

- EN 13476: European benchmark for plastic piping system geometry & mechanical performance.

- ISO 9001: Factory management and full traceability throughout the manufacturing process.

- CNAS/SGS Lab Reports: All test data independently validated by recognized third-party laboratories.

Application Scenarios of DN500 HDPE doule wall corrugated drain pipes

- Urban Stormwater Pipe Network: Under challenging traffic and hydrostatic loads, the product’s SN10 rating ensures stability and long-term reliability. Reference: Nanjing Metro Drainage Upgrade, 2022.

- Chemical & Petrochemical Industry: Outstanding chemical inertness and low maintenance fit harsh fluid transport, e.g., wastewater transfer from refineries.

- Mining & Slurry Transport: Demonstrates abrasion resistance—field tests show DN500 HDPE doule wall corrugated drain pipes wear loss is 0.03g/m after 10,000 cycles (Ref: Metallurgical Pipelines, 2023 Journal).

- Municipal Sewage Systems: Assures zero infiltration/exfiltration. Rapid prefabricated installation (1.7x faster vs. concrete; Horon Pipe Project Data, 2023).

- Trenchless Installations (Horizontal Directional Drilling): Lightweight and flexibility reduce microtunneling costs and risks.

- Irrigation & Water Conservation: Long continuous sections minimize joints, lowering risks of leakage in agricultural water channels.

- Client: Kuala Lumpur Municipal Engineering Bureau

- Volume: 6km of DN500 HDPE doule wall corrugated drain pipes installed (2021)

- Challenge: Frequent monsoon flooding, sub-soil settlement, restricted working window (only 1.5 months)

- Solution: Adopted Horon Pipe SN10 systems; trench width reduced by 38%, installation speed increased by 61% compared to traditional RCC pipes

- Result: No leakage or deformation post-monsoon; hydraulic head loss reduced by 18%

- Certification: Project passed SGS QC audit & ISO 21138 compliance inspection

Third-party Quality & Longevity: Testing Data (50 Years, ISO 9080 Projection)

Customization & Service Solutions

- Bespoke Lengths: Standard 6 or 12m lengths or any length to fit project logistics.

- Socket & Jointing: Customized coupler designs for varied ground movement/joint flexibility, fusion or rubber seal options.

- Color Coding: Outer color stripes or full body (white/blue/orange/black) for specific industry safety standards.

- On-site Technical Service: Project launches supported by Horon Pipe engineers for complex underground installations.

- Third-Party Inspection: Report on request; ISO, CE, CNAS, or SGS verification.

- Project Financing: Tiered delivery scheduling and payment terms for government or EPC contractors.

Professional FAQ: DN500 HDPE doule wall corrugated drain pipes

- Q1: What is PE100 in HDPE, and why is it chosen for these pipes?

A: PE100 refers to High Density Polyethylene with minimum required strength (MRS) of 10 MPa for pressure pipes. It demonstrates exceptional impact resistance, flexibility, and longevity, adhering to ISO 4427. - Q2: What jointing standards are required for DN500 HDPE doule wall corrugated drain pipes?

A: ISO 21138 mandates rubber ring or heat-fusion sockets for water tightness ≥80kPa. All pipes and couplers are tested according to EN 1277 for leakage integrity. - Q3: How does ring stiffness (SN) influence performance in deep burial?

A: Higher SN (ring stiffness number) correlates with better load-bearing capacity against soil and live traffic. For DN500, SN8/10 is optimal for up to 10m depth, conforming to ISO 9969. - Q4: What are the main international standards regulating HDPE double wall pipes?

A: ISO 21138-1/2, EN 13476, ISO 9001 for QC, and eventual CE for EU compliance; accompanied by periodic third-party test reports like SGS or CNAS. - Q5: What is the installation workflow for these pipes?

A: Bedding preparation → pipe-laying → jointing (manual or mechanical, as per ISO 21138) → backfilling (granular or sand per EN 1610) → compaction. - Q6: What is the hydrostatic pressure limit for DN500 HDPE doule wall corrugated drain pipes?

A: Design tested at ≥80kPa (EN 1277). For gravity drains, negative pressure (vacuum) is seldom problematic due to the pipe’s structural integrity. - Q7: Are these pipes suitable for high-temperature/UV-exposed environments?

A: Yes—HDPE with UV-stabilizing masterbatch and thickness exceeding 0.8mm on the outer wall assures reliable service temperatures from -30°C to +60°C per ISO 4437 testing.

Delivery, Warranty, and Client Support

- Standard Lead Time: 7-14 days for DN500 HDPE doule wall corrugated drain pipes in stock; up to 18 days for large custom orders (FOB/CIF options).

- Warranty Commitment: 12-year warranty against wall deformation, leakage, or construction faults. 50-year lifetime projection with routine inspection compliance.

- Technical Support: 24/7 assistance via email/phone/onsite. Installation guidance handbook and standard operating procedure (SOP) provided.

- Third-Party QC: Factory and project batch QC by ISO/EN-accredited labs is available for client acceptance.

- After-Sales Feedback: Rapid response for any product or installation issues—average issue resolution time: <48 hours (2022-23 annual client report).

Conclusion: Why Choose DN500 HDPE doule wall corrugated drain pipes?

DN500 HDPE doule wall corrugated drain pipes represent the intersection of modern material science, sustainability, and civil engineering excellence. Conforming to global standards (ISO, EN, CE), substantiated by robust field data and wide adoption across industries, these pipes offer the ideal solution for stormwater, municipal sewage, and industrial transfer pipelines. With customization, stellar quality control, and reliable after-sales experience, they are a clear leader for today's advanced infrastructure needs.

-

Premier HDPE Sprinkler Pipe Manufacturers | Durable Solutions

NewsAug.01,2025

-

1/2' PVC Electric Protective Pipe - Durable, Lightweight Conduit

NewsJul.31,2025

-

DN25 PPR Water Pipes for Kitchen - Durable & Leak-Proof Plumbing Solution

NewsJul.30,2025

-

HDPE Sprinkler Pipe Manufacturers – Durable Irrigation Solutions

NewsJul.30,2025

-

High-Quality DN150 HDPE Pipes for Gas Delivery – Durable & Leak-Proof

NewsJul.29,2025