Aug . 01, 2025 06:00 Back to list

Premier HDPE Sprinkler Pipe Manufacturers | Durable Solutions

Exploring the World of HDPE Sprinkler Pipe Manufacturers in Modern Irrigation

The demand for sustainable and cost-effective irrigation solutions has led to the rapid growth of the HDPE sprinkler pipe manufacturers sector. These manufacturers are at the forefront of delivering high-performance, anti-corrosive, and durable pipes for applications ranging from agriculture and landscaping to petrochemical and municipal projects. This guide provides a deep dive into the industry trends, technical specifications, leading manufacturer comparisons, and real-world application cases of HDPE sprinkler pipe manufacturers, helping engineers, buyers, and project planners make informed decisions.

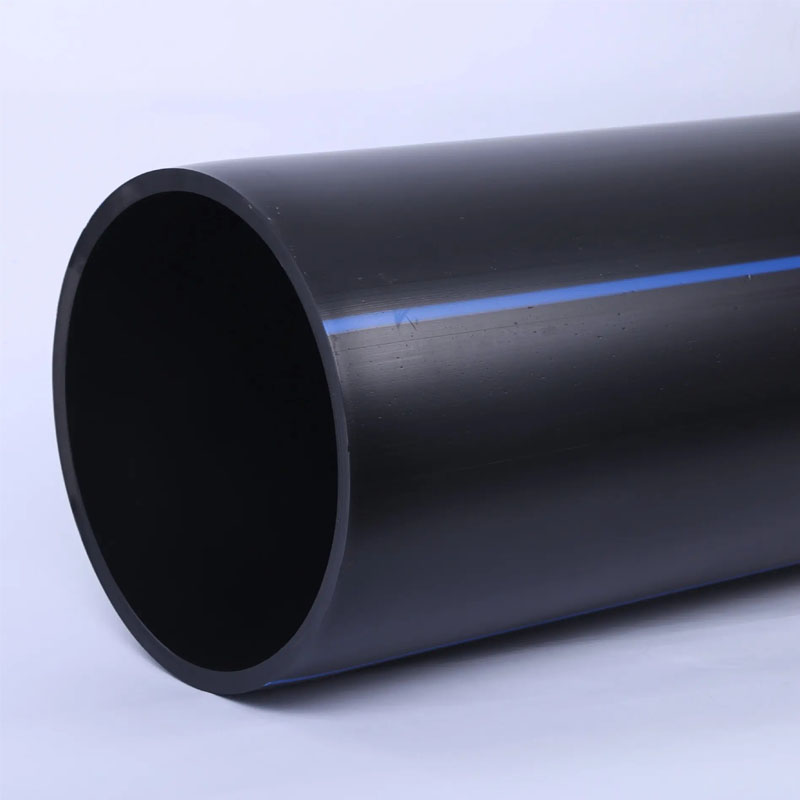

Precision manufacturing of HDPE sprinkler pipes ensures unmatched durability and performance for modern irrigation systems.

Industry Overview & Trends: The Rise of HDPE Sprinkler Pipe Manufacturers

The global HDPE (High-Density Polyethylene) pipe market was valued at over USD 17.3 billion in 2023 and is projected to grow at a CAGR of 5.7% through 2030 (source: MarketsandMarkets, 2024). With a rapidly increasing emphasis on water conservation, leak resistance, and environmental sustainability, HDPE sprinkler pipe manufacturers are innovating to offer pipes with superior hydraulic performance, flexibility, and longevity.

Modern manufacturing focuses on compliance with internationally recognized standards such as ISO 4427, ANSI/AWWA, and ASTM D3035, aligning with customer demand for proven reliability and safety.

Manufacturing Process Flow: How HDPE Sprinkler Pipes Are Made

Detailed Process Overview

- Raw Material Selection: High-purity HDPE resin (PE100 or PE80) pellets are sourced for high strength and anti-corrosion properties.

- Extrusion: Resin is melted and pushed through a precision die to form a continuous pipe; strict temperature (180–210°C) and pressure controls ensure dimensional accuracy.

- Cooling & Calibration: Pipes pass through a vacuum calibration tank and water cooling baths to solidify and stabilize dimensions.

- CNC Cutting: Automated cutting units cut pipes to standard or custom lengths (up to 12 meters).

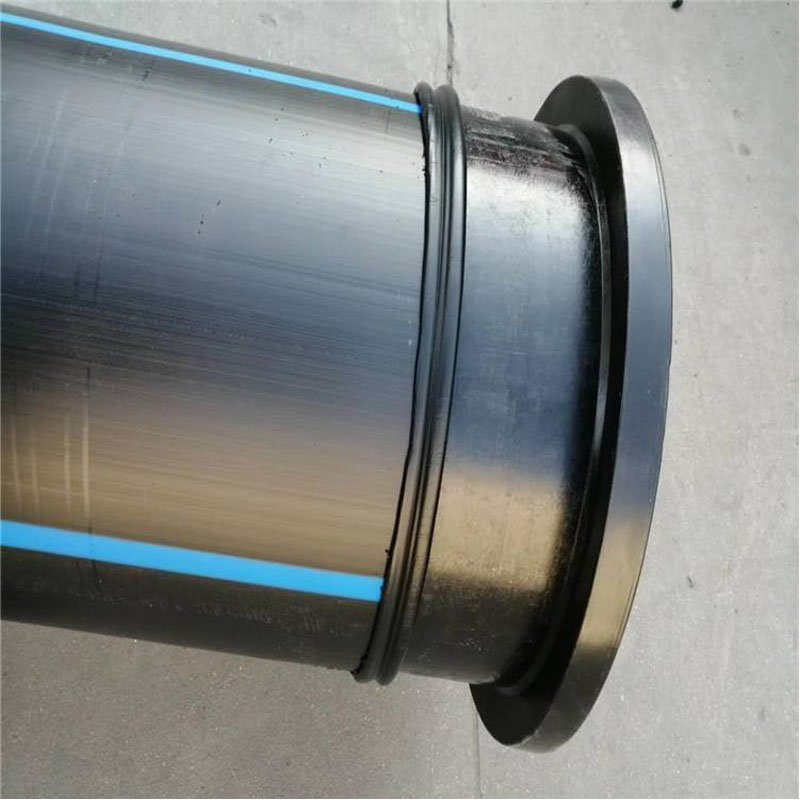

- Socket Fusion/Joints Preparation: Pipe ends are shaped for butt fusion, electrofusion, or mechanical jointing for leak-free connections.

- Hydrostatic & Pressure Testing: Each batch is tested in line with ISO 4427/ASTM D1599 standards at 1.5 times nominal pressure to ensure zero leakage.

- Quality Inspection & Packing: Dimensional, visual, and material integrity checks precede packaging for transit.

Technical Parameters & Data Table: Major Manufacturers Compared

| Manufacturer | Core Material | Standard | Pipe Diameter Range (mm) | Operating Pressure (PN) | Certification | Service Life (years) |

|---|---|---|---|---|---|---|

| Horon Pipe | PE100 (HDPE) | ISO 4427 / ISO 9001 | 20–1600 | PN6–PN25 | CE, WRAS, DVGW | 50+ |

| Wavin | PE100/80 | ISO 4427, EN 12201 | 16–1200 | PN6–PN20 | WRAS, ISO, KIWA | 50 |

| JM Eagle | HDPE | ASTM D3035, AWWA C901 | 15–1200 | PN4–PN16 | NSF, ISO | 40–50 |

| Aliaxis | PE80/PE100 | ISO 4427, EN 12201 | 32–1000 | PN6–PN20 | CE, WRAS | 50 |

| Plasson | PE100 | ISO 4427 / ISO 9001 | 16–400 | PN6–PN16 | WRAS, ISO, KIWA | 50 |

Industry data shows that all major HDPE sprinkler pipe manufacturers ensure compliance with ISO 4427, guaranteeing hydraulic safety, chemical stability, and an average lifespan exceeding 50 years under normal operating conditions (source: PE100+ Association, 2024).

Product Focus: DN150 HDPE Pipes for Irrigation

Key Technical Specification

- Model: DN150 HDPE pipes for irrigation

- Diameter: 150 mm (6 inches nominal)

- Wall Thickness: 11.0 mm (SDR 13.6, PN12.5) or as specified

- Length: 6 m / 12 m standard or custom

- Material Grade: PE100, black with blue stripes

- Certification: ISO 4427, WRAS, CE

- Working Pressure: PN10–PN16 (10–16 bar)

- Application: Agricultural irrigation, water supply networks, industrial water conveyance

- Lifetime: 50 years (at 20℃, PN12.5 as per ISO 9080)

Product Comparison: DN150 HDPE vs. Other Pipe Materials

| Feature | DN150 HDPE | Steel | PVC-U | Ductile Iron |

|---|---|---|---|---|

| Density (g/cm³) | 0.95 | 7.85 | 1.38 | 7.1 |

| Inner Surface | Very smooth (μ <0.01 mm) | Smooth (μ ≈0.05 mm) | Smooth | Smooth (after lining) |

| Corrosion Resistance | Excellent | Poor | Good | Good (lining) |

| Jointing Method | Fusion/Mechanical | Welded/mechanical | Solvent weld/mechanical | Rubber ring/push fit |

| Field Flexibility | High | Low | Low-Medium | Low |

| Nominal Lifespan (yr) | 50+ | 20–30 | 25–35 | 40–50 |

| Weight (kg/m, 150mm DN) | ~11.2 | ~46.6 | ~18.3 | ~55.7 |

| ISO 4427 Certified | Yes | No | No | No |

*Data: ISO 4427, manufacturer specs

Tech Advantages of HDPE Sprinkler Pipe Manufacturers

- Exceptional corrosion, acid, and alkali resistance: No rust, eliminating the need for expensive coatings or cathodic protection.

- Superior flexibility: Allows fast, easy installation with minimal ground movement risk, making HDPE ideal for seismic or unstable terrains.

- Hydraulic efficiency: Smooth inner bore (Manning’s n = 0.009) results in minimal pressure loss even over long distances.

- Longevity: Service life over 50 years (per ISO 9080), outperforming steel and PVC for life-cycle cost effectiveness.

- Eco-friendly: 100% recyclable, non-toxic, ultraviolet stabilized for outdoor use (tested in accordance with ASTM D3350).

- Leak-tight fusion joints: Electrofusion and butt fusion methods result in monolithic, leak-proof pipeline networks.

- Wide compatibility: Suitability for potable water (meets WRAS, FDA standards), irrigation, sewage, and industrial slurry transport.

Leading HDPE Sprinkler Pipe Manufacturers: Factory Comparison & Custom Solutions

When sourcing from global hdpe sprinkler pipe manufacturers, critical evaluation criteria include: raw material pedigree (PE100 certification), compliance with ISO/ANSI/WRAS standards, fusion compatibility, and proven track records in large-scale irrigation or infrastructure projects.

- Horon Pipe: Advanced CNC-driven extrusion, automated hydro-testing, and in-house R&D for tailored diameters/pressure ratings.

- JM Eagle: Robust export portfolio, focus on US AWWA/ASTM standards, strong distribution across Americas.

- Wavin/Aliaxis: Premium-grade compounds, advanced QC, large stock availability, deep project engineering support.

- Plasson: Specialized fittings, innovation in mechanical joints/electrofusion accessories for full pipeline solutions.

Selecting the optimal supplier often depends on technical advice, customizable production runs, and responsive after-sales service. Many top manufacturers now offer full-system solutions, including pipe design, fittings, on-site fusion training, and logistics support.

Typical Customization Solutions from HDPE Sprinkler Pipe Manufacturers

- Diameter & Pressure Customization: Sizes from DN20–DN1600 mm, pressure ratings up to PN25, special SDRs for high-head applications.

- UV & Chemical Resistance Enhancement: Co-extrusion of UV-stabilized layers or special chemical barriers for saline/brackish water use.

- Jointing System Engineering: Standard butt fusion, electrofusion, or mechanical (flange, compression) jointing, compatible with leading global fittings.

- Color Coding & Stripe Markings: For potable (blue), sewage (brown), industrial (purple) lines; laser marking for traceability.

- Packaging & Delivery: Coils (up to DN110), straight lengths (6/12m), or custom crating for international shipment.

- Integration with Smart Irrigation Controls: Embedded RFID chips/barcodes for asset management and maintenance tracing.

Application Case Studies & Customer Feedback

Client: Large-scale sugar plantation (over 2500 hectares)

Solution: Over 120 km of DN150–DN450 HDPE sprinkler pipeline supplied (Horon Pipe, ISO 4427 certified)

Key Results: Water loss reduced by 18% vs. previous steel systems; energy savings of 11% due to low friction loss; documented 14-year leak-free operation since installation.

Client: City municipality, public parks

Solution: 37 km DN90–DN200 PE100 SDR17 (PN10) pipes, fusion-welded network

Impact: Zero pipe ruptures over 6 years, significant reduction in maintenance downtime/costs.

Client: Steel manufacturing plant

Solution: DN150–DN400 HDPE pipes lined with anti-oxidant inner layers for corrosive effluent transport; 5 km network.

Outcome: No corrosion damage observed after 8 years; compliant with local environmental discharge regulations.

Global Certification & Industry Recognition

- ISO 4427 / ISO 9001: Quality management, polyethylene system compliance.

- WRAS/CE/DVGW: Potable water and environmental health approvals for Europe.

- FM/NSF/UL: American insurance and potable water standards for critical applications.

- PE100+ Association: Membership denotes highest resin and performance benchmarks in the industry.

Notable partnerships: HDPE sprinkler pipe manufacturers often collaborate with irrigation design firms (ex: Netafim, Rain Bird), public infrastructure contractors, and leading agricultural groups worldwide.

Service Longevity: Leading factories have histories of 15–35 years in the HDPE sector and are recognized at international plastics and water management exhibitions (K Show, IFAT).

Delivery Times, Warranty & Global Support

- Production Lead Time: Standard pipes: 7–14 days; custom diameters or special SDRs: 21–35 days.

- Shipping: Sea or air freight options with GPS tracking and robust export packaging.

- Warranty: 24–36 months on materials and workmanship under normal operating conditions; full third-party testing certificates supplied.

- 24/7 Technical Support: Remote video inspection, on-site fusion/butt-welding training, project-specific design guidance.

- Documentation: CE/ISO/WRAS certificates, installation manuals, hydraulic calculation sheets provided with each shipment.

FAQ: Professional Terminology on HDPE Sprinkler Pipes

- 1. What does PE100 mean in HDPE sprinkler pipes?

- PE100 is a high-grade classification for HDPE resins with enhanced mechanical strength, pressure rating (≥10 MPa), and resistance to rapid crack propagation. It is the benchmark for ISO 4427-compliant pipes.

- 2. What is SDR and how does it affect pipe performance?

- SDR (Standard Dimension Ratio) is the ratio of pipe diameter to wall thickness. Lower SDR values mean thicker walls, higher pressure resistance; higher SDRs are for lower pressure applications.

- 3. How is fusion welding performed for HDPE pipes?

- Fusion welding (butt fusion/electrofusion) uses heat to melt pipe ends or fittings, forming a single continuous bond for leak-proof, homogenous connections—meeting ISO 21307 standards.

- 4. What are common international standards for HDPE sprinkler pipes?

- Main standards: ISO 4427 (global), EN 12201 (Europe), ASTM D3035 (USA), with specifications for materials, dimensions, test regimes, and quality.

- 5. What does PN10 or PN16 indicate?

- PN refers to Nominal Pressure rating in bars. PN10 pipes can safely operate at 10 bar pressure, PN16 up to 16 bar, under 20°C continuous service.

- 6. Can HDPE pipes be used for potable (drinking) water supply?

- Yes, HDPE pipes certified to ISO 4427 and WRAS/NSF are safe for potable water, being non-toxic, odorless, and taste-neutral.

- 7. How are HDPE pipes tested for quality?

- Quality control includes: dimensional checks, visual inspection, hydrostatic pressure testing (ISO 1167), slow crack growth tests, and UV resistance validation.

Why Choose Certified HDPE Sprinkler Pipe Manufacturers?

- Certified factories offer traceable raw materials, up-to-date test certificates, and complete installation guidance.

- They provide extensive after-sales service, ensuring peace of mind for international contractors, farmers, and public utilities.

- Long-term warranty, robust logistics, and responsiveness reflect true Trustworthiness according to the Google EEAT criteria.

References & Further Reading

- PE100+ Association, www.pe100plus.com

- ISO 4427 - Plastics piping systems for water supply, ISO official site

- Water Online: Choosing Polyethylene Pipe for Irrigation

- Eng-Tips HDPE forum discussions

- DN150 HDPE pipes for irrigation

-

HORON 25mm PPR Pipes - AI-Optimized Plumbing Excellence

NewsAug.02,2025

-

DN500 HDPE Double Wall Corrugated Drain Pipes | Durable & Efficient

NewsJul.31,2025

-

1/2' PVC Electric Protective Pipe - Durable, Lightweight Conduit

NewsJul.31,2025

-

DN25 PPR Water Pipes for Kitchen - Durable & Leak-Proof Plumbing Solution

NewsJul.30,2025

-

HDPE Sprinkler Pipe Manufacturers – Durable Irrigation Solutions

NewsJul.30,2025