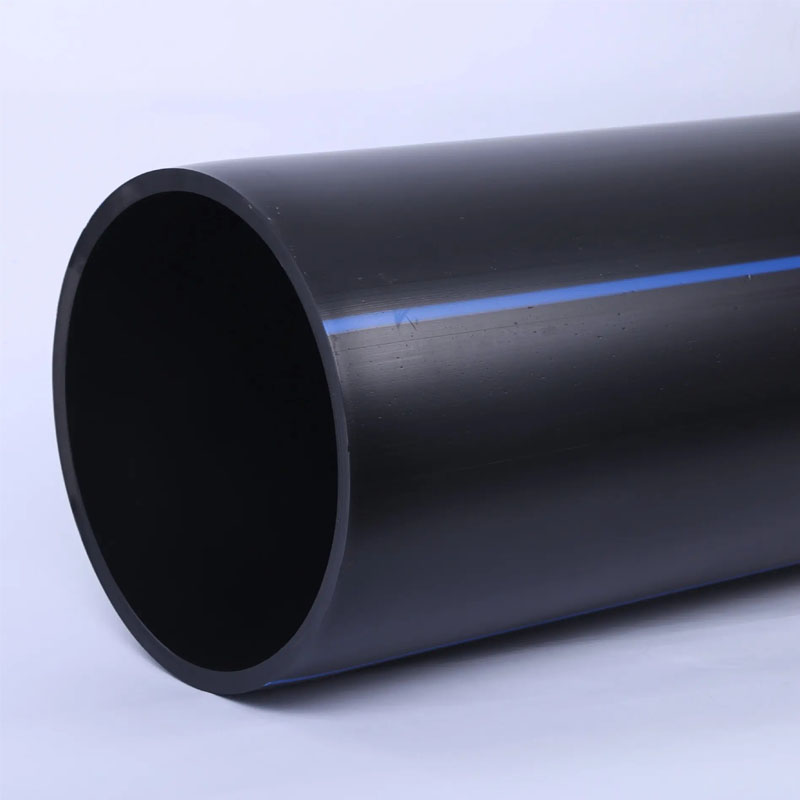

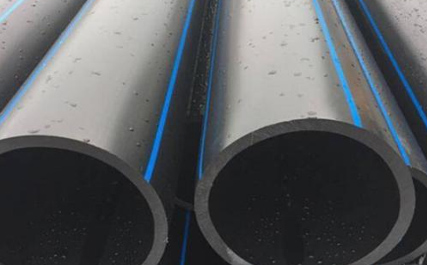

DN150 HDPE pipes for irrigation

We can provide different diameters from 20mm to 2000mm with different pressure gauges 0.6Mpa, 0.8Mpa, 1.0Mpa, 1.25Mpa, 1.6Mpa, and small diameters under 90mm can be produced, packed and transported in coils.

Generally we adopt PE100 grade material to ensure the quality, Meanwhile conforming to the standards GB, DIN,BS,ANSI,SCH40,SCH80.

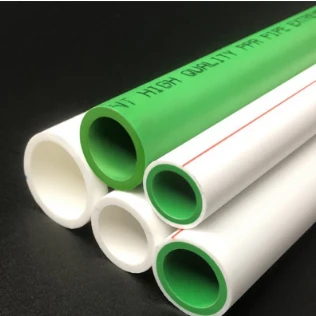

1)Nontoxic and sanitary: HORON HDPE pipe raw material is nontoxic and tasteless, and it passes the strictest health testing, so it belongs to “green” building material, which can prevent scale-forming and improve the water quality.

2)Low flow water resistance. The smooth inner wall for the HORON HDPE pipe is very conducive to water transportation, Under the same conditions, its delivery capacity can increase by 33% compared to steel pipes and other metal pipes which are much rougher in their inner surfaces.

3)Lower Maintenance Costs. HORON HDPE pipe has resistance to cold and hot weather, so it’s erosion-proof, which greatly reduced the costs on human labor, machines, maintenance and replacement, and meanwhile improving work efficiency.

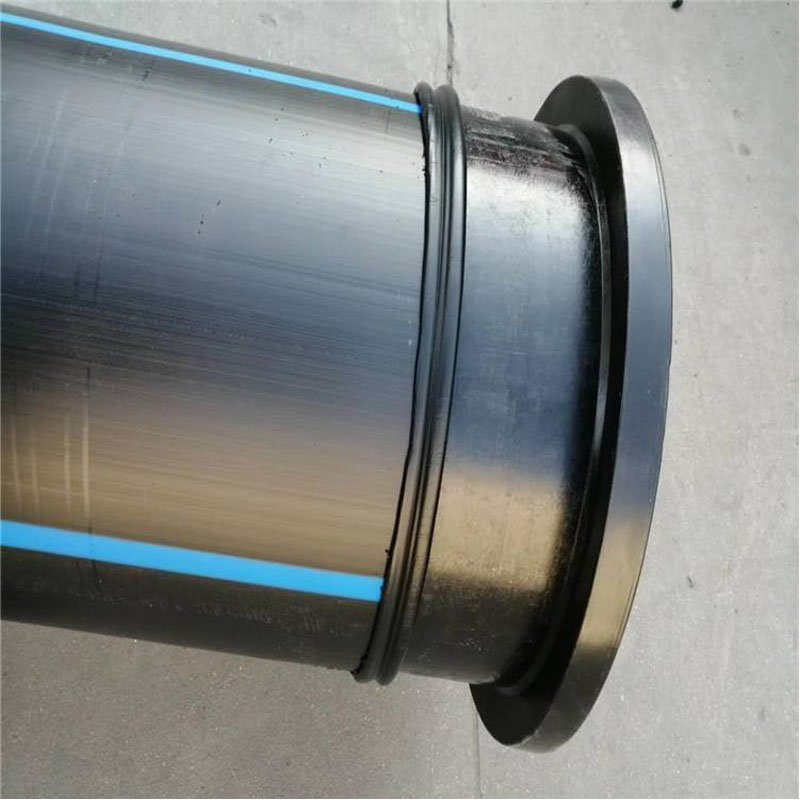

4)No water Leakage. HORON HDPE pipes are interlinked in the ways of butt fusion using welder or electric melting fusion technology, which are both reliable to keep the the strength of joint points, so water leakage can be excluded.

5)High Resistance For Scratch. HORON HDPE pipe is FIVE times the wear resistance of the steel pipe, which means HDPE pipe can keep a much longer service life span with a much better economical benefit.

6)Convenience in Installation. HORON HDPE pipe could be installed in a volatile conditions such as in the trench underground, under the water, in the mud or in the open air ground, so there is no restriction for the the site construction and installation.

Related News