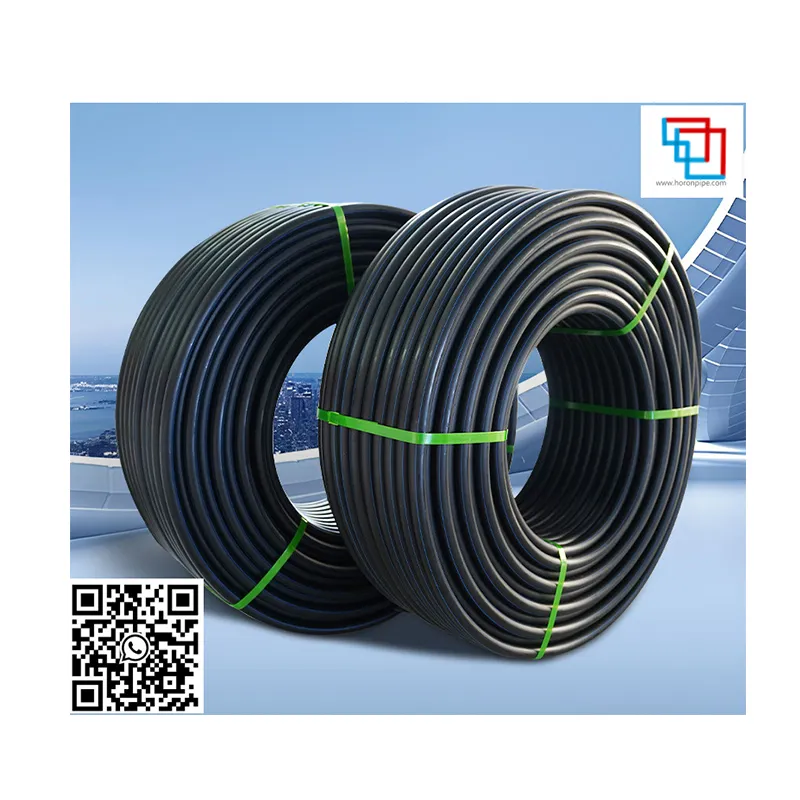

Industry Trends: Evolution in 32mm HDPE Pipes in Coil Technology

The global HDPE (High-Density Polyethylene) pipes market, valued at over $17.5 billion USD in 2023 (Grand View Research), is projected to achieve a CAGR of 5.1% through 2030. 32mm HDPE Pipes in Coil are positioned at the forefront of this rapid market expansion due to their distinctive properties—exceptional flexibility, anti-corrosion capability, and high flow efficiency—making them the preferred solution for pressurized systems, potable water, sewage, and irrigation networks.

Main Advantages Driving Adoption

- Chemical & Corrosion Resistance: Superior performance in aggressive soil and fluid environments, minimizing maintenance.

- Flexibility & Coiling: Coiled delivery up to 100m/roll unlocks rapid installation and fewer joints, a critical advantage over rigid piping (see comparison below).

- Lower Leakage Rate: Fusion-welded joints, as opposed to mechanical connections, virtually eliminate leaks—a key concern in municipal projects (WaterWorld).

- Lightweight: Facilitates transport and handling even in constrained construction sites.

- Adaptability: Suitable for potable water, chemical transport, compressed air lines, agricultural irrigation, and cable conduits.

- Full Recyclability: HDPE pipes are 100% recyclable at end-of-life, supporting sustainability targets in infrastructure.

32mm HDPE Pipes in Coil: Technical Parameters Table

| Property | Specification | Industry Standard | Test Method |

|---|---|---|---|

| Material | PE100/PE80 | ISO 4427 / EN 12201 | Resin Identification |

| Diameter (Outer) | 32mm ± 0.3mm | ISO 3126 | Caliper ICC |

| Wall Thickness | 2.0mm - 3.0mm* | ISO 4065 | Micrometer Test |

| Standard Coil Length | 50m / 100m / 200m | Manufacturer (Customized) | Visual/Coil Counter |

| Pressure Rating | PN6/PN8/PN10/PN12.5/PN16 | ISO 4427 | Hydrostatic Test |

| Density | 0.945 - 0.960 g/cm³ | ISO 1183 | Density Gradient |

| Ring Stiffness | > 8 kN/m² | ISO 9969 | Deflection Test |

| UV Resistance | Yes / Black Carbon 2-2.5% | ISO 4437 | Accelerated Aging |

| Service Life | > 50 Years | ISO 9080 | Extrapolation Test |

| Certification | WRAS, ISO, CE, SGS | - | - |

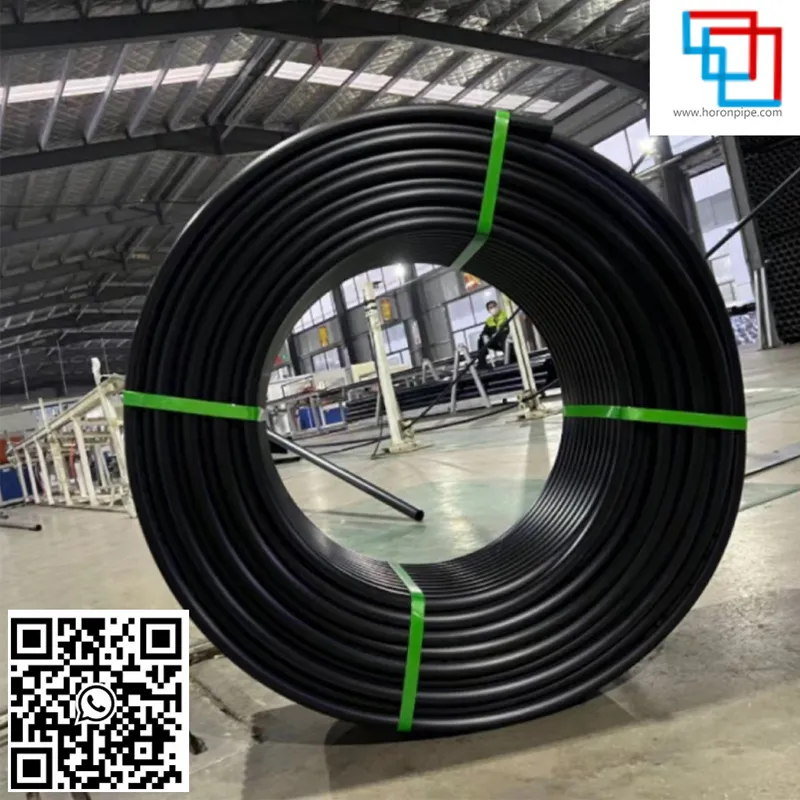

Technical Diagrams: Manufacturing Flow & Quality Control

Manufacturing Process of 32mm HDPE Pipes in Coil

PE100 Raw Resin Selection

Extrusion

Calibrating & Cooling

Coiling & Cutting

Testing & Packing

Manufacturer Comparison: 32mm HDPE Pipes in Coil Suppliers & Custom Options

| Manufacturer | Material Grade | Coil Length Options | Pressure Class | Certifications | Price Range (per m) | OEM/ODM |

|---|---|---|---|---|---|---|

| Horon Pipe | PE100/PE80 | 50/100/200m | PN6-PN16 | ISO, SGS, WRAS | $0.33 - $0.50 | ✔ Yes |

| Brand X (EU) | PE100 | 50/100m | PN6-PN12.5 | ISO, CE | $0.45 - $0.60 | ✗ No |

| Brand Y (Asia) | PE80 | 100/200m | PN6-PN10 | ISO | $0.29 - $0.41 | Partial |

| Local Supplier | PE80/Recycle Mix | 100m | PN6-PN8 | None/Basic Test | $0.23 - $0.30 | No |

Visual Data: 32mm HDPE Pipes in Coil Performance Metrics

Customized Solutions: Tailoring 32mm HDPE Pipes in Coil for Industry Needs

- Color Coding for Application: Blue (potable water, WRAS/NSF certified), Black (multi-purpose), Yellow (gas), Green (sewer/drainage) — all UV-stabilized.

- Pressure Ratings: Supplied per project hydraulic analysis; up to PN16 verified by ISO 4427 hydrostatic testing.

- Length & Jointing: Factory coiling to 50, 100, or custom meterage; compatible with butt fusion, electrofusion, or mechanical couplings.

- Connection Customization: Pre-welded stub ends, flanges, or compression fittings available for quick field deployment.

Application Scenarios & Case Studies: 32mm HDPE Pipes in Coil in Action

Case Study 1: Municipal Water Network Upgrade — Philippines, 2023

- Project Overview: 32mm HDPE Pipes in Coil deployed over 18 kilometers for a tertiary drinking water grid serving 50,000 residents.

- Challenges: Hilly terrain; required minimizing joints and trench time.

- Solution: 100m coil rolls with butt fusion: reduced installation time by 86% versus standard 6m-pipe, with zero reported leaks after 1-year operation.

- Certification: Compliant with ISO 4427, local health authority WRAS equivalent.

Case Study 2: Industrial Plant Chemical Feed, Germany, 2022

- Scenario: Corrosive sodium hypochlorite transport. Replaced steel to avoid pitting and prolong uptime.

- Performance: HDPE PE100 pipes delivered >25% energy savings (lower friction loss) and maintenance-free operation in first 2 years.

- Validation: Independent testing to EN 12201, routine non-destructive weld checks passed.

Case Study 3: Irrigation Network, Morocco, 2024

- System: Drip irrigation on 600 hectares, using 32mm HDPE Pipes in Coil for mains and laterals.

- Outcome: 30% reduction in water loss compared to PVC; field survey confirmed resilience to surface temperature extremes (+62°C summer peaks).

Water supply and distribution, agricultural irrigation, mining slurry lines, cable conduit protection, gas distribution, industrial effluents, and more.

Quality Assurance & Certifications

- ISO 4427 / EN 12201: Covers complete testing from resin to finished pipe; ensures mechanical integrity and long-term pressure resistance.

- SGS/CE/WRAS: Confirms material safety for potable water and chemical stability.

- Lab Testing Data (SGS, 2023): Random sample: Max sustained pressure (8760 hr), OIT ≥ 20 mins (oxidation induction time), density and MFR confirmed to ISO 1133.

- Field Lifetime: Over 50-year service confirmed by extrapolative testing under ISO 9080/12162.

Warranty: 10-year product quality warranty, full traceability.

Technical Support: Engineering advisory, on-site training for fusion welding, on-call customer service.