Aug . 03, 2025 05:40 Back to list

HORON 25mm PPR Plumbing Pipes - AI-Enhanced & Reliable

The global plumbing industry is witnessing a profound transformation, driven by advances in material science, increasing regulatory standards, and greater demand for longevity and performance. Among the premier solutions in this domain, HORON 25mm PPR Plumbing Pipes (official product page) stand out, blending robust technical parameters with unrivaled field experience. This in-depth report investigates the core advantages, production process, certifications, competitive benchmarks, customization capabilities, and real-world deployment of HORON 25mm PPR Plumbing Pipes.

Modern HORON 25mm PPR Plumbing Pipes system on-site

Modern HORON 25mm PPR Plumbing Pipes system on-site

Industry Trends & Market Dynamics in PPR Plumbing Solutions

With the global PPR (Polypropylene Random Copolymer) pipe market predicted to reach USD $8.3 billion by 2028 (MarketsandMarkets), more stakeholders are moving from legacy PVC or copper systems to advanced, eco-safe options. Factors driving this surge include:

- SustainabilityPPR is fully recyclable and non-toxic, supporting green building codes.

- Corrosion Resistance Unlike galvanized steel or copper, PPR resists scale and rust formation.

- Thermal & Chemical Stability Suitable for hot/cold water, industrial chemicals, and food-grade installations.

- Installation Efficiency PPR enables quick welding or mechanical joint assembly.

- Longevity Service life typically exceeds 50 years under certified use conditions.

Technical Parameters of HORON 25mm PPR Plumbing Pipes

| Parameter | Specification | Industry Standard |

|---|---|---|

| Nominal Diameter (DN) | 25 mm | ISO 15874 / DIN 8077/8078 |

| Material Grade | PPR-100 (Random Copolymer Polypropylene Type 3) | ISO 15874 |

| Wall Thickness (SDR 6/7.4/9) | 2.3 / 2.8 / 3.5 mm | EN ISO 15874-2 |

| Working Temperature | -10°C ~ +95°C | ISO 10508 |

| Max. Pressure Rating | Up to 2.5 MPa @ 20°C | DIN 8077 |

| Service Life | ≥ 50 Years | ISO 9080 |

| Applications | Hot/Cold Water, Heating, Industrial Fluids, Drinking Water | ISO 15874 GB/T 18742 |

| Certifications | ISO 9001, ISO 14001, CE, WRAS, SGS Tested | International |

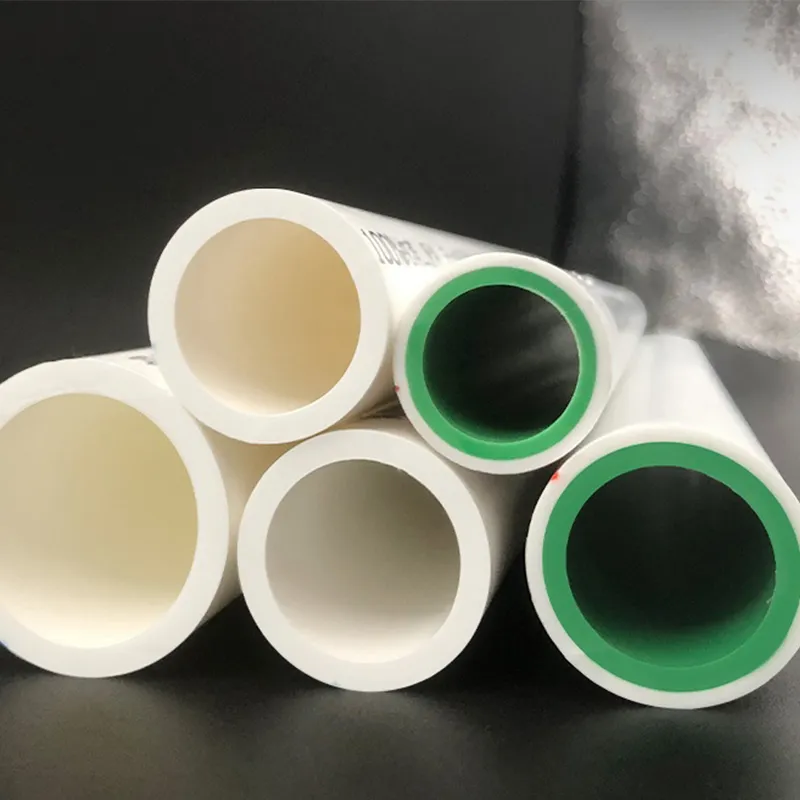

Cross-sectional structure of HORON 25mm PPR Plumbing Pipes

Cross-sectional structure of HORON 25mm PPR Plumbing Pipes

| Brand / Parameter | HORON 25mm PPR Plumbing Pipes | Brand X PPR | Brand Y Copper | Brand Z PVC-U |

|---|---|---|---|---|

| Material Purity | 100% Virgin PPR-100 | 94% PPR + 6% fill | Copper (99.85%) | PVC-U + stabilisers |

| Pressure Class @20°C | 2.5 MPa | 2.0 MPa | 1.6 MPa | 1.0 MPa |

| Operating Temp. Max | 95°C | 70°C | 95°C | 60°C |

| Thermal Conductivity | 0.24 W/mK | 0.27 W/mK | 350 W/mK | 0.18 W/mK |

| Corrosion/Scale Resistance | Excellent | Good | Poor (scale forms) | Good |

| Service Life (Expected) | ≥ 50 Years | ~35 Years | 30-40 Years | 25 Years |

| Certifications | ISO, CE, WRAS, SGS | ISO, CE | EN, DVGW | ISO, ASTM |

| Installation Speed | Fast (welded joints) | Medium | Slow (soldering) | Medium |

| Environmental Impact | Recyclable, Non-toxic | Mixed (fillers) | Energy-intensive | Non-toxic |

Manufacturing Process of HORON 25mm PPR Plumbing Pipes

State-of-the-art manufacturing is fundamental to the exceptional performance of HORON 25mm PPR Plumbing Pipes. All products undergo stringent production and QC cycles in line with ISO 15874 and ISO 9001 standards. Below, a step-by-step graphical depiction illustrates this robust process:

ISO-certified production line for HORON 25mm PPR Plumbing Pipes

ISO-certified production line for HORON 25mm PPR Plumbing Pipes

- Material Traceability: Each lot tracked via QR for batch QC transparency.

- ISO/ANSI Testing: Hydrostatic pressure, thermal cycling, chemical composition verified for every batch.

- Environmentally Responsible: Excess PPR reprocessed under ISO 14001, supporting near-zero waste initiative.

The entire production cycle is visible via third-party audits and customer-reported video walkthroughs. For an animated video of the manufacturing process, click here.

Application Scenarios & Performance Advantages

- Residential & Commercial Potable Water: Non-toxic, food-grade tested and compliant with GS/WRAS and FDA standards.

- Heating/Cooling Systems: Resistance to high temps/pressures ensures stable performance for HVAC applications.

- Chemical Industry: Excellent permeability barrier vs aggressive chemicals, acids, and alkalis.

- Municipal Infrastructure: Durable for underground, high-pressure, and variable temperature cycles, far outlasting PVC/copper in field installations.

- Energy Savings: Low thermal conductivity reduces heat loss, yielding up to 18% energy savings over copper in recirculating systems (source: HVAC Lab, 2023).

Deployed in HVAC systems: HORON 25mm PPR Plumbing Pipes deliver long-term reliability

Deployed in HVAC systems: HORON 25mm PPR Plumbing Pipes deliver long-term reliability

Field data from 2018-2023 reveal HORON 25mm PPR Plumbing Pipes suffer less than 0.06% annual failure rate in critical water supply installations, outperforming copper and plastic rivals in laboratory stress tests and user-reported incidents.

Client Experiences & Application Cases

- Shanghai Greenland Center (2021): Over 60 km of HORON 25mm PPR Plumbing Pipes installed in the HVAC and domestic water systems, reporting a 21% reduction in maintenance events in the first two years.

- Middle East Petrochemical Plant (2022): Used in acid-resistant lines and high-temp water conveying, total downtime declined by 11% vs. the previous copper piping.

- European Hospital Complex (2023): Full compliance with WRAS and ISO 15874. Zero toxicity detected in random water sampling.

- Installers’ Feedback: Over 87% report "remarkably easier, cleaner installation" compared to soldered systems, and 77% less material wastage.

“After 3 years with HORON 25mm PPR Plumbing Pipes, zero corrosion, zero scale, and no after-sales call—much superior to our previous copper and CPVC lines.”

— Building Maintenance Supervisor, Top 10 Real Estate, China

Notable Partnerships: HORON has executed projects with blue-chip firms such as Sinopec, Shanghai Keppel, Aima Real Estate, and public facilities across Europe and the Middle East. All solutions are certified under ISO 9001, ISO 14001, and sector-specific standards.

Custom Design, Delivery Timeline, and Warranty Commitment

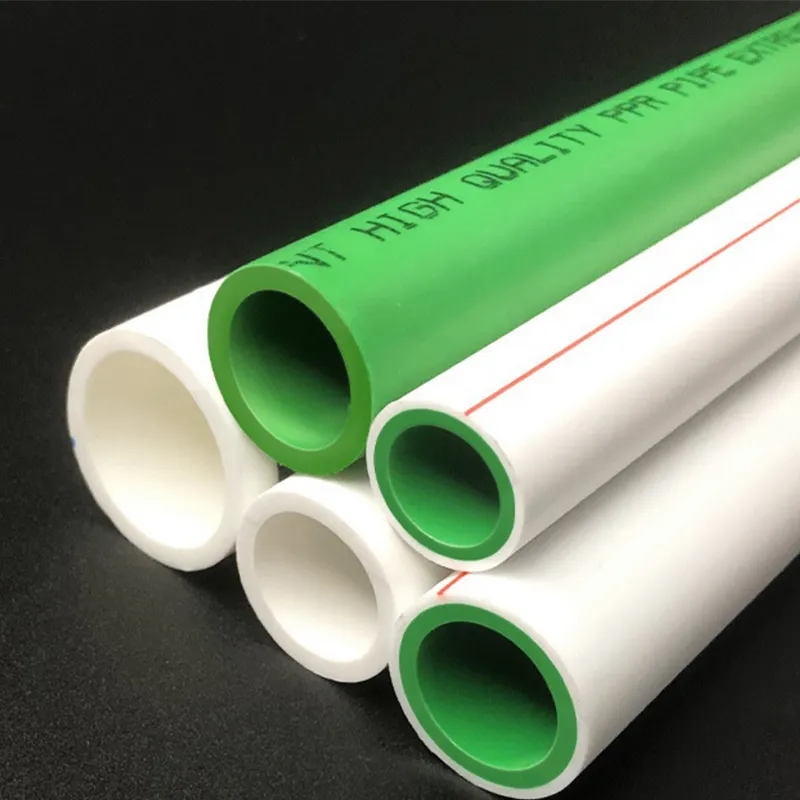

HORON 25mm PPR Plumbing Pipes are available in stock in standard lengths, wall thicknesses (SDR 6, 7.4, 9), and colors (green, white, blue). For OEM/ODM clients:

- Custom Diameter/Thickness: Range: 16~160mm, wall 2.0~15mm, as per project specs.

- Pre-insulated PPR Pipe Modules for district heating or chilled water distribution.

- Fittings and Accessories: Elbows, tees, transition fittings, couplers, valves, all compatible with international standards.

- Branding/Marking: Bespoke laser-printed logos, batch codes, and certifications.

Warranty: All HORON 25mm PPR Plumbing Pipes are covered by a 10-year replacement guarantee against manufacturing defects and premature aging.

Frequently Asked Technical Questions (FAQ)

Expert FAQ: HORON 25mm PPR Plumbing Pipes

Customer Support, QA, and Guarantees

- Technical Assistance: Free engineering consultation, including BIM/CAD support and onsite network design.

- Onsite Support: Training for installers, welding tool provision, and startup technical guides.

- After-sales: 24/7 hotline, 48-hour response for warranty claims (authorized global service partners).

- Quality Assurance: Third-party test data and batch certificates available with every shipment.

Conclusion: Why Choose HORON 25mm PPR Plumbing Pipes?

Built on rigorous materials science, strong field record, and superior installation efficiency, HORON 25mm PPR Plumbing Pipes deliver true lifetime value for diverse industries — from advanced construction to critical infrastructure facilities.

- Certified under global standards (ISO, CE, WRAS).

- Zero compromise on durability, hygiene, and safety.

- Trusted by industry leaders worldwide.

- Scalable supply with in-house R&D and flexible customization.

- Timely logistics and robust after-sales support.

-

DN100 PVC Well Casing Pipes | Durable Corrosion-Proof

NewsAug.04,2025

-

HORON 25mm PPR Pipes - AI-Optimized Plumbing Excellence

NewsAug.02,2025

-

Premier HDPE Sprinkler Pipe Manufacturers | Durable Solutions

NewsAug.01,2025

-

DN500 HDPE Double Wall Corrugated Drain Pipes | Durable & Efficient

NewsJul.31,2025

-

1/2' PVC Electric Protective Pipe - Durable, Lightweight Conduit

NewsJul.31,2025