Oct . 02, 2024 16:23 Back to list

type of ppr pipe factory

PPR (Polypropylene Random Copolymer) pipes have gained significant popularity in the construction and plumbing industry due to their durability, corrosion resistance, and energy efficiency. A type of thermoplastic piping, PPR is widely used in various applications, including hot and cold water supply, heating systems, and even in industrial processes. The rising demand for these pipes has led to the establishment of numerous PPR pipe factories worldwide, contributing to the economy and enhancing the quality of infrastructure.

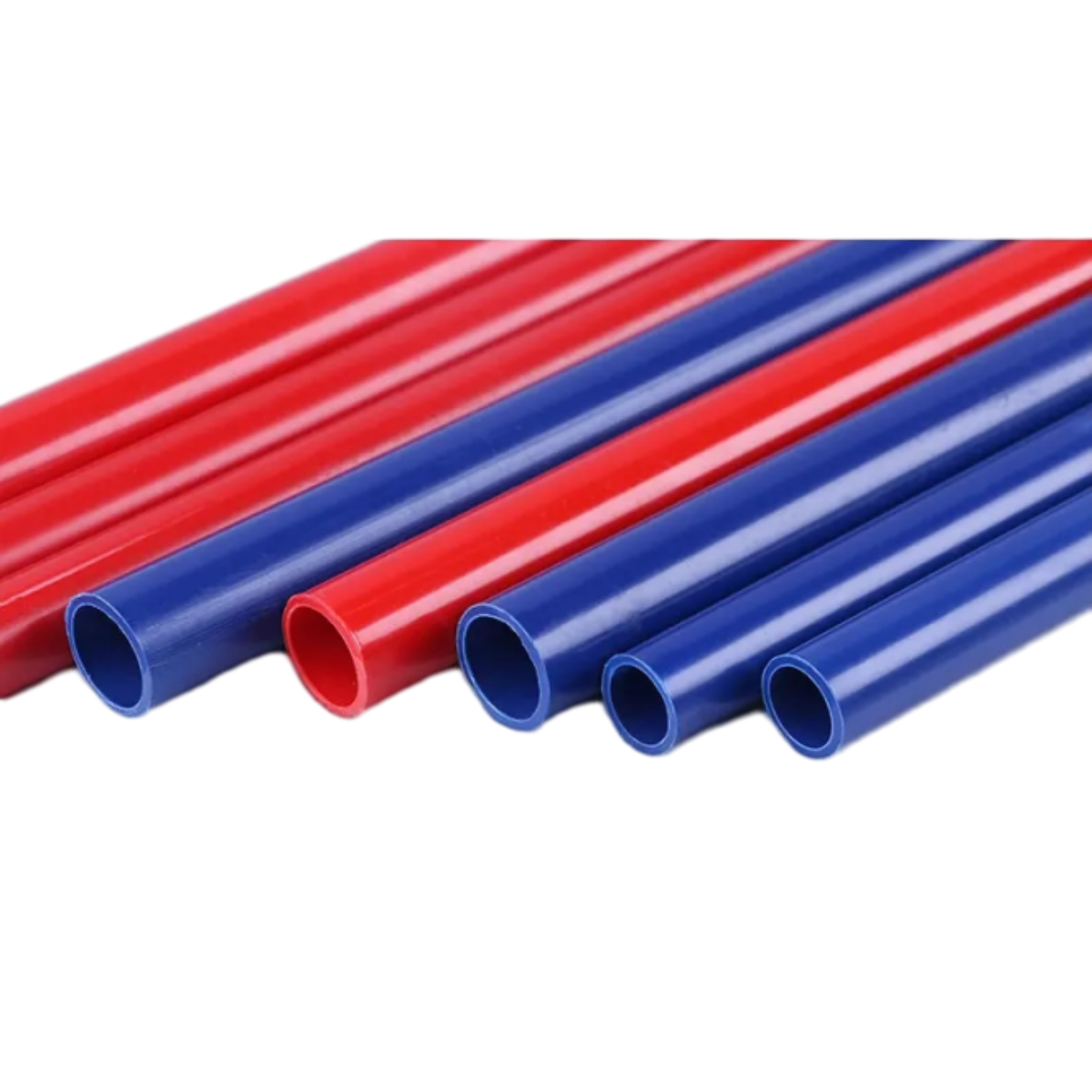

A typical PPR pipe factory is equipped with advanced machinery to ensure high-quality production standards. The manufacturing process usually starts with the selection of raw materials, which includes polypropylene resin, additives for stabilization, and colorant to differentiate pipe types. The quality of these raw materials is crucial, as it directly affects the properties and performance of the final product.

.

In addition to standard pipes, many factories also produce a variety of fittings, such as elbows, tees, and joints, which are essential for the installation of piping systems. These fittings can also be manufactured using the same PPR material, ensuring compatibility and seamless integration within a plumbing system.

type of ppr pipe factory

One of the main advantages of PPR pipes produced in a factory setting is their exceptional resistance to high temperatures and pressures. This makes them ideal for transporting hot water and steam, making them a popular choice for residential and commercial heating systems. Furthermore, PPR pipes are lightweight and easy to install, reducing labor costs and time during installation.

Another significant advantage of PPR pipes is their environmentally friendly nature. PPR materials are recyclable, and the manufacturing process typically produces fewer emissions compared to traditional materials like metal or PVC. Many factories are now implementing sustainable practices, further minimizing their ecological footprint.

In conclusion, PPR pipe factories play a vital role in producing high-quality piping solutions that cater to various applications. The advancements in technology and manufacturing processes have led to the development of products that are not only reliable but also environmentally friendly. As the construction and plumbing industries continue to evolve, the demand for PPR pipes will likely grow, solidifying their place as a preferred material for modern infrastructure.

-

DN100 PVC Well Casing Pipes | Durable Corrosion-Proof

NewsAug.04,2025

-

HORON 25mm PPR Plumbing Pipes - AI-Enhanced & Reliable

NewsAug.03,2025

-

HORON 25mm PPR Pipes - AI-Optimized Plumbing Excellence

NewsAug.02,2025

-

Premier HDPE Sprinkler Pipe Manufacturers | Durable Solutions

NewsAug.01,2025

-

DN500 HDPE Double Wall Corrugated Drain Pipes | Durable & Efficient

NewsJul.31,2025

-

1/2' PVC Electric Protective Pipe - Durable, Lightweight Conduit

NewsJul.31,2025