Nov . 22, 2024 05:26 Back to list

ppr pipe 1 price factories

The Dynamics of PPR Pipe Prices from Manufacturing Perspectives

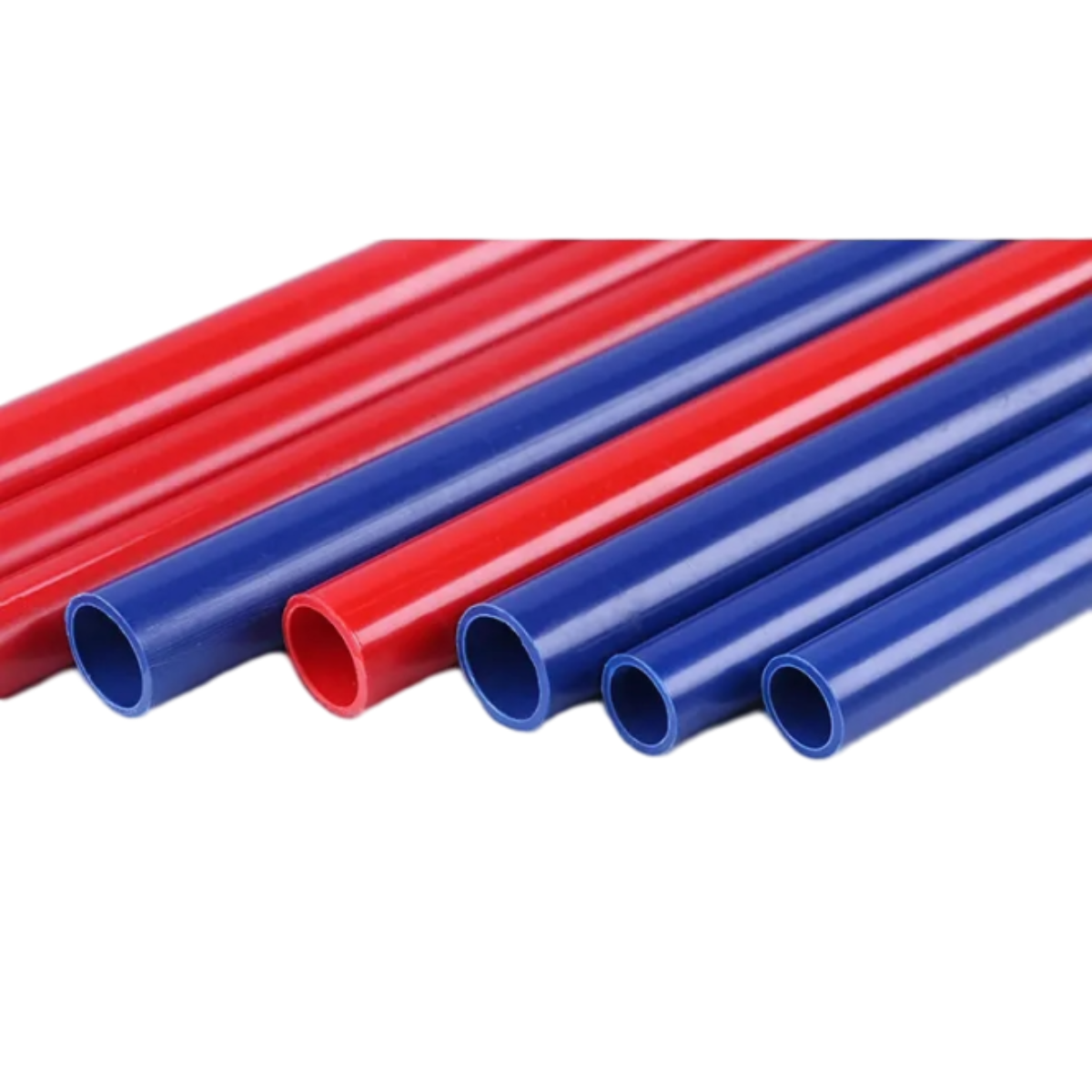

Polypropylene Random Copolymer (PPR) pipes have emerged as a popular choice in plumbing and construction industries due to their durability, resistance to corrosion, and ease of installation. As the demand for PPR pipes continues to soar, understanding the pricing dynamics from manufacturing factories is crucial for both suppliers and consumers.

Understanding PPR Pipes

PPR pipes are made from a combination of polypropylene and random ethylene, allowing them to withstand high temperatures and pressures. These pipes are widely used for both hot and cold water distribution systems, making them a versatile option for residential and commercial applications. They offer several advantages over traditional materials like PVC or metal, including lightweight properties, lower maintenance costs, and a longer lifespan.

Factors Influencing PPR Pipe Prices

1. Raw Material Costs The primary factor influencing the price of PPR pipes is the cost of raw materials. Polypropylene resin prices fluctuate based on global oil prices and supply chain dynamics. Any increase in oil prices directly impacts manufacturing costs, which in turn affects market prices.

2. Manufacturing Processes Different factories may employ various manufacturing techniques, which can lead to price variations. Factories that utilize advanced technologies and automated systems may achieve economies of scale, permitting competitive pricing compared to those using traditional methods.

3. Labor Costs Labor expenses across different regions play a significant role in determining final prices. In countries where labor is more affordable, production costs for PPR pipes are generally lower, allowing factories to offer more competitive pricing.

ppr pipe 1 price factories

4. Market Demand and Supply The balance between supply and demand significantly affects pricing. During peak construction seasons, demand surges, often leading to price hikes. Conversely, during downtimes, manufacturers may lower prices to stimulate sales.

5. Quality and Certification The quality of PPR pipes and their compliance with international standards can also influence prices. Pipes that meet stringent quality and safety certifications typically command higher prices, providing assurance of reliability and performance.

Regional Price Variations

PPR pipe prices can vary significantly by region. In developing countries, where infrastructure projects are booming, the demand is high but competition among manufacturers can lead to lower prices. Conversely, in developed countries, where quality and compliance with regulations are prioritized, prices tend to be higher.

Future Trends

As awareness of green building practices grows, the demand for environmentally friendly materials such as PPR will likely continue to rise. This shift is expected to further shape pricing strategies. Additionally, with advancements in production technologies and the increasing adoption of sustainable practices, manufacturers may find innovative ways to balance costs while ensuring quality.

Conclusion

In summary, the price of PPR pipes from manufacturing factories is influenced by a complex interplay of raw material costs, manufacturing techniques, labor expenses, market demand, and quality considerations. Understanding these factors is vital for stakeholders within the industry, enabling strategically informed decisions whether for procurement or investment. As the market continues to evolve, staying updated on these dynamics will be essential for both manufacturers and consumers alike.

-

Durable DN500 HDPE Double Wall Corrugated Drain Pipes

NewsAug.06,2025

-

32mm HDPE Pipes Coil: Durable & Flexible Water Supply

NewsAug.05,2025

-

DN100 PVC Well Casing Pipes | Durable Corrosion-Proof

NewsAug.04,2025

-

HORON 25mm PPR Plumbing Pipes - AI-Enhanced & Reliable

NewsAug.03,2025

-

HORON 25mm PPR Pipes - AI-Optimized Plumbing Excellence

NewsAug.02,2025

-

Premier HDPE Sprinkler Pipe Manufacturers | Durable Solutions

NewsAug.01,2025