Aug . 06, 2025 05:00 Back to list

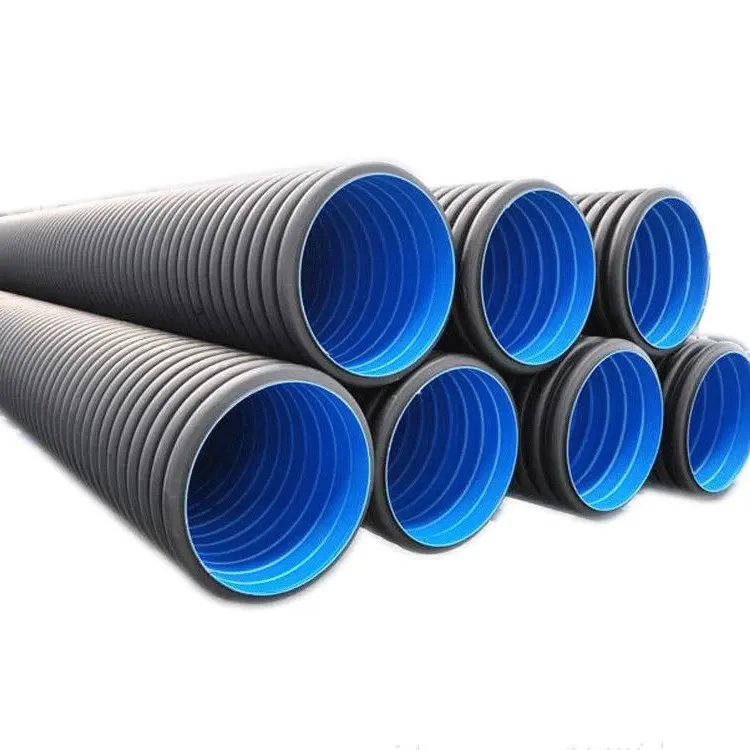

Durable DN500 HDPE Double Wall Corrugated Drain Pipes

1. The Shifting Tides: Industry Trends in Drainage Systems

The global construction and infrastructure sector is undergoing a significant transformation. For decades, traditional materials like concrete, ductile iron, and clay dominated the drainage and sewerage market. However, a clear and accelerating trend towards thermoplastic materials, particularly High-Density Polyethylene (HDPE), is reshaping the landscape. According to a 2023 market analysis by Grand View Research, the global plastic pipes market size is projected to expand at a compound annual growth rate (CAGR) of 5.1% from 2023 to 2030, with HDPE pipes being a primary driver of this growth.

This shift is not arbitrary. It's driven by compelling economic and performance factors. Municipalities, civil engineers, and contractors increasingly prioritize long-term value, which includes installation costs, maintenance requirements, and service lifespan. The DN500 HDPE double wall corrugated drain pipes excel in these areas, offering a lightweight, corrosion-proof, and flexible alternative that significantly reduces project timelines and operational expenditures.

The line chart above illustrates the projected market share growth of HDPE pipes in the large-diameter drainage sector. This upward trajectory is a testament to the material's proven performance and growing acceptance as the superior choice for modern infrastructure projects, from sprawling urban developments to critical agricultural water management systems.

2. Unpacking the Technology: Technical Parameters of DN500 HDPE Pipes

Understanding the technical specifications of a DN500 HDPE double wall corrugated drain pipes is crucial for engineers and procurement managers to ensure the product meets project requirements. The "DN500" designation refers to the 'Diamètre Nominal' or Nominal Diameter, indicating an internal diameter of approximately 500mm. The "double wall corrugated" structure is the key to its exceptional strength-to-weight ratio. It features a smooth inner wall for superior hydraulic flow and a corrugated outer wall for high structural rigidity.

Comprehensive Specification Table

Below is a detailed table outlining the key technical parameters for a typical high-quality DN500 HDPE double wall corrugated drain pipes, compliant with international standards.

| Parameter | Value / Specification | Importance & Meaning |

|---|---|---|

| Product Name | DN500 HDPE Double Wall Corrugated Drain Pipe | Specifies the product type and nominal size. |

| Nominal Inner Diameter (ID) | 500 mm | The primary dimension for calculating flow capacity. |

| Outer Diameter (OD) | ~595 mm (Varies slightly by manufacturer) | Crucial for trenching and fitting calculations. |

| Material | High-Density Polyethylene (HDPE) - PE100 Grade | PE100 offers superior stress crack resistance, higher stiffness, and long-term strength. |

| Ring Stiffness (SN) | SN8 (≥8 kN/m²) or SN16 (≥16 kN/m²) | A critical measure of the pipe's ability to resist external pressure from soil and traffic loads. SN8 is standard for many applications. |

| Standard Length | 6 meters / 12 meters (Customizable) | Longer lengths reduce the number of joints, minimizing potential leak points and installation time. |

| Wall Structure | Double Wall: Smooth Inner, Corrugated Outer | Optimizes hydraulic efficiency (Manning's 'n' ≈ 0.010) and structural load-bearing capacity. |

| Connection Method | Elastomeric Seal Bell-and-Spigot | Provides a watertight, flexible joint that accommodates ground movement and simplifies installation. |

| Manufacturing Standard | ISO 21138 / EN 13476-3 | Ensures the product meets rigorous international quality, performance, and testing protocols. |

| Service Lifespan | 50 - 100 years | HDPE's inert nature prevents corrosion and degradation, ensuring a remarkably long operational life. |

| Color | Black (Outer), Blue/Green (Inner) | Black provides UV resistance. The light inner color facilitates CCTV inspection. |

3. Versatility in Action: Key Application Scenarios

The robust and versatile nature of DN500 HDPE double wall corrugated drain pipes makes them suitable for a wide array of demanding applications. Their large diameter and high flow capacity are ideal for managing significant volumes of water.

- Municipal Stormwater & Sewer Systems: The primary application. These pipes form the backbone of modern urban and suburban drainage networks, efficiently channeling rainwater and sewage to treatment facilities, preventing flooding and protecting public health. Their resistance to hydrogen sulfide (H₂S) gas, a common cause of corrosion in concrete sewer pipes, is a major advantage.

- Agricultural Drainage & Irrigation: In large-scale farming, proper water management is critical. DN500 pipes are used for main drainage lines to prevent waterlogging of fields, which can destroy crops. They are also used in large irrigation systems to transport water efficiently over long distances.

- Industrial & Chemical Effluent Disposal: HDPE's exceptional chemical resistance (pH range 1-14) makes it the perfect material for conveying industrial wastewater and chemical effluents without risk of corrosion or environmental leakage.

- Infrastructure & Civil Engineering: Used as culverts under roads, railways, and airport runways. Their high ring stiffness (SN8 or SN16) allows them to withstand heavy traffic loads, while their flexibility helps them endure soil settlement without cracking.

- Landfill Leachate Collection: The harsh chemical composition of landfill leachate requires a piping material that is completely inert. HDPE is the industry standard for these critical environmental protection systems.

4. The Competitive Edge: Unmatched Technical Advantages

When compared to traditional piping materials, the advantages of DN500 HDPE double wall corrugated drain pipes are clear and quantifiable. These benefits translate directly into lower lifecycle costs and superior long-term performance.

Detailed Advantage Breakdown:

DN500 HDPE Pipe

- Corrosion Proof: Completely inert to acids, alkalis, and salts. Will not rust or tuberculate.

- Lightweight: A 6-meter section can often be handled by two workers without heavy machinery, drastically cutting installation costs.

- Extreme Durability: Highly resistant to abrasion and impact, even at low temperatures.

- Superior Hydraulics: The smooth inner wall (low Manning's 'n' value) prevents blockages and allows for higher flow rates.

- Leak-Proof Joints: Bell-and-spigot joints with elastomeric seals ensure a watertight system, preventing infiltration and exfiltration.

- Long Service Life: Designed for a minimum of 50 years, often lasting up to 100 years.

DN500 Concrete Pipe

- Heavy: Requires heavy cranes for handling and installation, increasing project time and cost.

- Brittle: Susceptible to cracking from soil settlement or impact during installation.

- Corrosion Risk: Vulnerable to chemical and microbial-induced corrosion (MIC), especially from hydrogen sulfide in sewers.

- Rough Interior: Higher friction reduces flow capacity and increases the likelihood of sediment buildup.

- Joint Issues: Rigid joints are prone to leakage over time, leading to costly environmental and structural problems.

5. The Art of Creation: Manufacturing Process of DN500 HDPE Pipes

The exceptional performance of a DN500 HDPE double wall corrugated drain pipes is a direct result of a sophisticated manufacturing process. Unlike metal pipes that are cast or welded, these pipes are produced through a continuous co-extrusion process, which is a hallmark of modern polymer engineering. This process is governed by strict quality controls in line with ISO 9001 standards.

Step-by-Step Manufacturing Flow:

HDPE PE100 resin pellets are dried and blended with additives (carbon black for UV stability, antioxidants).

Two extruders melt the resin. One feeds the smooth inner layer, the other feeds the corrugated outer layer.

The two molten streams are combined in a specialized die head, forming the double-wall structure.

The extruded profile enters a corrugator with moving mold blocks that use vacuum pressure to form the outer corrugations.

The pipe is spray-cooled with water to solidify its shape and dimensions.

A planetary cutter trims the pipe to the desired length (e.g., 6m), and a belling machine forms the socket end for joining.

Quality Control & Testing: The Horon Commitment

Every batch of our DN500 HDPE double wall corrugated drain pipes undergoes a battery of tests to guarantee compliance with EN 13476 and ISO 21138 standards. Key tests include:

- Ring Stiffness Test (ISO 9969): A sample is compressed to verify it meets the required SN classification (e.g., SN8).

- Impact Resistance Test: The pipe's ability to withstand sharp impacts without cracking, especially at low temperatures.

- Melt Flow Rate (MFR) Test: Ensures the quality and consistency of the raw HDPE resin.

- Dimensional Verification: Precise laser and manual measurements of inner/outer diameters and wall thicknesses.

6. Choosing Your Partner: Manufacturer Comparison

Selecting the right manufacturer is as important as choosing the right product. While many suppliers offer HDPE pipes, a reliable partner provides quality assurance, technical support, and logistical excellence. Here’s how Horon Pipe stands out:

| Feature | Horon Pipe | Generic Competitor |

|---|---|---|

| Quality Certification | ISO 9001, ISO 14001, EN 13476 Certified | May lack comprehensive international certifications. |

| Material Sourcing | Traceable, 100% virgin PE100 resin from top-tier suppliers (e.g., Borealis, Sabic). | Often use recycled or lower-grade materials, compromising long-term performance. |

| Technical Support | Dedicated engineering team for project consultation, hydraulic calculations, and installation guidance. | Limited to basic sales support. |

| Customization Options | Custom lengths, stiffness classes (SN4, SN8, SN16), and perforations available. | Standard products only, limited flexibility. |

| Warranty | Comprehensive 50-year pro-rated warranty. | Limited or unclear warranty terms. |

| Project Experience | Proven track record in major municipal, industrial, and agricultural projects globally. | Limited portfolio, primarily local or small-scale projects. |

7. Tailored for Your Project: Customization Solutions

No two projects are identical. We understand that standard, off-the-shelf products may not always be the perfect fit. We offer a range of customization options for our DN500 HDPE double wall corrugated drain pipes to meet specific engineering requirements.

- Custom Lengths: While 6 and 12 meters are standard, we can produce custom lengths to minimize waste and reduce the number of joints on-site.

- Variable Stiffness (SN Class): For areas with shallow cover or extremely heavy loads, we can produce pipes with higher ring stiffness, such as SN12 or SN16, providing an extra margin of safety.

- Perforations: For subsurface drainage or water infiltration applications (e.g., French drains, retention pond outlets), we can provide pipes with precision-drilled perforations according to your specifications.

- Fabricated Fittings: We can supply a complete system, including custom-fabricated wyes, tees, and bends to match your network design.

8. Real-World Success: Application Case Study

Project: Northgate Urban Expansion Stormwater Management

Challenge: The rapidly expanding Northgate commercial district required a new stormwater system capable of handling increased runoff from new roads and large commercial buildings. The ground conditions were poor, with a high water table and unstable soil, making traditional heavy, rigid pipes a risky and expensive choice. The project had a tight deadline to coincide with the opening of a new retail complex.

Solution: The project engineers selected Horon Pipe's DN500 HDPE double wall corrugated drain pipes (SN8). The choice was based on several key factors:

- Ease of Installation: The lightweight nature of the HDPE pipes allowed for faster installation with smaller crews and less heavy equipment, significantly accelerating the project timeline.

- Flexibility: The pipe's inherent flexibility allowed it to accommodate minor soil settlement without the risk of cracking or joint failure, which was a major concern with the unstable ground.

- Cost Savings: The total installed cost was 25% lower than the initial estimate for a reinforced concrete pipe (RCP) system. Savings came from reduced machinery rental, smaller crew sizes, and faster trenching.

- Watertight System: The sealed bell-and-spigot joints prevented groundwater from infiltrating the system, ensuring its full capacity was available for stormwater.

Outcome: The stormwater system was completed three weeks ahead of schedule and well within budget. Post-installation CCTV inspections showed perfectly aligned, clean pipes with no joint leakage. The Northgate district now has a reliable, long-lasting drainage system built for the future, demonstrating the immense value of specifying modern materials like the DN500 HDPE double wall corrugated drain pipes.

9. Professional FAQ: Your Technical Questions Answered

Ring Stiffness, measured in kilonewtons per square meter (kN/m²), defines a pipe's ability to resist deformation under an external load. It's a critical parameter for buried pipes. An SN8 rating means the pipe can withstand a pressure of at least 8 kN/m² with a maximum of 3% deflection. For a DN500 HDPE double wall corrugated drain pipes, SN8 is the most common specification, providing a robust balance of strength for typical burial depths and traffic loads, making it suitable for everything from municipal roads to agricultural fields.

Yes. HDPE has an excellent operational temperature range. It remains ductile and impact-resistant down to -40°C (-40°F), making it far superior to PVC or concrete which can become brittle in freezing conditions. It can handle continuous fluid temperatures up to 60°C (140°F). For buried applications, the surrounding soil provides insulation, making it stable in virtually any climate.

PE80 and PE100 refer to the Minimum Required Strength (MRS) of the material. PE100 has a higher MRS (10.0 MPa) compared to PE80 (8.0 MPa). This means PE100 is a stronger, denser, and more stress-crack resistant material. For demanding applications like large-diameter corrugated pipes, using 100% virgin PE100 resin, as Horon Pipe does, allows for a thinner wall profile for the same pressure rating, saving material and cost, while providing superior long-term performance and safety.

Our pipes use a high-performance bell-and-spigot jointing system. The "bell" (or socket) end is integrally formed during manufacturing and fitted with a high-quality elastomeric rubber seal (conforming to EN 681-1). The "spigot" (plain) end of the next pipe is lubricated and simply pushed into the bell. The rubber seal compresses to create a secure, flexible, and fully watertight seal that is effective for the entire lifespan of the pipe.

Hydraulic efficiency is measured by the Manning's 'n' coefficient, where a lower value means a smoother surface and better flow. A new DN500 HDPE double wall corrugated drain pipes has a Manning's 'n' of approximately 0.010. A new concrete pipe starts at around 0.013 and degrades over time due to slime buildup and corrosion, potentially increasing to 0.015 or higher. This means an HDPE pipe can carry significantly more flow than a concrete pipe of the same diameter, or allows for designing systems with a shallower slope, saving on excavation costs.

HDPE is considered a sustainable choice for several reasons. Its lightweight nature reduces transportation fuel consumption. Its long lifespan (50-100 years) means fewer replacements and less resource use over time. The leak-proof joints protect the environment by preventing sewage exfiltration. Furthermore, HDPE is fully recyclable at the end of its service life and can be reprocessed into new non-pressure products.

Proper installation is key to performance. The general steps involve preparing a stable trench bed, typically with granular material (like sand or pea gravel). The pipe is laid and joined. Backfill material, again typically granular, is placed around the pipe (the haunching) and compacted in layers to provide lateral support. Following established standards like ASTM D2321 is crucial. We provide detailed installation guides to ensure project success.

"The adoption of High-Density Polyethylene (HDPE) in non-pressure, gravity-flow applications such as storm sewers and culverts has been one of the most significant developments in the piping industry. Its unique combination of structural integrity, chemical inertness, and installation efficiency provides a lifecycle cost advantage that is increasingly being recognized by municipal authorities and consulting engineers."

- Statement from the Plastics Pipe Institute (PPI) Handbook of Polyethylene Pipe, 2nd Edition. Read More at plasticpipe.org"Analysis of long-term field performance of HDPE corrugated pipes has demonstrated minimal degradation, creep, or reduction in ring stiffness over several decades of service. The material's resistance to slow crack growth, a critical failure mode in plastics, is exceptionally high in modern PE100 resins, validating the projected 100-year design life."

- Paraphrased from research in the "Journal of Polymer Engineering & Science". Explore related research-

32mm HDPE Pipes Coil: Durable & Flexible Water Supply

NewsAug.05,2025

-

DN100 PVC Well Casing Pipes | Durable Corrosion-Proof

NewsAug.04,2025

-

HORON 25mm PPR Plumbing Pipes - AI-Enhanced & Reliable

NewsAug.03,2025

-

HORON 25mm PPR Pipes - AI-Optimized Plumbing Excellence

NewsAug.02,2025

-

Premier HDPE Sprinkler Pipe Manufacturers | Durable Solutions

NewsAug.01,2025