Sep . 25, 2024 12:45 Back to list

HDPE Transition Coupling Manufacturing Solutions for Efficient Pipeline Connections

The Importance and Production of HDPE Transition Couplings

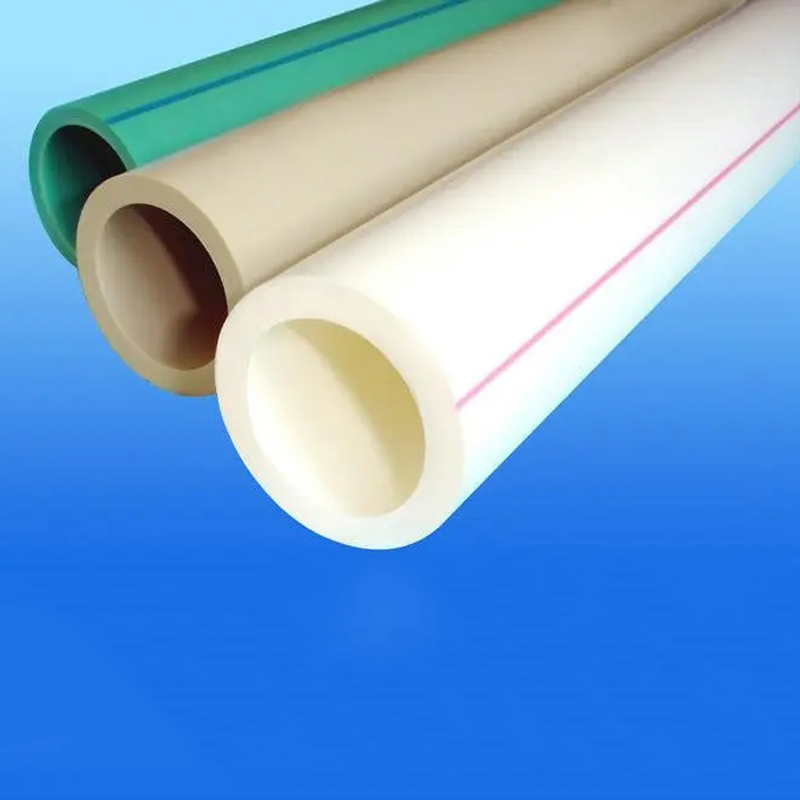

High-Density Polyethylene (HDPE) transition couplings are essential components in the plumbing and construction industries, known for their strength, durability, and resistance to various chemicals. As the global demand for efficient piping systems continues to grow, the focus on HDPE transition coupling factories has never been more significant.

HDPE, a versatile thermoplastic, is widely used for a variety of applications, including water supply, drainage, and gas distribution systems. Transition couplings serve as critical connectors that facilitate the joining of HDPE pipes to other types of materials, such as PVC, steel, or ductile iron. This adaptability is crucial in modern construction projects that often require integrating different piping materials.

The Importance and Production of HDPE Transition Couplings

Once the raw materials are secured, the production process involves several key steps. These include extrusion, molding, and testing. During extrusion, the HDPE is heated until it becomes pliable, allowing it to be shaped into various forms necessary for the couplings. Molding follows, where the extruded HDPE is formed into the final coupling shape under controlled conditions to achieve uniform density and strength.

hdpe transition coupling factory

Quality control is a critical aspect of the manufacturing process in HDPE transition coupling factories. Each batch of couplings undergoes rigorous testing to ensure that they meet the required specifications for pressure resistance, tensile strength, and dimensional accuracy. Only after passing these tests are the couplings deemed ready for distribution. This focus on quality ensures that end users receive reliable products that can withstand challenging environments.

Another crucial factor in the operation of HDPE transition coupling factories is sustainability. With the growing emphasis on environmental consciousness, many factories are adopting eco-friendly practices in their manufacturing processes. This includes recycling scrap material generated during production and minimizing energy consumption through efficient machinery and production techniques.

The demand for HDPE transition couplings is also driven by their long lifespan and low maintenance requirements. Compared to traditional materials, HDPE is less susceptible to corrosion, significantly reducing the costs associated with repairs and replacements. As urban infrastructure continues to evolve, the need for innovative solutions like transition couplings will persist, highlighting the role of factories in meeting this demand.

In conclusion, HDPE transition coupling factories play a pivotal role in the production of reliable and durable piping components. Through quality materials, advanced manufacturing processes, and a commitment to sustainability, these factories ensure that the growing needs of the plumbing and construction industries are met, paving the way for future advancements in pipeline technology. As the infrastructure landscape continues to change, the importance of high-quality transition couplings cannot be overstated.

-

32mm HDPE Pipes Coil: Durable & Flexible Water Supply

NewsAug.05,2025

-

DN100 PVC Well Casing Pipes | Durable Corrosion-Proof

NewsAug.04,2025

-

HORON 25mm PPR Plumbing Pipes - AI-Enhanced & Reliable

NewsAug.03,2025

-

HORON 25mm PPR Pipes - AI-Optimized Plumbing Excellence

NewsAug.02,2025

-

Premier HDPE Sprinkler Pipe Manufacturers | Durable Solutions

NewsAug.01,2025

-

DN500 HDPE Double Wall Corrugated Drain Pipes | Durable & Efficient

NewsJul.31,2025