Jan . 13, 2025 13:13 Back to list

hdpe sprinkler pipe manufacturers

Navigating the intricate landscape of submersible column pipe prices in China requires a blend of industry expertise, firsthand experience, and a deep understanding of the market dynamics. This article aims to equip buyers and industry professionals with the knowledge to make informed decisions concerning the procurement and utilization of submersible column pipes sourced from China.

Another pivotal factor influencing prices is the manufacturer's scale and capacity. Larger manufacturers often achieve economies of scale, allowing them to offer lower prices compared to smaller producers. However, this should not overshadow the importance of vetting the manufacturers' reputation for quality assurance and adherence to international standards, as this affects both the effectiveness and reliability of the pipes. When considering procurement strategies, it's advisable for buyers to engage directly with manufacturers rather than intermediaries to potentially reduce costs. Direct engagement often provides better insights into production timelines, quality control measures, and shipping logistics, fostering a more transparent and trustworthy transaction environment. Experts recommend conducting site visits or virtual tours of manufacturing facilities, if possible. This hands-on approach not only helps assess the operational capacity and production standards of the suppliers but also enhances trustworthiness. Testimonials and case studies from industry peers who have previously engaged with these manufacturers can further aid in validating the supplier's credibility. Lastly, proficiency with import regulations and logistical intricacies cannot be overstated. Import taxes, tariffs, and compliance with local standards can influence the final price buyers pay. Engaging with seasoned logistics partners specializing in Chinese imports ensures smoother transactions and helps avoid unexpected costs. Building a relationship with a reliable Chinese supplier extends beyond immediate price considerations; it encompasses establishing a partnership that supports sustained quality and service. Understanding these dynamics empowers buyers and industry professionals to effectively navigate the Chinese submersible column pipe market, ensuring that their investments yield high performance and durability.

Another pivotal factor influencing prices is the manufacturer's scale and capacity. Larger manufacturers often achieve economies of scale, allowing them to offer lower prices compared to smaller producers. However, this should not overshadow the importance of vetting the manufacturers' reputation for quality assurance and adherence to international standards, as this affects both the effectiveness and reliability of the pipes. When considering procurement strategies, it's advisable for buyers to engage directly with manufacturers rather than intermediaries to potentially reduce costs. Direct engagement often provides better insights into production timelines, quality control measures, and shipping logistics, fostering a more transparent and trustworthy transaction environment. Experts recommend conducting site visits or virtual tours of manufacturing facilities, if possible. This hands-on approach not only helps assess the operational capacity and production standards of the suppliers but also enhances trustworthiness. Testimonials and case studies from industry peers who have previously engaged with these manufacturers can further aid in validating the supplier's credibility. Lastly, proficiency with import regulations and logistical intricacies cannot be overstated. Import taxes, tariffs, and compliance with local standards can influence the final price buyers pay. Engaging with seasoned logistics partners specializing in Chinese imports ensures smoother transactions and helps avoid unexpected costs. Building a relationship with a reliable Chinese supplier extends beyond immediate price considerations; it encompasses establishing a partnership that supports sustained quality and service. Understanding these dynamics empowers buyers and industry professionals to effectively navigate the Chinese submersible column pipe market, ensuring that their investments yield high performance and durability.

Latest news

-

DN100 PVC Well Casing Pipes | Durable Corrosion-Proof

NewsAug.04,2025

-

HORON 25mm PPR Plumbing Pipes - AI-Enhanced & Reliable

NewsAug.03,2025

-

HORON 25mm PPR Pipes - AI-Optimized Plumbing Excellence

NewsAug.02,2025

-

Premier HDPE Sprinkler Pipe Manufacturers | Durable Solutions

NewsAug.01,2025

-

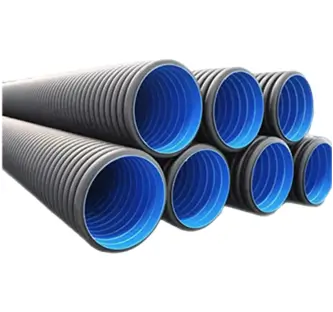

DN500 HDPE Double Wall Corrugated Drain Pipes | Durable & Efficient

NewsJul.31,2025

-

1/2' PVC Electric Protective Pipe - Durable, Lightweight Conduit

NewsJul.31,2025