Nov . 06, 2024 15:59 Back to list

hdpe pipe to pvc pipe connection factories

Connection Solutions for HDPE and PVC Pipes An Overview

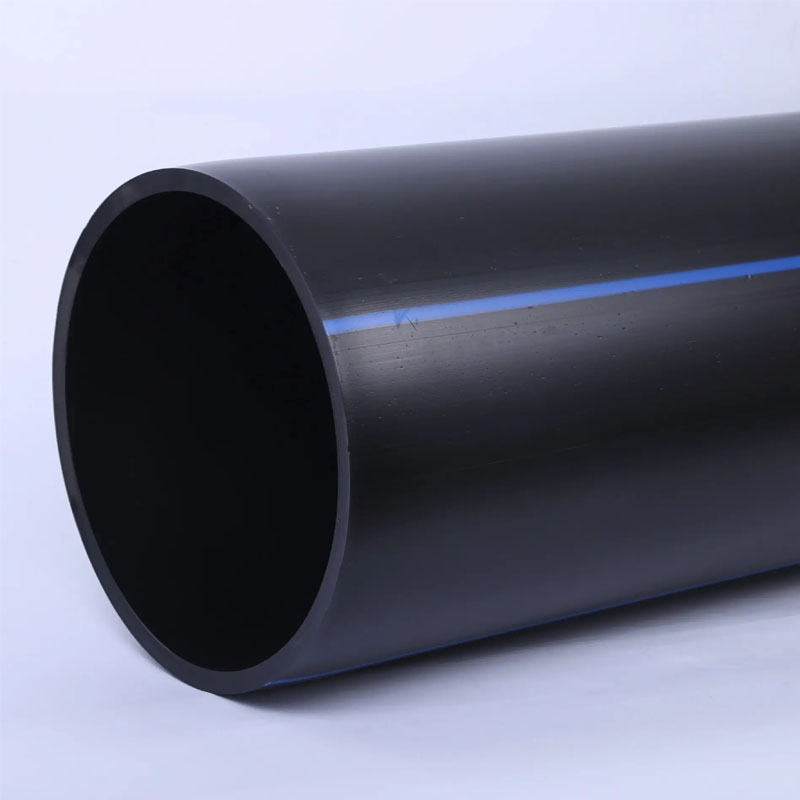

In the world of plumbing and construction, the connection of different types of pipes is a crucial aspect that impacts the overall performance and durability of a system. High-Density Polyethylene (HDPE) and Polyvinyl Chloride (PVC) are two of the most commonly used pipe materials in various applications, including water supply, drainage, and irrigation. However, connecting these two different pipe types poses a challenge that requires innovative solutions.

HDPE pipes are renowned for their flexibility, resistance to corrosion, and ability to withstand high pressure and extreme temperatures. They are often used in applications where movement in the ground is expected, such as in areas prone to earthquakes. On the other hand, PVC pipes are rigid and have excellent chemical resistance, making them suitable for a variety of plumbing applications where safety and sanitation are a priority.

Importance of Proper Connections

The junction between HDPE and PVC pipes must be executed with precision to prevent leaks and ensure a seamless flow of liquid. A poorly executed connection can lead to leaks, water loss, and even damage to surrounding infrastructure. Therefore, understanding the methods and products available for connecting these two materials is critical for contractors and engineers.

Connection Methods

1. Mechanical Couplings These are among the most common methods for connecting HDPE and PVC pipes. Mechanical couplings come in various designs, including bell-and-spigot systems and flange connections, providing a strong and reliable junction. They allow for movement and flexibility, which is vital in applications where ground movement may occur.

hdpe pipe to pvc pipe connection factories

2. Transition Fittings Transition fittings are specially designed to connect HDPE and PVC pipes directly. These fittings are available in various sizes and configurations, ensuring compatibility with standard pipe diameters. They are specifically engineered to handle the unique characteristics of both materials, ensuring a secure and effective connection.

3. Adhesives and Sealants In some cases, adhesives specifically designed for plastic pipe bonding can be used, although this method is less common due to the differing properties of HDPE and PVC. It is crucial to select the right type of adhesive that can accommodate both materials' thermal expansion characteristics.

Benefits of Professional Installation

Hiring professionals for the installation of HDPE to PVC pipe connections ensures that the proper techniques and materials are employed. Trained contractors understand the nuances involved in working with different materials and can provide expert guidance on the best practices for installation, minimizing the risk of future problems.

Conclusion

The collaboration between HDPE and PVC pipes is a vital component of many plumbing and construction projects. With a variety of connection methods available—from mechanical couplings to transition fittings—professionals in the field can ensure that these materials work in harmony. By understanding the unique properties of both types of pipe and the options for connecting them, stakeholders can contribute to sustainable and effective infrastructure that stands the test of time.

-

Durable DN500 HDPE Double Wall Corrugated Drain Pipes

NewsAug.06,2025

-

32mm HDPE Pipes Coil: Durable & Flexible Water Supply

NewsAug.05,2025

-

DN100 PVC Well Casing Pipes | Durable Corrosion-Proof

NewsAug.04,2025

-

HORON 25mm PPR Plumbing Pipes - AI-Enhanced & Reliable

NewsAug.03,2025

-

HORON 25mm PPR Pipes - AI-Optimized Plumbing Excellence

NewsAug.02,2025

-

Premier HDPE Sprinkler Pipe Manufacturers | Durable Solutions

NewsAug.01,2025