Jan . 19, 2025 03:30 Back to list

hdpe sprinkler pipe manufacturers

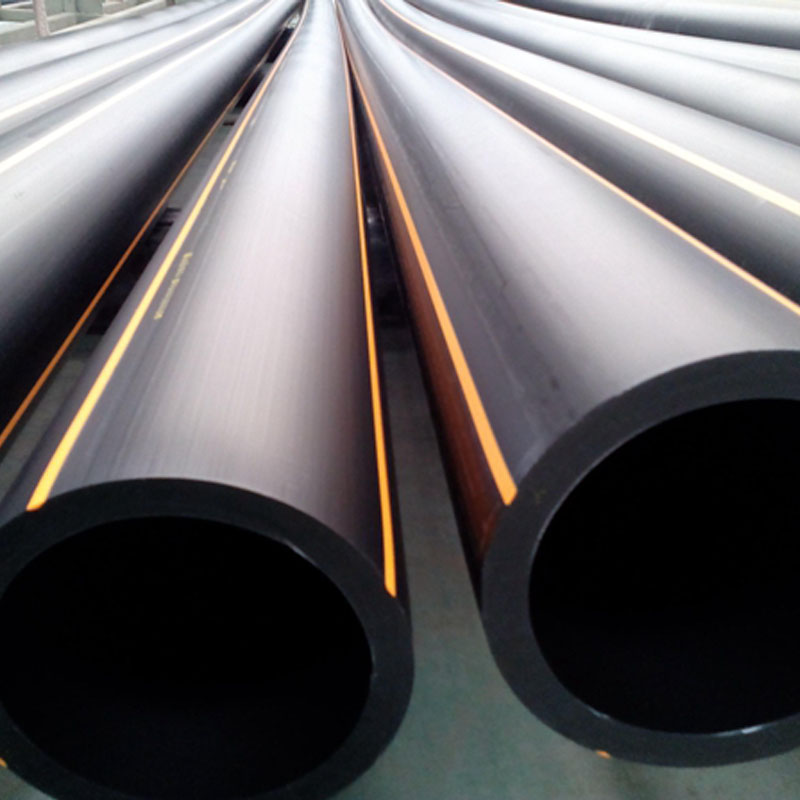

China's HDPE pipe joint couplers have garnered attention in the global market due to their robust features and unparalleled performance. As the construction and infrastructure sectors continue to evolve, the demand for reliable pipe systems is escalating. This has placed HDPE pipe joint couplers from China at the forefront, offering a unique blend of durability, flexibility, and environmental friendliness.

The environmental benefits also elevate the reputation of Chinese HDPE couplers. Given the global push towards sustainable construction and environmental stewardship, products that align with these goals are highly sought after. HDPE is fully recyclable, and its production process emits significantly lower levels of CO2 compared to traditional materials like metal or PVC. Trustworthiness is built on these green credentials, as project managers and environmentally conscious stakeholders increasingly prioritize eco-friendly options. Furthermore, Chinese manufacturers often offer comprehensive warranties and exemplary customer service, which reinforce the overall trust in the product. Feedback loops between customers and manufacturers are continuous, fostering a culture of continuous improvement and client satisfaction. This customer-centric approach not only enhances the product experience but also cements long-term partnerships and repeat business. Ultimately, when considering HDPE pipe joint couplers, stakeholders should assess the combined elements of experience, expertise, authoritativeness, and trustworthiness. Chinese manufacturers excel in these areas, providing solutions that are not only technically advanced but also reliable and environmentally sustainable. As global infrastructure needs evolve, the role of such high-quality, innovative couplers will be pivotal in ensuring efficient, long-lasting, and eco-friendly pipeline systems worldwide.

The environmental benefits also elevate the reputation of Chinese HDPE couplers. Given the global push towards sustainable construction and environmental stewardship, products that align with these goals are highly sought after. HDPE is fully recyclable, and its production process emits significantly lower levels of CO2 compared to traditional materials like metal or PVC. Trustworthiness is built on these green credentials, as project managers and environmentally conscious stakeholders increasingly prioritize eco-friendly options. Furthermore, Chinese manufacturers often offer comprehensive warranties and exemplary customer service, which reinforce the overall trust in the product. Feedback loops between customers and manufacturers are continuous, fostering a culture of continuous improvement and client satisfaction. This customer-centric approach not only enhances the product experience but also cements long-term partnerships and repeat business. Ultimately, when considering HDPE pipe joint couplers, stakeholders should assess the combined elements of experience, expertise, authoritativeness, and trustworthiness. Chinese manufacturers excel in these areas, providing solutions that are not only technically advanced but also reliable and environmentally sustainable. As global infrastructure needs evolve, the role of such high-quality, innovative couplers will be pivotal in ensuring efficient, long-lasting, and eco-friendly pipeline systems worldwide.

Latest news

-

DN100 PVC Well Casing Pipes | Durable Corrosion-Proof

NewsAug.04,2025

-

HORON 25mm PPR Plumbing Pipes - AI-Enhanced & Reliable

NewsAug.03,2025

-

HORON 25mm PPR Pipes - AI-Optimized Plumbing Excellence

NewsAug.02,2025

-

Premier HDPE Sprinkler Pipe Manufacturers | Durable Solutions

NewsAug.01,2025

-

DN500 HDPE Double Wall Corrugated Drain Pipes | Durable & Efficient

NewsJul.31,2025

-

1/2' PVC Electric Protective Pipe - Durable, Lightweight Conduit

NewsJul.31,2025