Sep . 09, 2024 21:34 Back to list

1 2 ppr pipe manufacturers

Understanding 1% 202% PPR Pipe Manufacturers A Comprehensive Overview

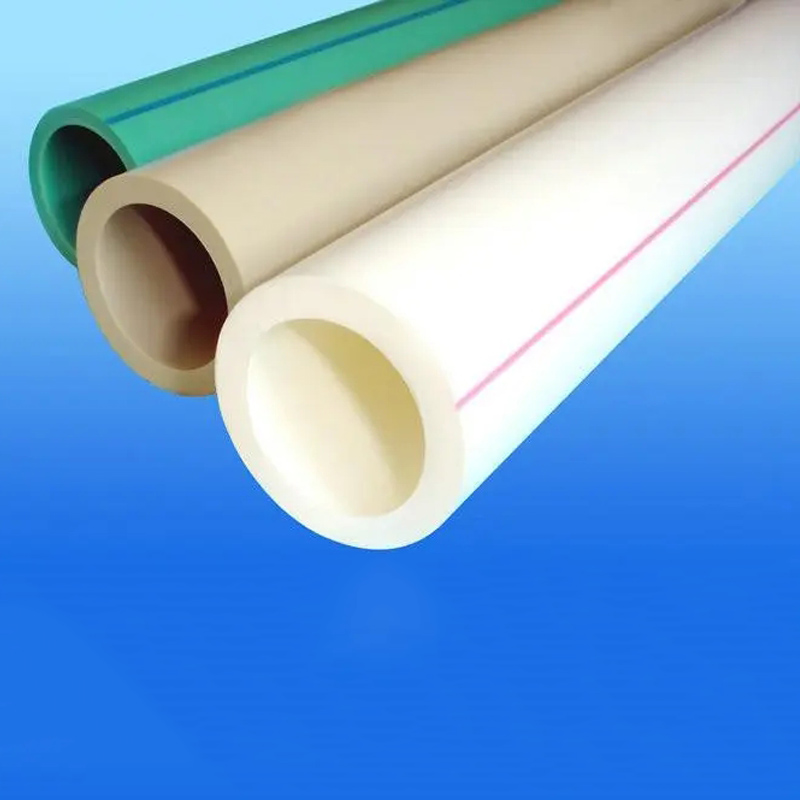

In the realm of plumbing and construction, the demand for reliable and efficient piping systems has been on the rise. Among the materials that have gained significant popularity are PPR pipes, known for their durability, resistance to corrosion, and cost-effectiveness. When discussing PPR pipes, it's essential to understand the specifications and how they relate to various applications, especially when we consider terms like 1% 202%.

Understanding 1% 202% PPR Pipe Manufacturers A Comprehensive Overview

PPR pipes come with various certifications and standards that manufacturers must adhere to. These guidelines ensure that the pipes can handle high pressures and temperatures without degrading, making them suitable for a wide range of uses, including potable water systems, irrigation, and HVAC applications. Manufacturers that focus on producing high-quality 1% 202% PPR pipes often invest in advanced technologies and rigorous testing processes to meet international standards.

1 2 ppr pipe manufacturers

The manufacturing process of PPR pipes typically involves the extrusion technique, where the raw polypropylene material is heated and forced through a die to create the desired pipe shape. This process allows for consistent quality and precision in dimensions, which is vital for effective installation and longevity. Quality manufacturers implement strict quality control measures throughout the production cycle, ensuring that every batch of pipes meets the expected performance metrics.

Another critical aspect to consider is the sustainability of PPR pipes. They are often favored for their environmental benefits compared to traditional metallic pipes. PPR pipes do not corrode, which reduces the risk of heavy metal leaching into water supplies, and they also have a lower carbon footprint during production. Many manufacturers focus on creating eco-friendly products, utilizing recyclable materials, and implementing energy-efficient manufacturing processes.

Choosing the right manufacturer is crucial for obtaining reliable PPR pipes. It is advisable to look for companies that have a proven track record in the industry, positive customer reviews, and certifications that authenticate their product quality. Reputable manufacturers often provide comprehensive warranties and after-sales support, which can be invaluable for long-term projects.

In conclusion, the world of 1% 202% PPR pipe manufacturing represents a commitment to quality, sustainability, and innovation. As the construction and plumbing industries continue to evolve, the significance of high-quality materials cannot be overstated. Understanding the specific standards and characteristics of PPR pipes will help consumers make informed decisions, ensuring that their projects are built on a foundation of reliability and efficiency. For those in the market for PPR piping solutions, delving into the offerings of recognized manufacturers can lead to better outcomes and enhanced satisfaction in their plumbing and construction endeavors.

-

32mm HDPE Pipes Coil: Durable & Flexible Water Supply

NewsAug.05,2025

-

DN100 PVC Well Casing Pipes | Durable Corrosion-Proof

NewsAug.04,2025

-

HORON 25mm PPR Plumbing Pipes - AI-Enhanced & Reliable

NewsAug.03,2025

-

HORON 25mm PPR Pipes - AI-Optimized Plumbing Excellence

NewsAug.02,2025

-

Premier HDPE Sprinkler Pipe Manufacturers | Durable Solutions

NewsAug.01,2025

-

DN500 HDPE Double Wall Corrugated Drain Pipes | Durable & Efficient

NewsJul.31,2025