Oct . 09, 2024 04:37 Back to list

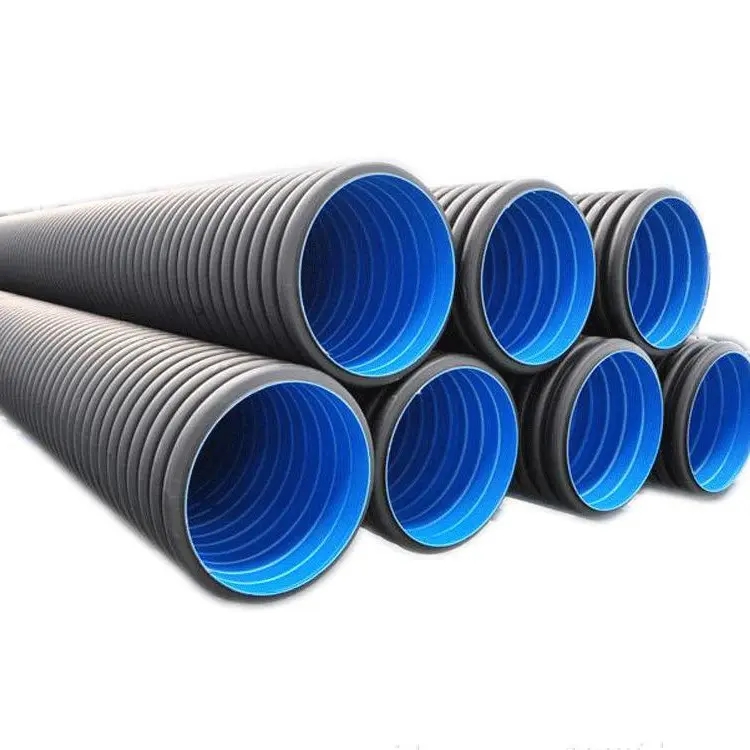

High-Density Polyethylene Conduit Coupling Manufacturer for Durable Electrical Solutions

The Importance of HDPE Conduit Couplings in Modern Infrastructure

High-density polyethylene (HDPE) conduit couplings are crucial components in the construction and maintenance of modern infrastructure. As societies increasingly rely on advanced communication and power systems, the demand for robust, reliable, and efficient conduit solutions continues to grow. This has led to the significant use of HDPE materials in various applications, particularly for enclosing and protecting electrical and telecommunications cables.

The Importance of HDPE Conduit Couplings in Modern Infrastructure

Firstly, HDPE is known for its exceptional durability and resistance to impact and corrosion. This resilience makes HDPE couplings suitable for both underground and above-ground installations, where they may be exposed to harsh environmental conditions. Unlike traditional materials, HDPE does not rust or degrade over time, ensuring a longer lifespan and reducing the need for frequent replacements.

hdpe conduit coupling factory

Secondly, the lightweight nature of HDPE makes installation more manageable and cost-effective. Contractors appreciate the ease with which HDPE conduits and couplings can be transported and assembled, minimizing labor costs and time on the job site. Additionally, the flexibility of HDPE allows for easy bending and fitting in various configurations, accommodating the specific needs of each project.

Moreover, HDPE couplings are environmentally friendly. The material is recyclable, and the manufacturing processes have a lower carbon footprint compared to traditional materials. This aligns with the modern trend towards sustainable construction practices, making HDPE conduits an attractive option for eco-conscious builders and developers.

In the context of factories producing HDPE conduit couplings, advanced manufacturing techniques are employed to ensure high quality and precision. Automation and quality control measures are crucial in maintaining the standards required for longevity and performance. Factories focus not only on the production efficiency but also on providing customized solutions to meet specific client requirements.

In conclusion, HDPE conduit couplings play a vital role in modern infrastructure by providing reliable protection for electrical and communication systems. Their durability, ease of installation, and environmental benefits make them indispensable in today’s fast-evolving technological landscape. As infrastructure continues to expand, so too will the reliance on HDPE solutions, underscoring the importance of factories dedicated to the production of these essential components.

-

DN100 PVC Pipes for Well Casings | Durable & Corrosion-Proof

NewsAug.07,2025

-

Durable DN500 HDPE Double Wall Corrugated Drain Pipes

NewsAug.06,2025

-

32mm HDPE Pipes Coil: Durable & Flexible Water Supply

NewsAug.05,2025

-

DN100 PVC Well Casing Pipes | Durable Corrosion-Proof

NewsAug.04,2025

-

HORON 25mm PPR Plumbing Pipes - AI-Enhanced & Reliable

NewsAug.03,2025

-

HORON 25mm PPR Pipes - AI-Optimized Plumbing Excellence

NewsAug.02,2025