Dec . 18, 2024 05:24 Back to list

Manufacturers of Double Wall Corrugated Drainage Pipes for Effective Water Management Solutions

Understanding Dual Wall Corrugated Drain Pipe Factories

Dual wall corrugated drain pipes have emerged as a vital component in modern drainage systems. Their design and functionality cater to various applications, from residential drainage to large-scale industrial uses. This article delves into the significance of dual wall corrugated drain pipe factories, highlighting their production processes, benefits, and the impact they have on infrastructure development.

What are Dual Wall Corrugated Drain Pipes?

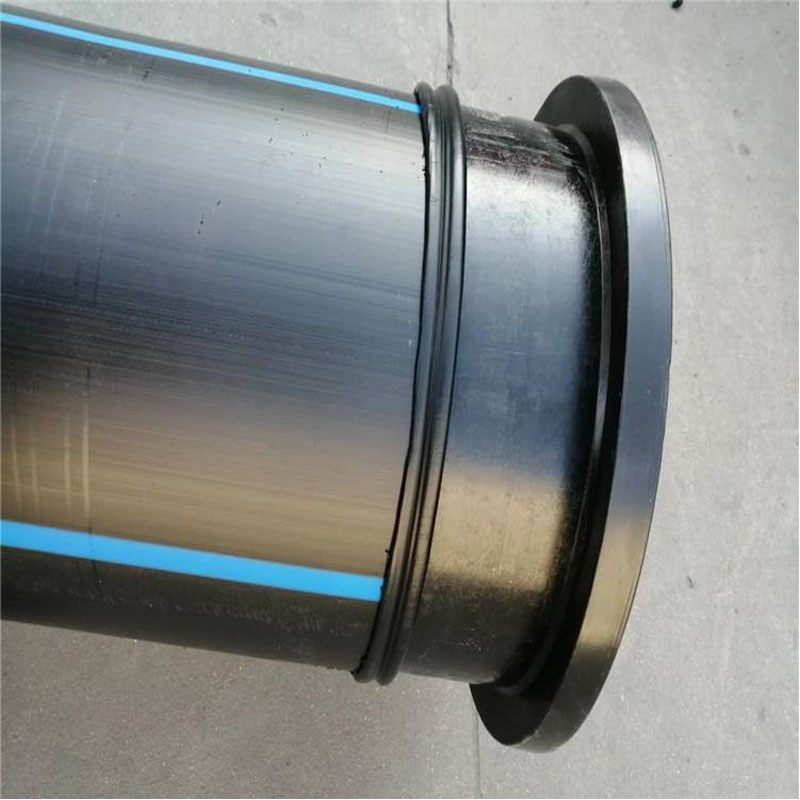

Dual wall corrugated drain pipes consist of two layers an inner smooth wall for optimal flow and an outer corrugated layer for structural strength. This unique design provides excellent hydraulic performance and durability, making them suitable for both gravity-fed and pressurized drainage systems. Commonly made from high-density polyethylene (HDPE) or other robust materials, these pipes are resistant to a wide range of chemicals, environmental stressors, and wear over time.

The Manufacturing Process

The production of dual wall corrugated drain pipes involves advanced manufacturing techniques. Factories employ extrusion processes where raw materials are heated and formed into the desired pipe shape. Here’s a step-by-step breakdown of how these pipes are manufactured

1. Material Selection High-density polyethylene or other polymers are chosen for their durability and resistance to corrosion.

2. Extrusion The raw materials are melted and extruded through a specially designed die that creates the inner smooth layer and the outer corrugated layer simultaneously.

3. Cooling and Sizing The extruded pipe is then cooled in a controlled environment, ensuring it retains its shape. Size and diameter are carefully measured during this stage.

4. Quality Control Factories implement rigorous quality checks to assess the pipes' structural integrity, flexibility, and flow characteristics. Testing ensures that the pipes meet industry standards and regulations.

dual wall corrugated drain pipe factories

5. Cutting and Packaging Finally, the pipes are cut to specific lengths and packaged for distribution. Care is taken during shipping to minimize damage and ensure the pipes reach their destination in optimal condition.

Advantages of Dual Wall Corrugated Drain Pipes

1. Durability The combination of materials and the design of dual wall pipes make them exceptionally durable. They can withstand harsh environmental conditions, including extreme temperatures and soil loads.

2. Hydraulic Efficiency The smooth inner wall promotes high flow rates, reducing the risk of blockages. This efficiency is crucial for maintaining effective drainage systems.

3. Easy Installation These pipes are lightweight compared to traditional materials, allowing for easier handling and quicker installation processes. They can be laid in various types of soil without the need for extensive excavation.

4. Cost-Effective Although the initial investment might be higher than traditional pipes, the long lifespan and reduced maintenance costs make dual wall corrugated pipes a cost-effective choice in the long run.

5. Environmental Impact Many manufacturers focus on sustainability by using recycled materials in their production processes. Additionally, the durability of these pipes also means fewer replacements, contributing to less waste.

The Impact on Infrastructure Development

With the increasing urbanization and the need for reliable drainage systems, the role of dual wall corrugated drain pipe factories is paramount. They contribute to the development of sustainable infrastructure, ensuring that urban areas can manage stormwater efficiently, mitigate flooding, and maintain clean water systems.

In conclusion, dual wall corrugated drain pipes are an engineering marvel that plays a critical role in modern drainage solutions. The factories producing these pipes are not just manufacturers; they are vital contributors to sustainable development and infrastructure resilience. As cities continue to grow and environmental challenges become more pronounced, the importance of such innovative products will only increase, ensuring that our drainage systems remain efficient and effective for years to come.

-

DN100 PVC Pipes for Well Casings | Durable & Corrosion-Proof

NewsAug.07,2025

-

Durable DN500 HDPE Double Wall Corrugated Drain Pipes

NewsAug.06,2025

-

32mm HDPE Pipes Coil: Durable & Flexible Water Supply

NewsAug.05,2025

-

DN100 PVC Well Casing Pipes | Durable Corrosion-Proof

NewsAug.04,2025

-

HORON 25mm PPR Plumbing Pipes - AI-Enhanced & Reliable

NewsAug.03,2025

-

HORON 25mm PPR Pipes - AI-Optimized Plumbing Excellence

NewsAug.02,2025