Jun . 26, 2024 08:03 Back to list

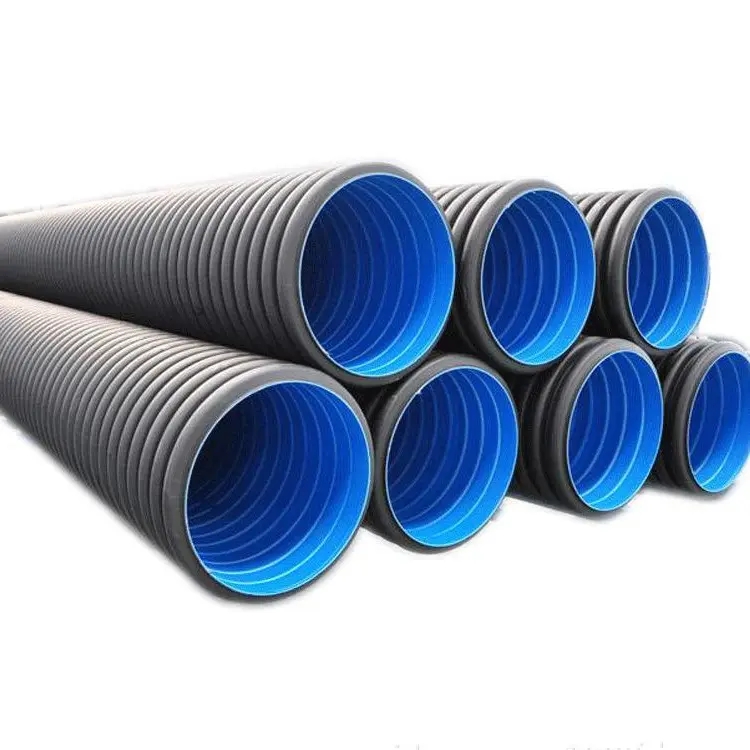

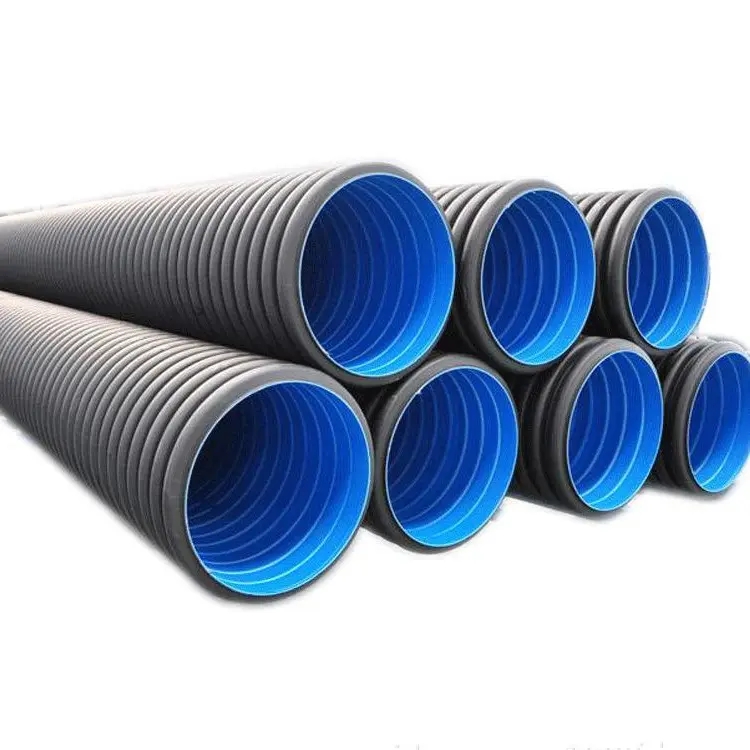

Top HDPE Corrugated Subsoil Drainage Pipe Manufacturers High Performance Solutions

Their lightweight nature makes them easy to handle and transport, reducing installation time and labor costs Their lightweight nature makes them easy to handle and transport, reducing installation time and labor costs

Their lightweight nature makes them easy to handle and transport, reducing installation time and labor costs Their lightweight nature makes them easy to handle and transport, reducing installation time and labor costs hdpe corrugated subsoil drainage pipe manufacturer. Moreover, the lack of joints or connections minimizes the risk of leaks, ensuring reliable performance over extended periods.

Environmental sustainability is another core focus for manufacturers. HDPE is a recyclable material, making it an eco-conscious choice. By using recycled content, manufacturers like XYZ Corporation contribute to reducing waste and minimizing the carbon footprint associated with pipe production. Additionally, the durability of HDPE ensures that these pipes last longer than traditional alternatives, further reducing the need for frequent replacements.

In conclusion, HDPE corrugated subsoil drainage pipes have transformed the landscape of water management, thanks to the expertise of manufacturers who continuously innovate and improve their products. Their combination of strength, versatility, and eco-friendliness has made them indispensable in agriculture, construction, and environmental remediation projects worldwide. As the demand for sustainable and efficient solutions continues to rise, manufacturers like XYZ Corporation will undoubtedly continue to lead the charge in this game-changing technology.

hdpe corrugated subsoil drainage pipe manufacturer. Moreover, the lack of joints or connections minimizes the risk of leaks, ensuring reliable performance over extended periods.

Environmental sustainability is another core focus for manufacturers. HDPE is a recyclable material, making it an eco-conscious choice. By using recycled content, manufacturers like XYZ Corporation contribute to reducing waste and minimizing the carbon footprint associated with pipe production. Additionally, the durability of HDPE ensures that these pipes last longer than traditional alternatives, further reducing the need for frequent replacements.

In conclusion, HDPE corrugated subsoil drainage pipes have transformed the landscape of water management, thanks to the expertise of manufacturers who continuously innovate and improve their products. Their combination of strength, versatility, and eco-friendliness has made them indispensable in agriculture, construction, and environmental remediation projects worldwide. As the demand for sustainable and efficient solutions continues to rise, manufacturers like XYZ Corporation will undoubtedly continue to lead the charge in this game-changing technology. -

HDPE Electrofusion Fittings Durable, Leak-Proof Conduit Solutions

NewsMay.31,2025

-

HDPE Compression Fittings Leak-Proof, Corrosion-Resistant Solutions

NewsMay.31,2025

-

Premium PP & HDPE Compression Fittings Leak-Proof & Durable Solutions

NewsMay.30,2025

-

HDPE Tee Fittings 48-Inch HDPE Pipe Solutions & Cost-Effective Services

NewsMay.30,2025

-

HDPE Compression Fittings Durable & Leak-Free Pipe Connectors

NewsMay.29,2025

-

HDPE Tee Fittings 48-Inch HDPE Pipe Cost & Factory Services

NewsMay.29,2025