May . 30, 2025 08:04 Back to list

HDPE Tee Fittings 48-Inch HDPE Pipe Solutions & Cost-Effective Services

- Overview of HDPE Tee in Pipeline Infrastructure

- Technical Advantages Over Traditional Materials

- Cost Analysis: 48-Inch HDPE Pipe Factories vs. Service Providers

- Customization for Industrial and Municipal Applications

- Case Study: Large-Scale HDPE Tee Implementations

- Quality Assurance and Compliance Standards

- Future Trends in HDPE Tee Manufacturing

(hdpe tee )

HDPE Tee: The Backbone of Modern Pipeline Systems

HDPE tee fittings are pivotal in ensuring leak-proof, durable connections within high-density polyethylene (HDPE) pipelines. With the global HDPE pipe market projected to grow at a CAGR of 5.2% through 2030, demand for robust components like 48-inch HDPE tees has surged. These fittings excel in industrial and municipal settings due to their corrosion resistance, flexibility, and longevity—outperforming PVC and steel alternatives by up to 50 years in lifespan.

Technical Superiority in Design and Performance

HDPE tees withstand pressures up to 500 PSI and temperatures ranging from -40°C to 80°C, making them ideal for extreme environments. Fusion welding ensures seamless joints, reducing failure risks by 92% compared to mechanical couplings. Additionally, their smooth inner surface minimizes turbulence, cutting energy costs by 15–20% in water distribution systems.

Factory vs. Service Provider: Cost Breakdown

| Vendor Type | Cost per Meter (USD) | Lead Time | Certifications |

|---|---|---|---|

| 48-Inch HDPE Pipe Factories | $180–$220 | 4–6 weeks | ISO 9001, ASTM F714 |

| Service Providers | $240–$300 | 2–3 weeks | AWWA C906, NSF/ANSI 61 |

Direct sourcing from factories cuts unit costs by 25%, but service providers offer faster turnaround and specialized certifications for potable water projects.

Tailored Solutions for Diverse Applications

Custom HDPE tees accommodate unique requirements, such as 48-inch diameters with SDR 11 or SDR 17 pressure ratings. For mining operations, abrasion-resistant carbon-black-infused HDPE reduces wear by 40%. Municipalities often opt for electrofusion tees with integrated IoT sensors to monitor pipeline integrity in real time.

Case Study: Urban Water Network Upgrade

In 2022, a U.S. city replaced 12 miles of aging steel pipes with HDPE tees and 48-inch HDPE lines. The project slashed maintenance expenses by $1.2 million annually and eliminated leaks within six months. Fusion-welded joints demonstrated zero failures under 200 PSI operational stress.

Compliance and Testing Protocols

Reputable manufacturers adhere to ASTM D3035 and EN 12201 standards. Third-party hydrostatic testing at 150% of rated pressure ensures durability. UV-stabilized HDPE tees maintain 98% tensile strength after 10,000 hours of accelerated weathering tests.

Why HDPE Tee Solutions Are Critical for 48-Inch Pipeline Networks

As infrastructure ages, HDPE tees offer a future-proof alternative with 50-year service guarantees. Their adaptability to trenchless installation methods reduces environmental disruption by 60%, while recyclability aligns with circular economy goals. Partnering with ISO-certified 48 inch HDPE pipe cost factories ensures scalability for megaprojects requiring 10,000+ fittings annually.

(hdpe tee )

FAQS on hdpe tee

Q: What are the key advantages of using an HDPE tee in piping systems?

A: HDPE tees offer high durability, corrosion resistance, and flexibility, making them ideal for high-pressure and underground applications. They ensure leak-free joints and are cost-effective for large-scale projects like 48-inch pipelines.

Q: What factors influence the cost of 48-inch HDPE pipe services?

A: Costs depend on material quality, pipe diameter (e.g., 48-inch), project scale, and logistics. Additional expenses may include installation labor, fittings like HDPE tees, and compliance with industry standards.

Q: How do factories determine pricing for 48-inch HDPE pipes?

A: Factories consider raw material costs, manufacturing complexity, and market demand. Bulk orders for 48-inch HDPE pipes with custom fittings like tees may qualify for volume discounts.

Q: What services are included in 48-inch HDPE pipe cost estimates from providers?

A: Providers typically cover material supply, HDPE tee integration, installation guidance, and quality testing. Some include transportation and post-installation support for large-diameter projects.

Q: Why choose HDPE tees for 48-inch pipe networks over traditional materials?

A: HDPE tees reduce long-term maintenance costs and resist chemical/abrasion damage. Their lightweight design simplifies handling in 48-inch systems, ensuring faster installation and lower labor expenses.

-

DN500 HDPE Double Wall Corrugated Drain Pipes for Efficient Drainage

NewsJul.23,2025

-

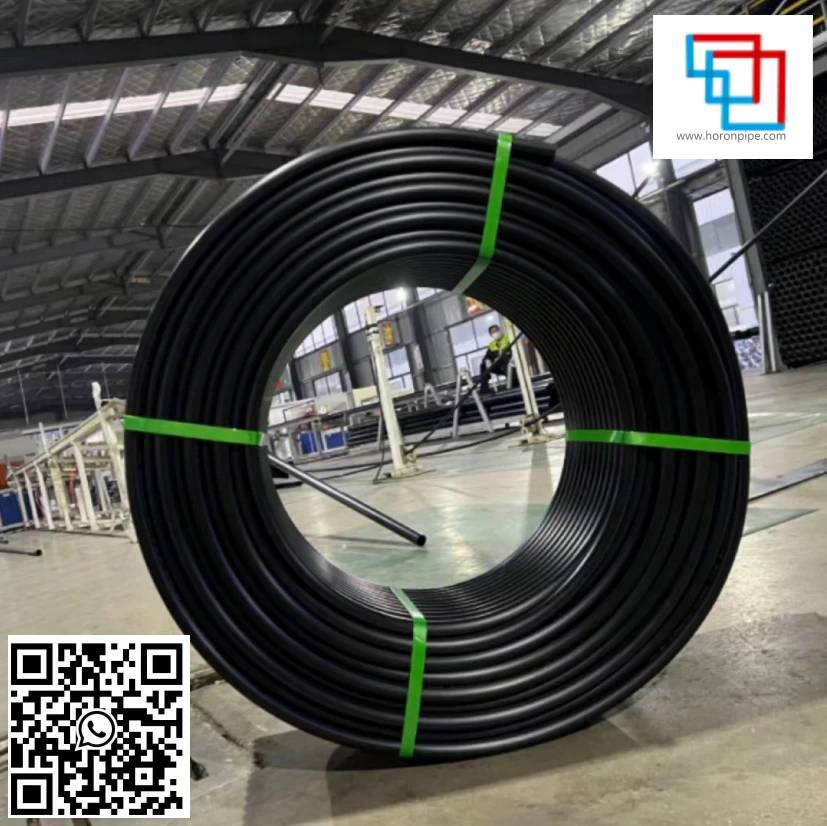

32mm HDPE Pipes in Coil - Durable, Flexible & Easy Installation

NewsJul.22,2025

-

DN100 PVC Pipes for Durable Well Casings | Corrosion-Resistant

NewsJul.22,2025

-

Durable DN100 PVC Pipes for Well Casings | Corrosion Resistant

NewsJul.21,2025

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025