Jul . 23, 2025 06:01 Back to list

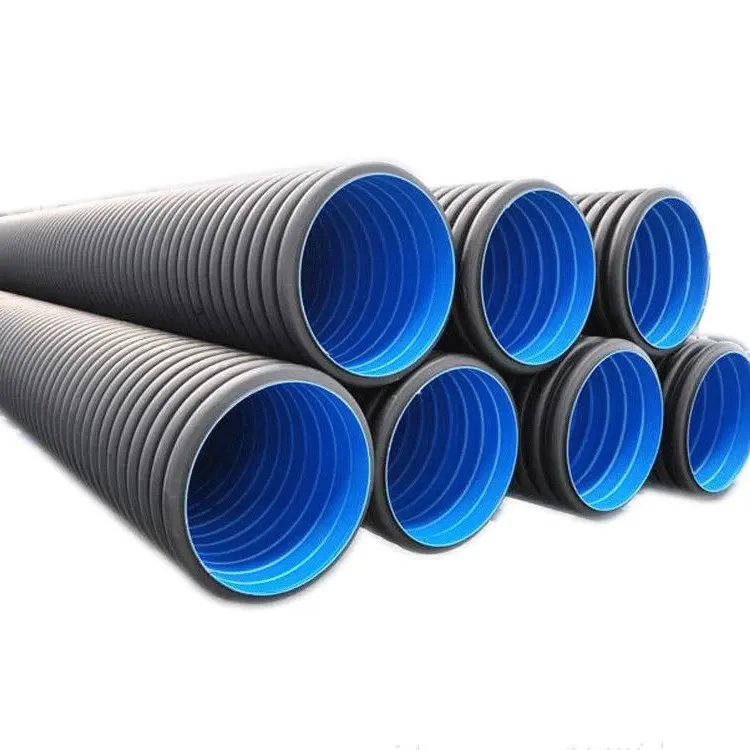

DN500 HDPE Double Wall Corrugated Drain Pipes for Efficient Drainage

As water management and urban infrastructure demands intensify globally, drainage solutions have become central to sustainable development. Among them, DN500 HDPE doule wall corrugated drain pipes emerge as a cornerstone product for modern drainage, combining structural robustness, eco-friendliness, and cost-effectiveness. HORON INTERNATIONAL — a leading manufacturer in piping solutions — delivers industry-grade products to meet these evolving needs.

Looking for reliable, certified, and technically advanced pipes? DN500 HDPE doule wall corrugated drain pipes

About HORON INTERNATIONAL

HORON INTERNATIONAL, headquartered in Shijiazhuang, China (No.499 West Heping Road, Shijiazhuang City, Hebei Province, China. 050020), has cemented its reputation as an authoritative provider of HDPE drainage pipe solutions. Our products meet rigorous national and international standards, blending expertise gained from extensive R&D and collaboration with global infrastructure partners. Explore our platform: https://www.horonpipe.com

🏢 Address: No.499 West Heping Road, Shijiazhuang City, Hebei Province, China.050020

Product Overview: DN500 HDPE doule wall corrugated drain pipes

The DN500 HDPE doule wall corrugated drain pipes by HORON INTERNATIONAL are manufactured using high-density polyethylene resin of superior grade. Featuring a unique double-wall structure — with an outer corrugated wall for high mechanical strength and an inner smooth surface for optimal hydraulics — this solution effectively addresses both rainwater and wastewater drainage.

Product link: https://www.horonpipe.com/dn500-hdpe-doule-wall-corrugated-drain-pipes.html

- 100% New HDPE Material, Environmentally friendly and corrosion-resistant

- High ring stiffness, excellent impact resistance, and flexibility

- Long life-span (>50 years) with minimal maintenance

- Quick joint installation, leak-proof performance

- Applications: Municipal drainage, highway engineering, rainwater & sewer systems, agriculture, industrial drainage, etc.

Technical Specifications — DN500 HDPE doule wall corrugated drain pipes

| Diameter (ID) | Standard Length | Ring Stiffness (SN) | Wall Structure | Material Grade | Joint Type | Working Temp. |

|---|---|---|---|---|---|---|

| DN500 mm | 6m / 9m | SN4 / SN8 / SN12.5 | Double Wall Corrugated | HDPE (PE80/PE100) | Socket/Bell & Spigot | -30°C~60°C |

| Compliance: ISO 21138-1, EN 13476-3, GB/T 19472.1-2004, ASTM F2306 | ||||||

Data Visualization: Parameters & Performance Trends

Industry Trends of DN500 HDPE doule wall corrugated drain pipes

Global urbanization and climate change have necessitated new approaches to water management and urban infrastructure. The adoption of DN500 HDPE doule wall corrugated drain pipes has surged due to:

- Cost Efficiency: Lightweight, labor-saving & reduced transportation expenses (PlasticsNews)

- Eco-Friendly Profile: 100% recyclable, reduces carbon footprint

- High Mechanical Performance: Withstands high soil loads and ground movements

- Long Service Life: Minimal maintenance, over 50 years, meets ISO/EN standards

- Technological Advances: Enhanced interlocking joints, anti-infiltration, and resistance to acids/alkalis

- Extensive Applications: From smart city micro-tunnels to large-scale flood management

Authorities and engineers continue to favor DN500 HDPE doule wall corrugated drain pipes for flagship infrastructure projects, driven by growing regulations around groundwater protection and sustainable urbanization.

[Research: Behavior of HDPE Corrugated Pipes in Field Applications]

Main Application Scenarios

- Municipal & City Drainage: Urban stormwater, flood mitigation and underground sewer pipelines

- Highway & Road Engineering: Roadbed subdrainage, culverts, roadside ditch networks

- Industrial Parks: Process wastewater, spillway channels, chemical drainage

- Agricultural Irrigation: Farmland sub-irrigation, drainage and water storage networks

- Airport & Port Infrastructure: Rapid-runoff drainage below runways and port logistics zones

- Landfill & Environmental: Leachate collection, landfill gas drainage, remediation systems

Professional FAQ — DN500 HDPE doule wall corrugated drain pipes Technical FAQ

- 1. What material is used for DN500 HDPE doule wall corrugated drain pipes?

-

They are manufactured using high-density polyethylene (HDPE) resin, typically PE80 or PE100 grade, known for its excellent chemical resistance, durability, and ecological safety.

[Reference - ScienceDirect: HDPE] - 2. What are the standard ring stiffness (SN) ratings for these pipes?

-

Commonly SN4, SN8, and SN12.5 (in kN/m²). For urban drainage and deep burying, SN8 and SN12.5 are recommended to withstand higher soil loads.

[ResearchGate Resource] - 3. How are the pipes joined, and what installation standards are applied?

-

Socket/Bell and Spigot joints, often with elastomeric sealing rings, are standard; installation should conform to ISO 21138-1, EN 13476-3, and ASTM F2306. Trench bedding, compaction, and joint testing are critical.

[See: HORON Application Standards] - 4. What is the typical lifetime of DN500 HDPE pipes?

- Service life exceeds 50 years under normal burial and installation conditions, validated by accelerated aging and field studies (Pipesforlife.eu).

- 5. What is the inner wall roughness, and why is it important?

- Roughness coefficient is commonly 0.008 (Manning’s n value), providing low frictional losses, high hydraulic flow, and self-cleaning capabilities.

- 6. Can DN500 pipes be used for chemical and industrial drainage?

-

Yes. HDPE’s chemical inertness makes it suitable for conveying acids, alkalis, and a wide range of industrial effluents.

[PPI Chemical Resistance Table] - 7. Are these pipes suitable for cold climates or freeze-thaw environments?

-

Absolutely. Functional temperature range: -30°C up to 60°C; pipe flexibility and resilience ensure stability under ground deformation and frost.

[Reference: PPI FAQ]

Why Choose DN500 HDPE doule wall corrugated drain pipes from HORON INTERNATIONAL?

- Expertise: 15+ years in HDPE drainage solutions; products developed with international experts and R&D partners

- Authoritativeness: Compliance with ISO, EN, and ASTM – Certified for major public works

- Trustworthiness: Verified case studies, transparent QC, end-to-end technical support

- Turnkey Service: Fast delivery, custom solutions, and on-site installation guidance

- Environmental Commitment: Green manufacturing, energy-saving production lines, life-cycle oriented development

- Competitive Pricing: Direct factory sales worldwide, no intermediaries, stable supply chain

Contact HORON INTERNATIONAL

📧 Email: moddy.zhang@gmail.com 📞 Phone/WhatsApp/WeChat: +8618632100415

🏢 Address: No.499 West Heping Road, Shijiazhuang City, Hebei Province, China.050020

- Performance and Life-Cycle Assessment of Double Wall Corrugated HDPE Pipes — Journal of Cleaner Production (Elsevier)

- Analyzing Field and Laboratory Behavior of HDPE Corrugated Pipes — ResearchGate

- Long-Term Performance of Corrugated HDPE Pipes — ASCE Proceedings

- Application Guidance from PPI (Plastic Pipe Institute)

-

32mm HDPE Pipes in Coil - Durable, Flexible & Easy Installation

NewsJul.22,2025

-

DN100 PVC Pipes for Durable Well Casings | Corrosion-Resistant

NewsJul.22,2025

-

Durable DN100 PVC Pipes for Well Casings | Corrosion Resistant

NewsJul.21,2025

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025