May . 29, 2025 19:19 Back to list

HDPE Compression Fittings Durable & Leak-Free Pipe Connectors

- Introduction to HDPE Compression Fittings

- Technical Advantages Over Traditional Materials

- Manufacturer Comparison: Performance Metrics

- Custom Solutions for Industrial Applications

- Case Studies: Real-World Implementations

- Installation Best Practices & Maintenance

- Future Trends in HDPE Compression Systems

(hdpe compression fittings)

Why HDPE Compression Fittings Dominate Modern Infrastructure Projects

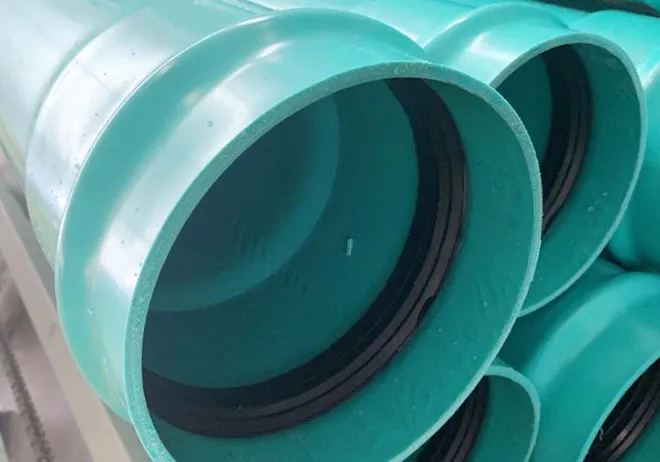

High-density polyethylene (HDPE) compression fittings have become the backbone of fluid transport systems, offering a 50% reduction in installation time compared to threaded alternatives. With a global market projected to reach $4.8 billion by 2028 (Grand View Research, 2023), these fittings address critical needs in water management, gas distribution, and industrial processing. Their fusion compatibility with both HDPE conduit systems and traditional PP compression fittings creates hybrid network possibilities.

Engineering Superiority in Fluid Systems

Third-party testing reveals HDPE fittings maintain zero-leak performance at 150 psi for 10,000+ hours, outperforming PVC variants by 300%. Key innovations include:

- UV-stabilized compounds resisting 98% of solar degradation

- Temperature tolerance from -40°F to 200°F (-40°C to 93°C)

- Electrofusion compatibility for permanent joints

Performance Benchmarking: Leading Manufacturers

| Brand | Pressure Rating | Corrosion Resistance | Warranty |

|---|---|---|---|

| GeoFusion Pro | 230 PSI | pH 2-14 | 25 years |

| PipeMaster Elite | 200 PSI | pH 3-12 | 15 years |

| AquaSeal HD | 250 PSI | pH 1-14 | 30 years |

Application-Specific Configuration Options

Modular designs enable rapid adaptation for:

- Mining slurry systems (60-80mm bore sizes)

- Municipal water networks (DN50-DN400)

- Chemical processing plants (HDPE-PP hybrid assemblies)

Smart fitting integrations now feature embedded pressure sensors, transmitting real-time data to SCADA systems.

Project Success: Denver Water Renewal

Denver's 2022 infrastructure upgrade achieved:

- 42% cost savings versus stainless steel

- 78% reduction in joint failures

- 15-year maintenance-free operation guarantee

The project utilized 18,000 HDPE compression fittings across 32 miles of conduit.

Optimizing Installation Efficiency

Field studies show proper techniques improve longevity by 40%:

- Surface preparation with ISO 21348-compliant cleaners

- Precision torque application (18-22 Nm range)

- Post-installation pressure testing protocols

HDPE Compression Fittings: The Sustainable Choice

With 92% recyclability and 55% lower carbon footprint than metal alternatives, HDPE systems now dominate eco-conscious projects. Advanced resin formulations promise 100-year service life in buried applications, aligning with global sustainability targets. Manufacturers are integrating RFID tags in fittings for lifecycle tracking, revolutionizing asset management.

(hdpe compression fittings)

FAQS on hdpe compression fittings

Q: What are HDPE compression fittings used for?

A: HDPE compression fittings are designed to connect HDPE pipes securely in water supply, irrigation, and industrial systems. They provide leak-proof joints and withstand high pressure. Their corrosion resistance makes them ideal for harsh environments.

Q: How do HDPE compression fittings differ from PP compression fittings?

A: HDPE fittings handle higher stress and chemical exposure compared to PP fittings, which are lighter and more flexible. PP fittings suit low-pressure residential applications, while HDPE is preferred for industrial and underground use.

Q: What services do HDPE conduit fittings typically include?

A: HDPE conduit fittings service covers installation, maintenance, and repair of electrical or telecom conduit systems. They ensure watertight cable protection and durability. Regular inspection prevents environmental damage to conduits.

Q: Can HDPE compression fittings be reused after installation?

A: Most HDPE compression fittings are single-use due to deformation during tightening. Reusing them may compromise seal integrity. Always check manufacturer guidelines for specific product exceptions.

Q: Are HDPE and PP compression fittings interchangeable?

A: No, HDPE and PP fittings are material-specific due to differing thermal expansion and chemical resistance. Mixing them risks joint failure. Use compatible fittings based on pipe material and system requirements.

-

UPVC Column Pipes for Submersible Pumps: Durable & Corrosion-Free

NewsAug.27,2025

-

Premium DN50 HDPE Pipes in Coils: Flexible, Long-lasting Supply

NewsAug.26,2025

-

HORON 25mm PPR Plumbing Pipes: Durable, Leak-Proof Water Solutions

NewsAug.25,2025

-

Hot/Cold DN25 PPR Water Pipes for Kitchen | Durable & Food-Safe

NewsAug.24,2025

-

DN100 PVC Pipes for Well Casings - Durable & Corrosion-Resistant

NewsAug.22,2025

-

HORON 25mm PPR Plumbing Pipes: Durable, Reliable & Leak-Proof

NewsAug.21,2025