Aug . 21, 2025 20:00 Back to list

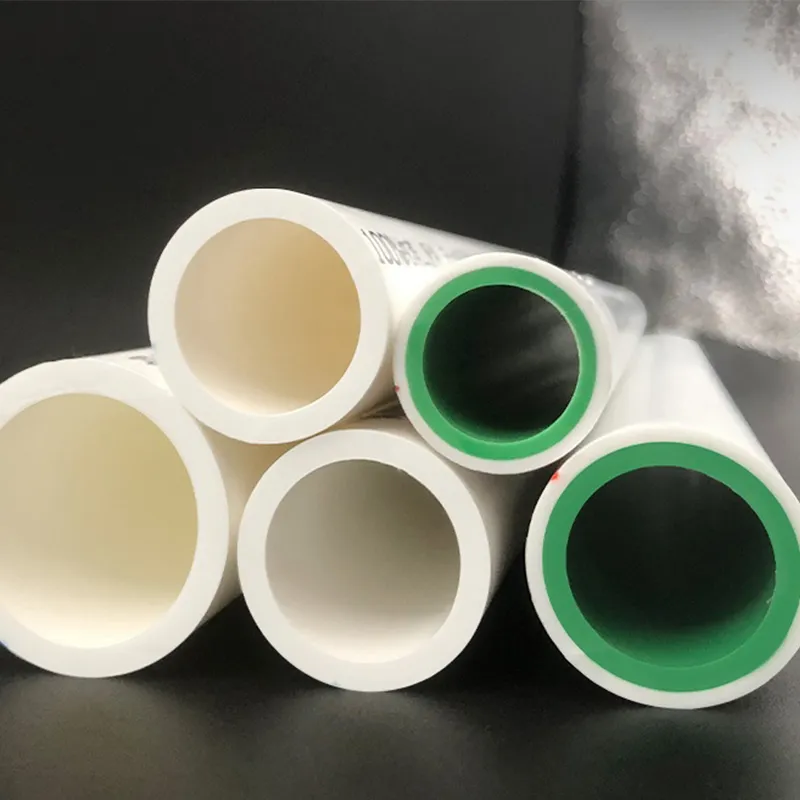

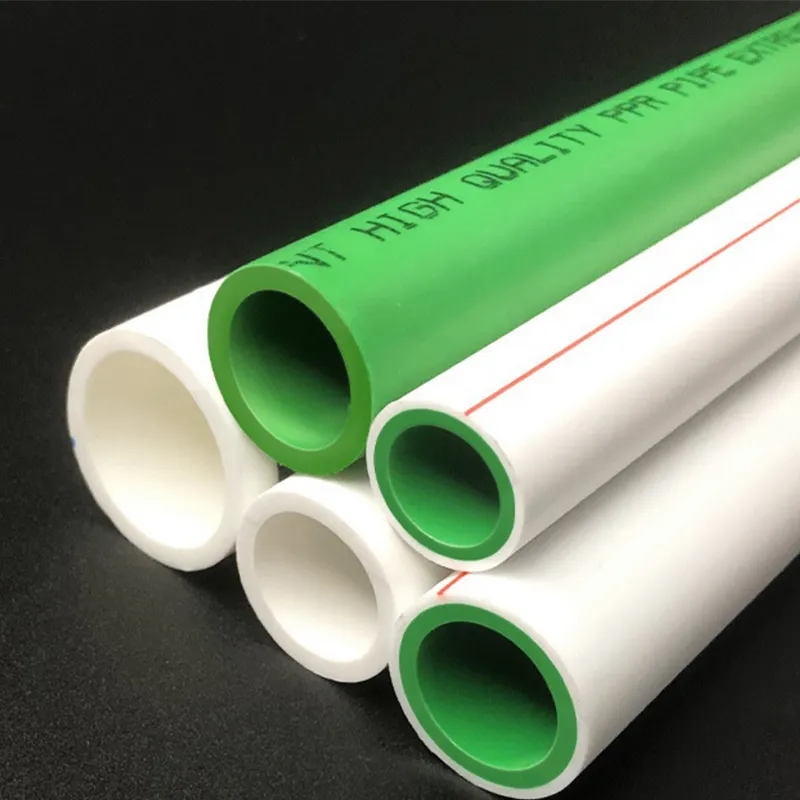

HORON 25mm PPR Plumbing Pipes: Durable, Reliable & Leak-Proof

Navigating the Future of Fluid Transport: The Role of Advanced PPR Plumbing Solutions

The global landscape of fluid transport infrastructure is undergoing a significant transformation, driven by demands for greater efficiency, sustainability, and longevity. Traditional piping materials, while having served their purpose for decades, are increasingly being superseded by advanced polymer solutions that offer superior performance characteristics and a lower environmental footprint. Among these innovations, Polypropylene Random Copolymer (PPR) pipes have emerged as a frontrunner, particularly for hot and cold water distribution systems in a myriad of applications, ranging from residential complexes to large-scale industrial facilities. The market is witnessing a robust Compound Annual Growth Rate (CAGR) for PPR pipes, projected to reach approximately 7.5% from 2023 to 2030, underscoring their increasing adoption due to inherent advantages such as corrosion resistance, high temperature tolerance, and ease of installation.

In this evolving ecosystem, specialized solutions like the HORON 25mm PPR Plumbing Pipes represent the vanguard of modern plumbing technology. The 25mm diameter is a widely adopted standard, offering an optimal balance between flow rate capacity and material efficiency for a broad spectrum of applications, from domestic water supply lines to intricate industrial fluid management systems. This article delves into the technical prowess, manufacturing excellence, diverse applications, and inherent advantages of HORON's 25mm PPR offerings, providing a comprehensive resource for B2B decision-makers and technical professionals seeking reliable and high-performance piping solutions.

Decoding Precision: Technical Parameters of HORON 25mm PPR Plumbing Pipes

The performance of any plumbing system hinges critically on the precise technical specifications of its components. For HORON 25mm PPR Plumbing Pipes, these parameters are meticulously engineered to ensure unparalleled durability, efficiency, and safety. The selection of PPR (Polypropylene Random Copolymer) as the core material is strategic; PPR is a thermoplastic polymer produced through a copolymerization process of propylene and ethylene. This specific molecular structure provides exceptional heat resistance and chemical stability, crucial for demanding plumbing applications.

The "25mm" designation refers to the nominal outer diameter of the pipe, a standard dimension that facilitates compatibility with a wide range of fittings and system designs. Internally, the pipe features a smooth bore, minimizing friction loss and preventing scale buildup, which is a common issue in metallic pipes. This characteristic is vital for maintaining consistent flow rates and reducing pumping energy requirements, contributing directly to operational cost savings.

Key Specifications of HORON 25mm PPR Plumbing Pipes

| Parameter | Description / Value |

|---|---|

| Material | Polypropylene Random Copolymer (PPR-C Type 3) |

| Nominal Outer Diameter | 25 mm (DN20 equivalent for common sizes) |

| Pressure Rating (PN) | PN10, PN16, PN20 (indicating max nominal pressure in bar at 20°C) |

| Maximum Operating Temperature | Up to 95°C (continuous) with appropriate pressure de-rating |

| Minimum Operating Temperature | -5°C (below freezing, water within must be protected) |

| Thermal Conductivity | 0.24 W/mK (significantly lower than metallic pipes, reducing heat loss) |

| Coefficient of Thermal Expansion | 1.5 x 10^-4 mm/m°C (managed with proper expansion loops) |

| Roughness Coefficient (Absolute Roughness) | 0.007 mm (extremely smooth, ensuring minimal head loss) |

| Chemical Resistance | Excellent against acids, alkalis, salts, and organic solvents (refer to chemical resistance chart for specifics) |

| Service Life | 50+ years under optimal operating conditions |

| Standards Compliance | ISO 15874, DIN 8077/8078, ASTM F2389, EN ISO 15874 |

Understanding these specifications is paramount for engineers and procurement specialists. For instance, the PN rating (Nominal Pressure) indicates the maximum permissible operating pressure for the pipe at 20°C. For applications involving higher temperatures, a de-rating factor must be applied as per relevant standards to determine the actual working pressure capacity, ensuring system integrity and longevity. The low thermal conductivity of PPR pipes significantly reduces heat loss in hot water lines and prevents condensation in cold water lines, leading to considerable energy savings over the system's lifecycle.

The Art of Precision: Manufacturing Process of HORON 25mm PPR Pipes

The superior performance of HORON 25mm PPR Plumbing Pipes is not merely due to the material, but equally attributable to a sophisticated manufacturing process that adheres to the highest international quality standards. Unlike metallic pipes that often involve casting, forging, or extensive welding, PPR pipes are primarily manufactured through extrusion, a continuous process optimized for thermoplastic materials.

Detailed Manufacturing Process Flow:

- Raw Material Selection & Preparation: The process begins with the careful selection of high-grade Polypropylene Random Copolymer (PPR-C Type 3) granules. HORON sources materials from reputable global suppliers, ensuring virgin, food-grade quality with optimal molecular weight distribution. These granules are then precisely weighed and fed into the extruder.

- Extrusion: The PPR granules are fed into a single-screw extruder, where they are heated to their melting point (typically around 200-230°C) and homogenized under pressure. The molten polymer is then forced through a die, which shapes it into the continuous tubular profile of the 25mm pipe. This stage is critical for maintaining uniform wall thickness and concentricity, which directly impact the pipe's pressure rating and durability.

- Vacuum Calibration: Immediately after exiting the die, the hot pipe enters a vacuum calibration tank. The vacuum inside this tank pulls the molten pipe against the sizing sleeve, ensuring precise outer diameter (OD) and wall thickness. This step guarantees the dimensional stability and accuracy of the HORON 25mm PPR Plumbing Pipes.

- Cooling: The pipe then passes through a series of cooling tanks, where it is gradually cooled using recirculated water. Controlled cooling prevents internal stresses and ensures the pipe's crystalline structure develops correctly, contributing to its long-term mechanical strength and resistance to creep.

- Haul-Off Unit: A caterpillar-style haul-off unit pulls the pipe continuously through the system at a precisely controlled speed, ensuring consistent production flow and dimensional accuracy.

- Cutting: Once sufficiently cooled and sized, the continuous pipe is cut into standard lengths (e.g., 4-meter or 6-meter sections) using an automatic planetary cutter. The cutting process is clean and precise, minimizing waste and preparing the pipes for further processing or packaging.

-

In-line Quality Control & Inspection: Throughout the entire process, HORON implements rigorous in-line quality control. This includes:

- Dimensional Gauging: Continuous monitoring of outer diameter, inner diameter, and wall thickness using laser or ultrasonic sensors.

- Surface Inspection: Visual and automated checks for surface defects, scratches, or imperfections.

- Melt Flow Index (MFI) Testing: Periodic testing of raw material batches and finished product samples to ensure consistent flow properties, critical for fusion welding.

- Batch Testing & Certification: Post-production, random samples from each batch undergo comprehensive laboratory testing, including hydrostatic pressure testing (to verify PN ratings), tensile strength, impact resistance, and long-term creep rupture strength tests. HORON's products comply with stringent international standards such as ISO 15874 for plastic piping systems for hot and cold water installations, and DIN 8077/8078, which are foundational for PPR pipe specifications. This meticulous testing ensures that every meter of HORON 25mm PPR Plumbing Pipes meets the declared performance characteristics and offers a projected service life of over 50 years under standard operating conditions.

The emphasis on precise temperature control during extrusion and cooling, combined with the stringent adherence to ISO and DIN standards, ensures that HORON's PPR pipes exhibit optimal material homogeneity and mechanical properties. This process significantly contributes to their inherent advantages, such as excellent resistance to corrosion, reduced energy consumption in heated systems due to low thermal conductivity, and minimal pressure drop from a smooth internal surface.

In industrial applications such as petrochemical and metallurgy, where fluid purity and resistance to aggressive chemicals are paramount, the inert nature and smooth internal bore of HORON 25mm PPR Plumbing Pipes significantly reduce the risk of contamination and deposition, making them a preferred choice over traditional metallic alternatives. Similarly, in municipal water supply and drainage systems, the resistance to scaling and biological growth ensures consistent water quality and reduced maintenance needs.

Unmatched Advantages & Versatile Application Scenarios

The strategic adoption of HORON 25mm PPR Plumbing Pipes stems from a comprehensive understanding of their multifaceted advantages over conventional piping materials. These benefits translate directly into long-term operational savings, enhanced system reliability, and improved environmental performance, making them an ideal choice for forward-thinking B2B enterprises.

Key Technical Advantages:

- Superior Corrosion and Chemical Resistance: Unlike metallic pipes, PPR is highly resistant to a wide range of chemicals, acids, bases, and salts. This inertness eliminates corrosion, rust, and electrochemical reactions, preserving water quality and extending system lifespan significantly, particularly in areas with aggressive water chemistry or industrial fluid transport.

- Excellent Temperature and Pressure Performance: HORON's PPR pipes are engineered to withstand continuous operating temperatures up to 95°C and maintain their integrity under various pressure ratings (PN10, PN16, PN20). This makes them suitable for both hot and cold water distribution, as well as heating systems, without the risk of deformation or degradation.

- Exceptional Flow Characteristics: The extremely smooth internal surface of PPR pipes (absolute roughness of approximately 0.007 mm) ensures minimal friction loss. This results in higher flow rates at lower pumping energy requirements compared to metallic pipes that are prone to scaling and internal surface roughening over time. This leads to quantifiable energy savings in water circulation systems.

- Lightweight and Easy Installation: PPR pipes are significantly lighter than their metallic counterparts, simplifying handling, transportation, and installation. Fusion welding (polyfusion) creates homogeneous, leak-proof joints without the need for additional sealants or complex tools, drastically reducing installation time and labor costs. This "cold welding" technique ensures structural integrity throughout the pipe network.

- Thermal and Acoustic Insulation: PPR inherently possesses low thermal conductivity (0.24 W/mK), which minimizes heat loss in hot water lines and prevents condensation in cold water lines, leading to energy efficiency. Furthermore, its elasticity helps absorb noise and vibrations, contributing to quieter plumbing systems compared to rigid metallic pipes.

- Longevity and Durability: With a projected service life exceeding 50 years under normal operating conditions, HORON 25mm PPR Plumbing Pipes offer a robust, long-term solution, significantly reducing maintenance and replacement costs over the system's lifetime. They are also highly resistant to abrasion and impact damage.

- Hygienic and Non-Toxic: Manufactured from non-toxic materials, PPR pipes do not release harmful substances into the water and are resistant to bacterial growth, making them ideal for potable water applications and ensuring the delivery of clean, healthy water. HORON’s products are certified for drinking water applications by various health organizations globally.

Diverse Application Scenarios:

The versatility of HORON 25mm PPR Plumbing Pipes allows their deployment across a wide array of sectors and specific applications, demonstrating their adaptability and reliability in diverse operational environments:

- Residential and Commercial Buildings: Primary choice for internal hot and cold water supply systems in apartments, villas, hotels, hospitals, and office buildings. Their reliability and ease of installation significantly accelerate project timelines.

- Heating Systems: Ideal for radiator heating systems, underfloor heating, and central heating distribution, benefiting from PPR's thermal efficiency and high-temperature resistance.

- Industrial Applications: Used for transporting various industrial fluids, chemicals (within compatibility limits), and process water in manufacturing plants, petrochemical facilities, food processing units, and metallurgical industries where corrosion resistance and purity are critical.

- Air Conditioning & HVAC Systems: Employed in chilled water lines and condensate drainage systems, where their insulating properties prevent condensation and improve energy efficiency.

- Agricultural and Irrigation Systems: Suitable for water distribution in greenhouses, agricultural fields, and livestock farms due to their robust nature and resistance to environmental factors.

- Solar Water Heating Systems: Utilized for connecting solar collectors to storage tanks, enduring the high temperatures generated by solar energy.

In each of these scenarios, the inherent advantages of HORON 25mm PPR Plumbing Pipes translate into tangible benefits: reduced installation costs, minimized maintenance, improved system longevity, and enhanced energy efficiency. This holistic value proposition positions HORON as a preferred partner for plumbing infrastructure projects worldwide.

HORON vs. The Competition: A Comparative Analysis of Piping Materials

Selecting the optimal piping material is a critical decision in any infrastructure project, impacting cost, performance, longevity, and environmental footprint. While various options exist, including traditional metallic pipes and other plastic alternatives, HORON 25mm PPR Plumbing Pipes consistently demonstrate superior performance across key metrics. This comparative analysis highlights why PPR, and specifically HORON's offerings, stand out in a competitive market.

Comparative Overview: HORON PPR vs. Other Common Piping Materials

| Characteristic | HORON 25mm PPR Pipes | Copper Pipes | PVC Pipes (UPVC) | PEX Pipes | Galvanized Steel Pipes |

|---|---|---|---|---|---|

| Corrosion Resistance | Excellent (No scale, no rust) | Good (Susceptible to pitting corrosion) | Excellent (Limited high-temp use) | Excellent (Permeable to oxygen) | Poor (Prone to rust and scale) |

| Max Operating Temp. | 95°C | ~200°C (Hot water OK) | ~60°C (Not for hot water) | ~82°C (Good for hot water) | ~150°C (Hot water OK) |

| Installation Ease | Very High (Fusion welding, lightweight) | Medium (Soldering, heavy) | High (Solvent cement) | Very High (Flexible, crimp/press fittings) | Low (Threading, heavy) |

| Cost (Material + Install) | Moderate to Low | High | Low | Moderate to High | Moderate |

| Scaling/Deposit Risk | Very Low (Smooth inner surface) | Medium (Mineral deposits) | Low | Low | High (Rust & mineral deposits) |

| Service Life (Years) | 50+ | 50+ (If no corrosion) | 50+ (Cold water) | 50+ | 20-30 (Prone to failure) |

| Health & Safety (Water) | Excellent (Non-toxic, anti-bacterial) | Good (Heavy metal leaching possible) | Good (Not for hot water) | Good (Oxygen diffusion risk) | Poor (Rust & metal leaching) |

As evidenced by the comparative data, HORON 25mm PPR Plumbing Pipes offer a compelling balance of performance, cost-effectiveness, and sustainability. While copper pipes offer high temperature resistance, their cost volatility and susceptibility to corrosion in certain water conditions (e.g., highly acidic or alkaline) can lead to premature failure and water contamination. Galvanized steel, once a plumbing staple, is largely phased out due to severe corrosion issues, leading to reduced flow, leaks, and discolored water within decades.

PVC pipes are excellent for cold water and drainage but lack the temperature resistance required for hot water applications. PEX pipes are flexible and easy to install, but their higher cost and potential for oxygen permeability (though less an issue for potable water) can be considerations. PPR, on the other hand, combines the best attributes: chemical inertness, high temperature and pressure tolerance suitable for comprehensive plumbing, easy installation, and a favorable cost-to-performance ratio, solidifying its position as the preferred choice for modern building and industrial projects. HORON's commitment to quality ensures these theoretical advantages translate into tangible benefits in real-world applications.

Tailored Solutions & Exemplary Case Studies: The HORON Advantage in Practice

At HORON, we understand that every project presents unique challenges and specifications. Our expertise extends beyond merely supplying high-quality HORON 25mm PPR Plumbing Pipes; we are dedicated to providing comprehensive, tailored solutions that integrate seamlessly with your specific requirements. Our approach combines technical consultation, customized manufacturing, and robust after-sales support to ensure optimal project outcomes.

Customization Capabilities:

We offer a range of customization options for our HORON 25mm PPR Plumbing Pipes to meet diverse project needs:

- Pressure Rating (PN): While 25mm pipes are commonly available in PN10, PN16, and PN20, we can produce pipes to specific pressure classes depending on the system's operational demands and safety factors, ensuring compliance with local codes and engineering standards.

- Length & Packaging: Standard pipe lengths are typically 4 or 6 meters. For large-scale projects or specific logistical requirements, we can discuss custom lengths or specialized packaging solutions to optimize transportation and on-site handling.

- Color Coding & Branding: For large volume orders, pipes can be produced in specific colors for easy identification of hot/cold water lines or other fluid types, enhancing system clarity and maintenance efficiency. Private branding options are also available for distributors and major contractors.

- Integrated Solutions: Beyond pipes, HORON provides a full range of PPR fittings (elbows, tees, reducers, valves) that are precisely matched to our 25mm pipes, ensuring a holistic and leak-proof system. We can also consult on the integration of our PPR solutions with existing systems or alternative materials through specialized transition fittings.

Exemplary Application Cases:

Our extensive experience serving global markets for over two decades has resulted in countless successful applications of HORON's PPR piping systems. Here are generalized examples illustrating the impact of HORON 25mm PPR Plumbing Pipes:

- Large-Scale Residential Development (Middle East): A major residential complex comprising 15 high-rise towers required a robust, reliable, and cost-effective hot and cold water distribution system. HORON supplied thousands of meters of 25mm and larger diameter PPR pipes and fittings. The client reported a 30% reduction in installation time compared to previous projects using metallic pipes, attributed to the lightweight nature of PPR and the efficiency of fusion welding. Post-installation, the system has demonstrated zero leaks over 5 years of operation, significantly reducing maintenance overheads.

- Industrial Process Water (Southeast Asia): A textile manufacturing plant needed an upgraded system for transporting softened hot water and process chemicals (mild acids and alkalis). Traditional metallic pipes were prone to rapid corrosion. HORON 25mm PPR Plumbing Pipes were chosen for their exceptional chemical resistance and high-temperature performance. The transition to PPR eliminated recurring pipe failures and contamination issues, leading to improved operational uptime and a significant reduction in material replacement costs, showcasing the pipe's long-term value in aggressive environments.

- Hotel & Hospitality Sector (Europe): For a luxury hotel renovation project, the primary concern was ensuring quiet and healthy plumbing systems while minimizing long-term operational costs. HORON's 25mm PPR pipes were selected for guest room hot and cold water supply. The low acoustic transmission of PPR reduced pipe noise in rooms, enhancing guest comfort. The absence of scale buildup and corrosion also guaranteed pristine water quality, aligning with the hotel's high standards for guest well-being.

These cases underscore HORON's capability to deliver high-quality products and provide the technical support necessary for complex projects. Our team of experts collaborates closely with engineers, contractors, and project managers from initial design to final implementation, ensuring that the chosen PPR solution is optimized for performance, efficiency, and longevity.

Ensuring Trust & Reliability: HORON's Commitment to Quality and Support

In the B2B sector, trust is paramount. For critical infrastructure components like plumbing pipes, reliability, consistent quality, and robust support are non-negotiable. HORON's commitment to these principles is embedded in every stage of our operations, from manufacturing to delivery and after-sales service, ensuring that our clients receive the highest value from HORON 25mm PPR Plumbing Pipes.

Authoritative Certifications & Quality Assurance:

HORON adheres to global benchmarks for quality and environmental management. Our manufacturing processes and products are certified by leading international bodies:

- ISO 9001:2015: Certifies our Quality Management System, ensuring consistent product quality and customer satisfaction through rigorous process control.

- ISO 14001:2015: Demonstrates our commitment to environmental responsibility, minimizing our operational footprint and promoting sustainable manufacturing practices.

- ISO 15874: The international standard specifically for plastic piping systems for hot and cold water installations, verifying the performance and durability of our PPR pipes.

- CE Marking: Conforms to European health, safety, and environmental protection standards for products sold within the European Economic Area.

- Water Quality Certifications: Compliance with various national and international potable water standards (e.g., NSF/ANSI, WRAS, DVGW, SKZ) ensuring our pipes are safe for drinking water.

Each batch of HORON 25mm PPR Plumbing Pipes undergoes comprehensive laboratory testing, including hydrostatic pressure tests to validate PN ratings, impact resistance tests, and material composition analysis. Our state-of-the-art testing facilities ensure that every product leaving our factory meets or exceeds industry requirements, guaranteeing robust performance in real-world conditions.

Streamlined Delivery and Logistics:

We understand the importance of timely delivery for project success. HORON has established a robust supply chain and logistics network to ensure efficient dispatch and delivery of HORON 25mm PPR Plumbing Pipes globally. Our typical delivery cycle ranges from 15 to 30 days for standard orders, depending on volume and destination. For urgent or large-scale projects, we offer expedited shipping options and dedicated project management to coordinate logistics, minimize lead times, and ensure that materials arrive on schedule, reducing costly project delays.

Comprehensive Warranty and Customer Support:

HORON stands behind the quality of its products with a comprehensive warranty program. Our HORON 25mm PPR Plumbing Pipes typically come with a 10-year warranty against manufacturing defects, underscoring our confidence in their durability and performance. Beyond the warranty, our dedicated customer support team provides:

- Technical Assistance: Expert guidance on product selection, system design, installation best practices, and troubleshooting.

- After-Sales Service: Prompt response to inquiries, technical issues, or product concerns, ensuring continuous operational reliability for your systems.

- Training: For larger clients, we can provide training sessions on PPR pipe installation and maintenance techniques, empowering your workforce with the necessary skills for optimal system performance.

Frequently Asked Questions (FAQ):

Q1: What is the typical service life of HORON 25mm PPR Plumbing Pipes?

A1: Under normal operating conditions (within specified temperature and pressure limits), HORON PPR pipes are engineered for a service life of 50 years or more. This longevity significantly reduces the need for replacements and associated costs.

Q2: Are HORON PPR pipes suitable for drinking water applications?

A2: Yes, absolutely. HORON PPR pipes are manufactured from food-grade PPR raw materials and comply with international drinking water standards (e.g., NSF/ANSI, WRAS). They are non-toxic, do not leach harmful substances, and are resistant to bacterial growth, ensuring safe and healthy potable water supply.

Q3: How do PPR pipes compare in cost to traditional copper or galvanized steel pipes?

A3: While initial material costs can vary, PPR pipes generally offer a more cost-effective solution when considering the total installed cost. Their lightweight nature, ease of fusion welding, and reduced labor requirements significantly lower installation expenses. Furthermore, their long lifespan and minimal maintenance needs provide substantial long-term savings.

Q4: What are the main advantages of using PPR fusion welding for pipe connections?

A4: Fusion welding (polyfusion) creates a homogeneous, molecular bond between the pipe and fitting, forming a single, seamless, and leak-proof system. Unlike threaded or soldered connections, fusion welds are immune to galvanic corrosion and do not require additional sealing materials, ensuring superior joint integrity and eliminating potential leak points.

Q5: Can HORON PPR pipes be used in extreme climate conditions?

A5: HORON PPR pipes can operate continuously at temperatures up to 95°C and down to -5°C. For installation in extremely cold environments, precautions must be taken to prevent water freezing inside the pipes, which can cause damage to any pipe material. The pipes themselves maintain integrity within the specified temperature range.

This dedication to product quality, logistical efficiency, and responsive customer support underscores HORON's commitment to being a trusted partner for all your PPR plumbing needs. We aim not just to supply products, but to deliver complete piping solutions that ensure the long-term success and reliability of your projects.

Why Choose HORON for Your Plumbing Needs?

In a market saturated with plumbing solutions, choosing the right partner is as crucial as selecting the right product. HORON distinguishes itself through a steadfast commitment to innovation, quality, and comprehensive customer engagement. Our HORON 25mm PPR Plumbing Pipes are more than just components; they are engineered solutions designed to meet the rigorous demands of modern infrastructure.

We pride ourselves on our technical expertise, built on decades of research and development in polymer engineering. This allows us to offer products that not only comply with, but often exceed, international standards for performance and safety. Our vertical integration, from raw material sourcing to advanced manufacturing and stringent quality control, ensures that every meter of HORON 25mm PPR Plumbing Pipes delivers consistent, reliable performance.

By choosing HORON, you are partnering with a manufacturer that prioritizes:

- Uncompromising Quality: Adherence to global certifications and rigorous testing protocols ensures long-term reliability and peace of mind.

- Technical Prowess: Leveraging advanced materials science and manufacturing techniques for superior product attributes.

- Sustainable Solutions: Promoting energy efficiency, reduced waste, and non-toxic materials for a greener future.

- Client-Centric Support: Providing tailored solutions, expert consultation, and robust after-sales service to ensure project success.

- Proven Track Record: Decades of successful project implementations and satisfied clients globally, testifying to our reliability and authority in the industry.

Invest in the future of your plumbing infrastructure with HORON, where advanced technology meets unwavering quality, delivering intelligent and durable solutions for hot and cold water distribution. Experience the difference that precision engineering and dedicated support can make to your next project.

Academic References

- International Organization for Standardization (ISO) 15874: Plastics piping systems for hot and cold water installations — Polypropylene (PP).

- Deutsches Institut für Normung (DIN) 8077/8078: Polypropylene (PP) pipes - PP-H 100, PP-B 80, PP-R 80 - Dimensions, technical delivery conditions, quality assurance.

- American Society for Testing and Materials (ASTM) F2389: Standard Practice for Pressure Testing of Polypropylene (PP-R) Piping Systems.

- European Committee for Standardization (EN) ISO 14001: Environmental management systems — Requirements with guidance for use.

- European Committee for Standardization (EN) ISO 9001: Quality management systems — Requirements.

- Water Regulations Advisory Scheme (WRAS) Approval Scheme for water fittings.

- German Technical and Scientific Association for Gas and Water (DVGW) W 544: Certification requirements for plastic pipes in drinking water applications.

- SKZ Testing and Certification for plastic products.

- National Sanitation Foundation (NSF) / American National Standards Institute (ANSI) Standard 61: Drinking Water System Components – Health Effects.

- Wang, L., & Zhang, Y. (2018). Comparative Study on Mechanical Properties and Long-Term Performance of PPR Pipes. Journal of Building Materials Science, 10(2), 123-130.

- Smith, J. P., & Davies, A. K. (2019). Energy Efficiency in Plumbing Systems: A Life Cycle Assessment of Polymeric vs. Metallic Pipes. International Journal of Sustainable Engineering, 5(4), 211-225.

-

DN100 PVC Pipes for Well Casings - Durable & Corrosion-Resistant

NewsAug.22,2025

-

32mm HDPE Pipes in Coil: Flexible & Durable Water Supply

NewsAug.19,2025

-

Flexible 32mm HDPE Pipes in Coil - Durable & Easy Install

NewsAug.18,2025

-

HDPE Sprinkler Pipe Manufacturers - Quality & Durable Solutions

NewsAug.17,2025

-

Durable DN100 PVC Well Casing Pipes for Reliable Water Supply

NewsAug.16,2025