Aug . 17, 2025 02:20 Back to list

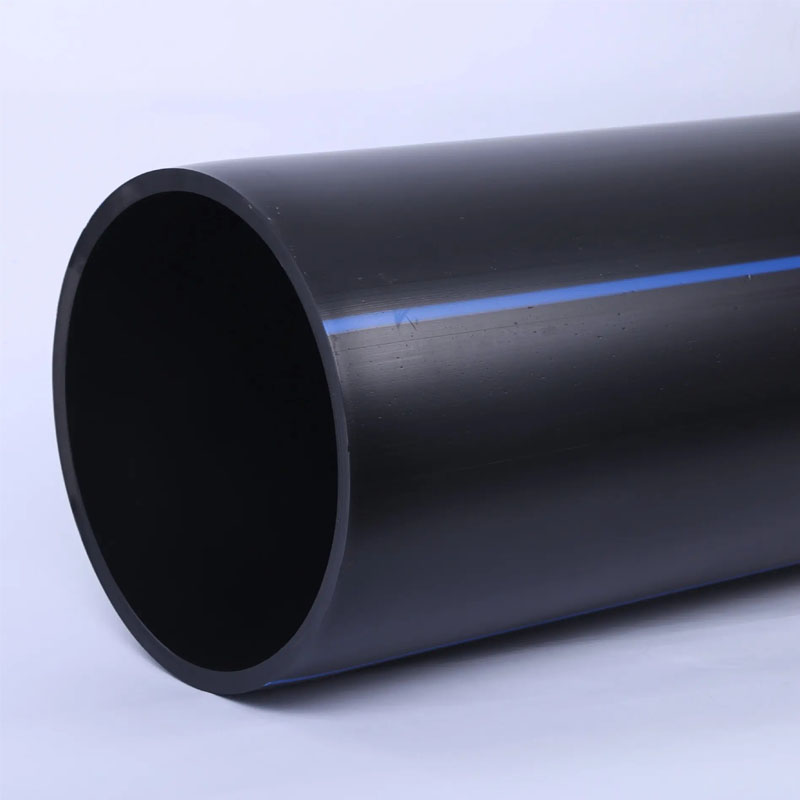

HDPE Sprinkler Pipe Manufacturers - Quality & Durable Solutions

The Growing Demand for High-Performance HDPE Sprinkler Pipes in Modern Irrigation

The landscape of global agriculture and industrial water management is undergoing a significant transformation, driven by an urgent need for efficient and sustainable water delivery systems. In this evolving scenario, High-Density Polyethylene (HDPE) pipes have emerged as a cornerstone solution, particularly for sprinkler and irrigation applications. Their inherent strength, flexibility, and exceptional durability make them an ideal choice for a diverse range of projects, from large-scale agricultural fields requiring precise water distribution to complex municipal and industrial water supply networks. The increasing scarcity of fresh water resources, coupled with the rising operational costs associated with traditional piping materials, has propelled the market for HDPE solutions forward. Leading hdpe sprinkler pipe manufacturers are at the forefront of this innovation, continuously developing advanced products that meet stringent international standards and deliver superior performance. These manufacturers are not merely supplying pipes; they are providing comprehensive piping solutions that contribute to water conservation, reduce system leakage, and extend the operational lifespan of critical infrastructure. The shift towards HDPE is a strategic move for organizations aiming to optimize their capital expenditures and operational efficiencies in the long term, ensuring reliable water supply even in challenging environmental conditions. This includes solutions like the DN150 HDPE pipes for irrigation, specifically designed for robust performance.

Understanding the Advanced Manufacturing Process of HDPE Sprinkler Pipes

The production of high-quality HDPE sprinkler pipes is a sophisticated process that demands precision engineering, rigorous material selection, and adherence to global manufacturing standards. Unlike metal pipes which often involve casting or forging, HDPE pipes are typically manufactured through an extrusion process. This begins with high-grade polyethylene resin, most commonly PE100 or PE80, known for its superior strength-to-density ratio and excellent long-term hydrostatic strength. The resin granules are fed into an extruder, where they are heated and melted into a homogenous mass. This molten plastic is then forced through a die to form the desired pipe diameter and wall thickness, such as those found in DN150 HDPE pipes for irrigation. Following extrusion, the hot pipe enters a vacuum calibration tank, where it is cooled and precisely sized. Subsequent cooling in water baths solidifies the pipe, which is then measured, marked for compliance (e.g., SDR rating, pressure class, manufacturer details), and cut to specified lengths. Quality control is integrated at every stage, from raw material inspection for melt flow index (MFI) and density, to in-process monitoring of dimensions and surface finish, culminating in final product testing. Strict adherence to international standards like ISO 4427, ASTM F714, and ANSI ensures that the pipes meet performance requirements for pressure rating, impact resistance, and resistance to rapid crack propagation. The inherent flexibility of HDPE, coupled with its resistance to corrosion, abrasion, and chemical attack, contributes to an impressive service life often exceeding 50 years, even in harsh conditions. These pipes are extensively used across industries such as agriculture for drip and sprinkler irrigation, municipal water supply and drainage systems, mining, and even petrochemical applications where corrosive fluid transfer is required. The seamless integration of advanced manufacturing techniques by skilled hdpe sprinkler pipe manufacturers ensures that the end product offers exceptional energy efficiency due to low friction losses and superior leak-free performance when correctly installed using fusion welding techniques, presenting a significant advantage over traditional materials.

Key Technical Parameters and Performance Metrics of HDPE Sprinkler Pipes

For B2B decision-makers and technical personnel, a deep understanding of the technical specifications of HDPE sprinkler pipes is paramount for selecting the optimal solution for their projects. The performance of these pipes is primarily characterized by several critical parameters. The Standard Dimension Ratio (SDR) defines the relationship between the pipe's outer diameter and its wall thickness, directly correlating with the pipe's pressure rating; a lower SDR indicates a thicker wall and higher pressure capacity. Pressure Nominal (PN) rating, expressed in bars, specifies the maximum operating pressure the pipe can safely withstand at a given temperature, typically 20°C. Material grade, predominantly PE100, signifies the minimum required strength (MRS) of the polyethylene compound, indicating its long-term hydrostatic performance. For a DN150 HDPE pipe, the outer diameter (OD) would typically be 160mm. Its wall thickness would vary based on the SDR, for instance, an SDR17 pipe would have a wall thickness of approximately 9.5mm, suitable for PN10 (10 bar) pressure, making it ideal for many irrigation applications. The Melt Flow Index (MFI) is another critical parameter, indicating the viscosity and processability of the polymer, crucial for consistent extrusion. Furthermore, the hydrostatic strength, determined through long-term pressure tests, ensures the pipe’s integrity over its expected service life. HDPE sprinkler pipe manufacturers also emphasize resistance to ultraviolet (UV) degradation, critical for above-ground installations, and resistance to slow crack growth (SCG) and rapid crack propagation (RCP), which prevent catastrophic failures. These technical properties, backed by extensive testing and certification, guarantee that the pipes can endure dynamic operational conditions, including pressure surges and temperature fluctuations, providing reliable and long-lasting performance in demanding environments like large-scale agricultural irrigation or industrial water transfer systems.

Typical Specifications for DN150 HDPE Pipes for Irrigation (PE100)

| Parameter | Value / Range | Significance |

|---|---|---|

| Nominal Diameter (DN) | DN150 | Standard size for medium to large flow irrigation systems. |

| Outer Diameter (OD) | 160 mm | Ensures compatibility with standard fittings. |

| Material Grade | PE100 (MRS ≥ 10.0 MPa) | High resistance to internal pressure, enhanced durability. |

| Standard Dimension Ratio (SDR) | SDR17, SDR13.6, SDR11 | Determines wall thickness and pressure rating (e.g., SDR17 for PN10, SDR11 for PN16). |

| Pressure Nominal (PN) | PN10, PN12.5, PN16 | Max working pressure at 20°C (10 bar, 12.5 bar, 16 bar respectively). |

| Service Life | >50 years | Exceptional longevity reduces replacement frequency. |

| Corrosion Resistance | Excellent | Impervious to chemical attack, rust, and microbial growth. |

Diverse Application Scenarios and Distinct Technical Advantages

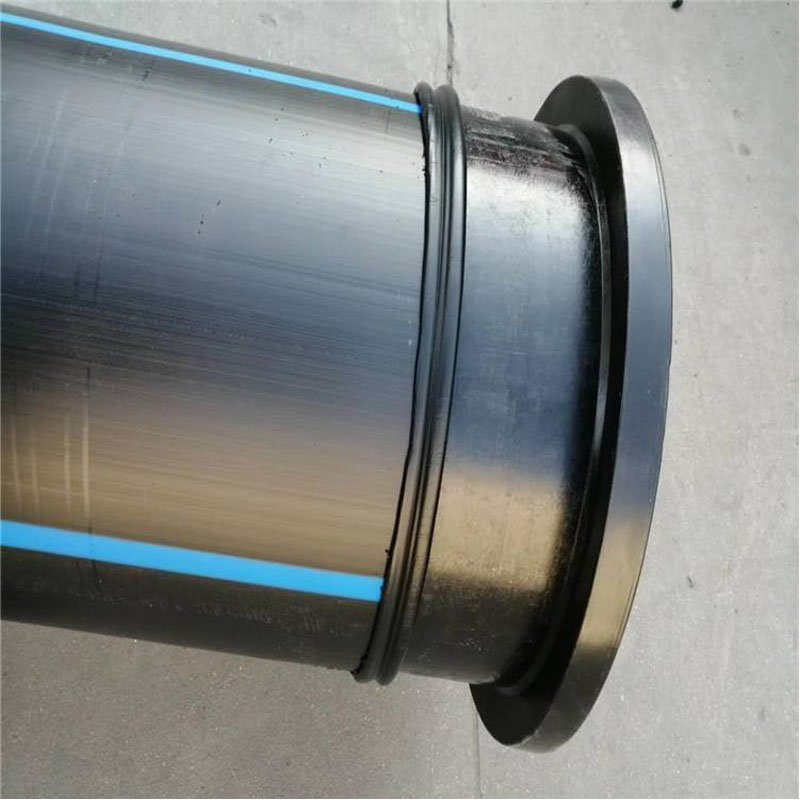

The versatility of HDPE sprinkler pipes extends their utility far beyond traditional agricultural irrigation. These pipes are instrumental in sophisticated large-scale irrigation systems, including center pivot, linear move, and drip irrigation setups, delivering water precisely where needed to maximize crop yield while minimizing waste. Their robust nature also makes them ideal for municipal water supply and distribution networks, where reliability and leak prevention are critical. In industrial settings, HDPE pipes are increasingly used for transporting process water, slurries, and even certain corrosive chemicals due to their exceptional chemical resistance. Mining operations benefit from their abrasion resistance when conveying abrasive materials. The core technical advantages contributing to this widespread adoption are manifold. Firstly, the material's inherent flexibility allows for longer pipe runs with fewer fittings, significantly reducing installation time and costs compared to rigid materials like PVC or metal. This flexibility also makes them highly resistant to ground movement, seismic activity, and frost heave. Secondly, HDPE pipes can be joined using heat fusion (butt fusion, electrofusion), creating a monolithic, leak-free system that eliminates potential points of leakage common in traditional gasketed or mechanical joints. This translates directly to significant water savings and reduced operational costs over the system's lifespan. Thirdly, their smooth inner bore minimizes friction losses, which in turn reduces pumping energy requirements, leading to substantial energy savings and lower carbon footprints. Furthermore, HDPE is non-toxic and resistant to biological growth, making it safe for potable water applications. These collective benefits position HDPE pipes, particularly those from reputable hdpe sprinkler pipe manufacturers, as a superior and sustainable choice for demanding fluid transfer applications across various sectors, ensuring long-term operational integrity and cost-effectiveness.

Strategic Considerations for Selecting an HDPE Sprinkler Pipe Manufacturer

Choosing the right hdpe sprinkler pipe manufacturers is a critical decision that directly impacts the success, longevity, and cost-effectiveness of any piping project. B2B purchasers must look beyond just price, focusing on a holistic evaluation of a manufacturer's capabilities, quality assurance, and support services. Key criteria for selection include the manufacturer's adherence to international quality standards such as ISO 9001 for quality management and ISO 14001 for environmental management, signifying a commitment to consistent, high-quality production and responsible practices. Verification of product certifications, such as those from recognized bodies like NSF, WRAS, or equivalent local authorities, ensures that the pipes meet specific performance and safety benchmarks for their intended application. A reputable manufacturer will possess advanced testing facilities to conduct rigorous internal tests, including hydrostatic pressure tests, impact resistance tests, and melt flow rate analysis, ensuring every batch meets stringent specifications. Furthermore, their experience in the market, demonstrated by years of operation and a portfolio of successful projects, provides a strong indicator of their expertise and reliability. Evaluating their capacity for customized solutions, such as specific lengths, colors, or co-extruded layers for enhanced UV protection, is also vital for projects with unique requirements. Finally, the scope and quality of their after-sales support, including technical assistance, installation guidance, and warranty terms, are crucial for long-term operational peace of mind. A manufacturer committed to continuous innovation, exploring new materials and production techniques to improve pipe performance, will ultimately provide superior value. This comprehensive evaluation framework helps organizations forge partnerships with manufacturers who can truly deliver high-quality, reliable, and durable HDPE piping solutions tailored to their precise needs.

Manufacturer Comparison Checklist

| Criterion | Ideal Manufacturer Attributes |

|---|---|

| Quality Certifications | ISO 9001, ISO 14001, NSF, WRAS, CE (as applicable) |

| Product Range & Capacity | Comprehensive pipe sizes (e.g., DN150 to larger), pressure ratings, custom solutions. Large production capacity. |

| Raw Material Sourcing | Uses virgin, certified PE100/PE80 resins from reputable global suppliers. |

| Technical Support | Provides detailed technical data, installation guides, and prompt expert advice. |

| Delivery & Logistics | Reliable lead times, efficient global shipping capabilities, robust packaging. |

| After-Sales Service | Strong warranty policy, responsive customer service for issue resolution. |

| Industry Reputation & Experience | Established market presence, positive client testimonials, portfolio of diverse projects. |

Customization and Unparalleled Customer Support from Leading Providers

Beyond standardized products, the ability of hdpe sprinkler pipe manufacturers to offer tailored solutions is increasingly important for complex projects with unique specifications. Customization can encompass various aspects, including non-standard pipe lengths to minimize on-site welding, specific external coatings for enhanced UV or abrasion resistance, co-extruded inner layers for specialized fluid transport, or even custom branding and color coding for project identification. A truly client-centric manufacturer collaborates closely with project engineers and procurement teams from the initial design phase through to project completion. This consultative approach ensures that the proposed DN150 HDPE pipes for irrigation or other custom sizes are perfectly aligned with the technical, operational, and budgetary requirements of the project. Furthermore, reliable service extends to efficient logistics and supply chain management. This includes clear communication regarding lead times, which typically range from 2 to 4 weeks for standard orders, though this can vary based on volume and customization. Manufacturers with robust global distribution networks can ensure timely and secure delivery, minimizing project delays and additional costs. Critical to building trust is a transparent and comprehensive warranty commitment, typically ranging from 10 to 15 years, covering manufacturing defects and material integrity. This provides clients with long-term assurance regarding their investment. Responsive customer support, including technical assistance for installation guidance, fusion training, and swift resolution of any unforeseen challenges, is a hallmark of leading manufacturers. They view client relationships as partnerships, ensuring continuous support throughout the product’s lifecycle, from selection and installation to long-term operation. This holistic commitment to quality, customization, and unwavering support differentiates top-tier suppliers in the competitive market.

Proven Success: Case Studies and Building Client Trust

The credibility of hdpe sprinkler pipe manufacturers is largely cemented by their track record of successful project deliveries and positive client testimonials. For instance, consider a large-scale agricultural development in a semi-arid region where traditional metal piping suffered from severe corrosion and frequent leaks, leading to significant water loss and maintenance costs. Upon transitioning to a comprehensive HDPE piping system, including DN150 HDPE pipes for irrigation supplied by a trusted manufacturer, the farm reported a 30% reduction in water consumption due to the leak-free fusion joints and improved hydraulic efficiency. Furthermore, maintenance expenditures dropped by 50% within the first two years, showcasing the long-term economic benefits. Another notable case involved an industrial facility upgrading its wastewater treatment plant. Facing aggressive chemical effluent and demanding operational pressures, the facility opted for HDPE pipes, specifically engineered to withstand corrosive environments. The chosen manufacturer provided not only the pipes but also extensive technical consultation on pipe layout and fusion welding techniques, ensuring a robust and reliable system. This collaboration resulted in a highly resilient system that has operated flawlessly for over a decade, outperforming previous materials and significantly reducing environmental risks. These real-world applications underscore the tangible advantages and superior performance of well-manufactured HDPE pipes. Companies committed to excellence often highlight their service longevity, with many having over 15-20 years of dedicated experience in polyethylene pipe production. They often cite compliance with major international standards like ISO 4427 and EN 12201, providing authoritative backing for their product quality. By consistently delivering reliable products and exceptional support, these manufacturers build deep, enduring trust with their clients, making them preferred partners for critical infrastructure projects worldwide.

Frequently Asked Questions (FAQs) about HDPE Sprinkler Pipes

Navigating the technical landscape of piping solutions often brings forth common questions from B2B clients. Below are some frequently asked questions addressed by experienced hdpe sprinkler pipe manufacturers to clarify key aspects of HDPE pipe selection, installation, and performance.

Q1: What is the typical lifespan of HDPE sprinkler pipes, and how does it compare to other materials?

HDPE pipes are renowned for their exceptional longevity, with a design life often exceeding 50 to 100 years under normal operating conditions. This significantly surpasses the typical lifespan of traditional materials like PVC (around 20-30 years) or metallic pipes (prone to corrosion and scaling, leading to premature failure). The resistance of HDPE to corrosion, abrasion, chemical attack, and fatigue is a primary factor in its extended service life, making it a highly sustainable and cost-effective long-term investment for irrigation and water transfer systems.

Q2: Are HDPE pipes suitable for all types of water, including recycled or highly mineralized water?

Yes, HDPE pipes exhibit excellent chemical resistance, making them suitable for transporting a wide variety of fluids, including potable water, wastewater, recycled water, and even water with high mineral content or dissolved chemicals. Unlike metallic pipes, HDPE does not corrode or scale, which ensures consistent flow rates over time and prevents the buildup of deposits that can clog sprinklers or drip emitters. This property is particularly beneficial in agricultural settings where water sources may be diverse and contain various dissolved solids.

Q3: What are the primary methods for joining HDPE pipes, and how secure are these joints?

The primary methods for joining HDPE pipes are heat fusion, specifically butt fusion and electrofusion. Butt fusion involves heating the ends of two pipes and pressing them together to form a strong, homogenous joint that is as strong as the pipe itself. Electrofusion utilizes specialized fittings with integrated heating coils that melt the pipe and fitting surfaces together. Both methods create leak-free, monolithic joints, eliminating the weak points associated with mechanical or gasketed connections. This ensures the integrity of the entire piping system, significantly reducing water loss and maintenance requirements.

Q4: Can HDPE pipes be used in extreme temperatures?

HDPE pipes maintain their flexibility and performance across a broad temperature range, typically from -40°C to +60°C. While their pressure rating may need to be de-rated at higher temperatures, their resistance to freezing and thawing cycles is superior to brittle materials. The inherent flexibility of HDPE allows it to expand and contract without damage, and it can even tolerate minor freezing within the pipe without bursting. This makes them highly suitable for regions experiencing significant temperature fluctuations, from very cold winters to hot summers.

Authoritative References

- ISO 4427-2:2019, Plastics piping systems — Polyethylene (PE) pipes and fittings for water supply — Part 2: Pipes.

- ASTM F714-13, Standard Specification for Polyethylene (PE) Plastic Pipe (SDR-PR) Based on Outside Diameter.

- EN 12201-2:2011+A1:2013, Plastics piping systems for water supply, and for drainage and sewerage under pressure - Polyethylene (PE) - Part 2: Pipes.

- The Plastics Pipe Institute (PPI) Handbook of Polyethylene Pipe.

- Water Environment Federation, Manual of Practice No. 8, Design of Wastewater and Stormwater Pumping Stations.

-

Durable DN100 PVC Well Casing Pipes for Reliable Water Supply

NewsAug.16,2025

-

HORON 25mm PPR Plumbing Pipes: Durable, Leak-Proof Water Systems

NewsAug.15,2025

-

Durable UPVC Column Pipes for Submersible Pumps | Efficient Water Flow

NewsAug.14,2025

-

DN100 PVC Well Casing Pipes - Durable & Corrosion-Resistant

NewsAug.13,2025

-

Flexible 32mm HDPE Pipes in Coil | Durable Water & Gas Lines

NewsAug.12,2025