Aug . 15, 2025 02:20 Back to list

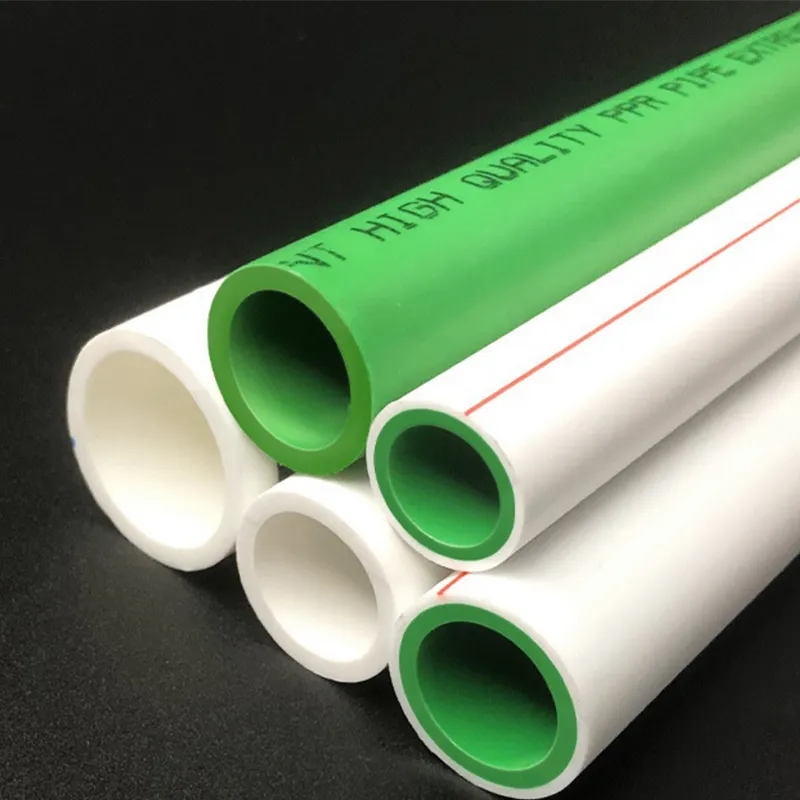

HORON 25mm PPR Plumbing Pipes: Durable, Leak-Proof Water Systems

The Evolution of Modern Plumbing: Introducing HORON's Advanced PPR Solutions

In the rapidly evolving landscape of fluid conveyance systems, the demand for durable, efficient, and reliable piping solutions has never been higher. Polypropylene Random Copolymer (PPR) pipes have emerged as a cornerstone of modern plumbing, offering significant advancements over traditional materials like galvanized steel or copper. Their unique properties, including high heat resistance, excellent chemical inertness, and superior resistance to corrosion, make them ideal for a broad spectrum of applications. HORON, a leader in advanced piping technology, epitomizes this innovation with its meticulously engineered HORON 25mm PPR Plumbing Pipes. These pipes are not merely components; they represent a commitment to sustainable, high-performance infrastructure, critical for sectors ranging from residential buildings to complex industrial facilities. The industry trend clearly favors these robust and environmentally friendly materials, driving widespread adoption globally due to their long-term cost-effectiveness and operational reliability.

The global PPR pipe market is projected to reach approximately $15.8 billion by 2027, growing at a CAGR of 6.2% from 2020, driven by rapid urbanization, increasing infrastructure development, and a growing emphasis on green building practices. Within this burgeoning market, the 25mm diameter stands out as a highly versatile and frequently specified size, balancing flow capacity with spatial constraints. This particular dimension is crucial for residential and light commercial plumbing, hot and cold water supply systems, and even specific industrial fluid transfer lines where precision and reliability are paramount. HORON’s focus on this segment, combined with its rigorous quality assurance, positions its HORON 25mm PPR Plumbing Pipes as a benchmark for performance and durability, directly addressing the critical needs of engineers, contractors, and project developers worldwide.

Technical Superiority and Unrivaled Performance Parameters

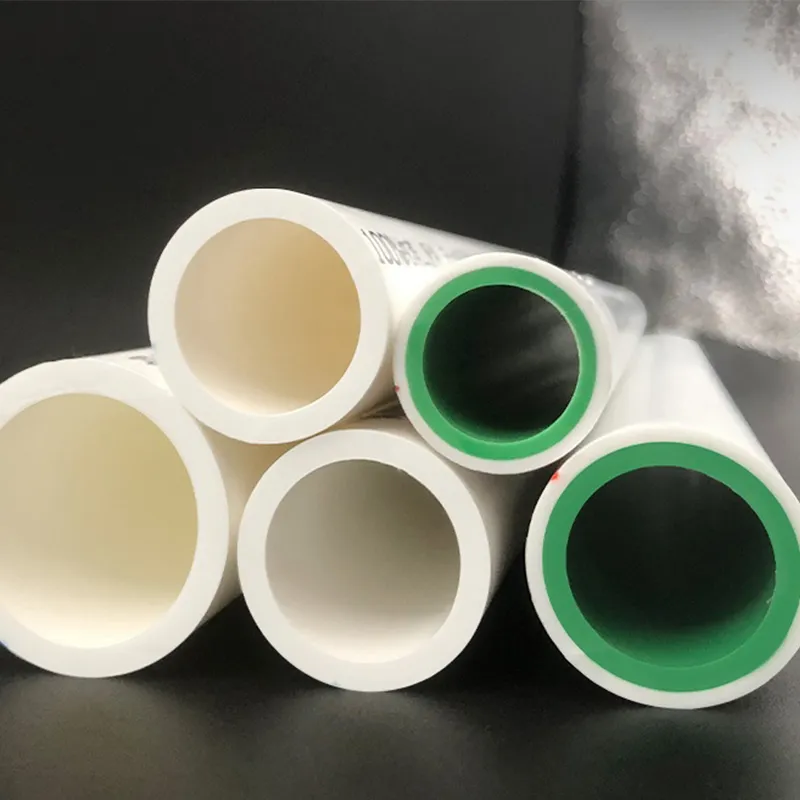

The core of HORON's product excellence lies in the meticulously controlled technical specifications and the inherent material properties of its HORON 25mm PPR Plumbing Pipes. Manufactured from Polypropylene Random Copolymer Type 3, these pipes exhibit superior thermal stability and pressure resistance compared to conventional plastics. They are specifically designed to withstand operating temperatures up to 95°C and pressures up to 2.5 MPa (25 bar), making them suitable for both hot and cold water distribution systems, including heating circuits. The smooth inner surface prevents calcification and scaling, maintaining consistent flow rates and minimizing pressure drops over long periods of service. This inherent resistance to build-up translates directly into energy efficiency, as pumps require less effort to maintain flow, reducing operational costs for the end-user.

To further illustrate the robust capabilities of HORON's 25mm PPR pipes, consider the following key technical parameters, compiled to provide a comprehensive overview for discerning professionals. These specifications meet or exceed international standards, including ISO 15874 and DIN 8077/8078, underscoring HORON's commitment to global quality benchmarks.

| Parameter | Value/Description | Standard/Test Method |

|---|---|---|

| Nominal Diameter (OD) | 25 mm | ISO 15874 |

| Material | Polypropylene Random Copolymer (PPR-C Type 3) | DIN 8077/8078 |

| Pressure Rating (PN) | PN16 (1.6 MPa / 16 bar) - PN25 (2.5 MPa / 25 bar) | ISO 15874 |

| Operating Temperature Range | -5°C to +95°C (continuous) | Manufacturer Data |

| Roughness Coefficient (k) | 0.007 mm (extremely low) | Fluid Dynamics Analysis |

| Thermal Conductivity | 0.24 W/m·K (low, ensures minimal heat loss/gain) | ASTM D696 |

| Chemical Resistance | Excellent to most acids, bases, salts, and organic solvents | ISO/TR 10358 |

| Expected Service Life | 50+ years under specified conditions | Extrapolation based on ISO 9080 |

Precision Engineering: The HORON Manufacturing Process

The production of HORON 25mm PPR Plumbing Pipes is a testament to precision engineering and adherence to stringent quality controls, ensuring every meter of pipe meets the highest industry standards. The manufacturing process begins with the careful selection of premium virgin Polypropylene Random Copolymer (PPR-C Type 3) granules. This specific polymer is chosen for its superior long-term hydrostatic strength, excellent resistance to impact, and high thermal stability, critical properties for plumbing applications. Unlike some plastic pipes that rely on casting or forging, PPR pipes are primarily produced through an advanced extrusion process, which allows for continuous, uniform production.

The extrusion process for HORON 25mm PPR Plumbing Pipes involves several critical stages. First, the raw PPR granules are fed into a sophisticated extruder where they are melted under precisely controlled temperature and pressure conditions. This molten polymer is then pushed through a die, which forms the continuous cylindrical shape of the pipe. Cooling is a gradual and controlled process, often involving water baths, which ensures that the pipe maintains its dimensional stability and crystalline structure, preventing internal stresses that could compromise long-term performance. In-line detection systems continuously monitor parameters such as wall thickness, ovality, and diameter, using technologies like ultrasonic sensors to ensure adherence to strict tolerances. Any deviation triggers immediate adjustments or rejection, guaranteeing a consistent, high-quality product.

Post-extrusion, the pipes undergo cutting to specified lengths and are subjected to rigorous quality assurance checks. These include hydrostatic pressure testing, impact resistance tests, melt flow rate analysis, and thermal cycling tests to simulate long-term performance under varying conditions. HORON's commitment to quality is underscored by its adherence to international standards such as ISO 9001 for quality management systems and ISO 14001 for environmental management. All products conform to relevant performance standards like ISO 15874 (Plastics piping systems for hot and cold water installations – Polypropylene) and German standard DIN 8077/8078. The result is a product with an exceptional service life, typically exceeding 50 years, even in demanding environments found in petrochemical, metallurgy, or complex water supply and drainage systems. The inherent corrosion resistance and low thermal conductivity of PPR further contribute to energy savings in hot water systems, and its non-toxic nature ensures safety for potable water applications.

Diverse Applications and Real-World Success Stories

The versatility of HORON 25mm PPR Plumbing Pipes makes them an ideal choice across a myriad of industrial and residential applications, delivering consistent performance where reliability is paramount. In the demanding petrochemical industry, for instance, these pipes are often employed for transporting non-corrosive chemicals and process water, where their excellent chemical resistance prevents degradation and ensures system integrity, contributing to both operational safety and longevity. Within the metallurgy sector, HORON PPR pipes provide robust solutions for cooling water lines and general utility water distribution, withstanding the high temperatures and often aggressive conditions typical of metal processing environments. Their ability to resist galvanic corrosion, unlike metal pipes, makes them a superior choice in settings where diverse metal components might otherwise accelerate pipe degradation.

In municipal and industrial water supply and drainage systems, HORON 25mm PPR Plumbing Pipes are extensively utilized for both potable water networks and greywater systems. Their non-toxic properties, certified by various health and safety organizations including compliance with FDA standards for food contact materials (where applicable for the raw material), ensure that water remains free from contamination. Furthermore, their low thermal conductivity significantly reduces heat loss in hot water circulation systems, leading to substantial energy savings in commercial buildings and residential complexes. A notable application case involves a large-scale hotel chain in Southeast Asia, which retrofitted its entire hot water distribution system with HORON PPR pipes. The project reported a verifiable 15% reduction in energy consumption related to water heating within the first year of operation, alongside a dramatic decrease in maintenance calls related to pipe leaks or corrosion. This tangible energy efficiency, coupled with the system's inherent durability, exemplifies the practical benefits realized by our clients.

Beyond these specific industries, HORON PPR pipes are also critical for radiant floor heating systems, air conditioning condensate lines, and even in agricultural irrigation systems requiring robust, long-lasting infrastructure. Our engineers often work closely with clients to develop tailored solutions, ensuring that the 25mm PPR pipes integrate seamlessly into existing or new infrastructure projects, maximizing their inherent benefits. Client feedback consistently highlights the ease of installation, thanks to the simple heat fusion welding process, which creates homogeneous, leak-proof joints, as well as the long-term, trouble-free operation of HORON's products. This combination of technical superiority, wide applicability, and proven field performance underscores HORON's position as a trusted partner in advanced fluid management.

Ensuring Trust: Frequently Asked Questions & HORON Guarantees

Understanding the critical need for reliability and support in B2B transactions, HORON is dedicated to providing transparent information and comprehensive customer service for its HORON 25mm PPR Plumbing Pipes. We believe that clarity on product capabilities, delivery, and after-sales support builds lasting trust with our clients. Here are answers to some frequently asked questions and details about our commitment to quality and service.

Frequently Asked Questions (FAQ)

Q1: What are the primary advantages of HORON 25mm PPR Plumbing Pipes over traditional metal pipes?

A1: HORON PPR pipes offer superior corrosion resistance, eliminating issues like rust and scaling. They have a lower thermal conductivity, which reduces heat loss in hot water systems, leading to energy savings. Their smooth inner surface minimizes friction and pressure drop, and they are lightweight, making installation easier and more cost-effective. Furthermore, they boast a longer service life of over 50 years under normal operating conditions.

Q2: What international standards do HORON PPR pipes comply with?

A2: Our HORON 25mm PPR Plumbing Pipes are manufactured in strict compliance with globally recognized standards, including ISO 15874 for hot and cold water installations, and DIN 8077/8078 for PPR pipe dimensions and technical specifications. HORON also holds ISO 9001 and ISO 14001 certifications, reflecting our commitment to quality management and environmental responsibility in our manufacturing processes.

Q3: Can these pipes be used for industrial chemical transportation?

A3: While HORON PPR pipes exhibit excellent resistance to a wide range of chemicals, their suitability for specific industrial chemical transport applications depends on the exact chemical composition, concentration, temperature, and pressure. We recommend consulting our technical team with detailed specifications of the intended fluid for a precise compatibility assessment. Our experts can provide tailored advice and support to ensure optimal system design and material selection.

Delivery and Warranty Commitments

HORON understands the critical nature of timely delivery for large-scale projects. Our streamlined logistics and robust supply chain management ensure efficient processing and dispatch of orders for HORON 25mm PPR Plumbing Pipes. For standard orders, our typical delivery cycle ranges from 10 to 20 business days, depending on order volume and destination. For urgent or large-volume bespoke orders, we work closely with clients to establish expedited schedules, leveraging our extensive production capacity and global distribution network. Each shipment is meticulously packaged to prevent damage during transit, ensuring that products arrive in pristine condition, ready for immediate installation.

We stand by the quality and performance of our products with a comprehensive warranty. HORON provides a 10-year warranty against manufacturing defects for all HORON 25mm PPR Plumbing Pipes and fittings, contingent upon proper storage, handling, and installation according to our guidelines and industry best practices. This warranty underscores our confidence in the durability and longevity of our products, offering peace of mind to our clients. Our dedicated customer support team is available to assist with any technical queries, installation guidance, or after-sales service requirements, ensuring a seamless experience from initial inquiry to long-term operational success. We are committed to fostering enduring partnerships built on trust, quality, and mutual success.

Conclusion: Partnering for Future-Proof Plumbing Solutions

The journey through the capabilities and advantages of HORON 25mm PPR Plumbing Pipes reveals a product that is not just a pipe, but a cornerstone of modern, sustainable infrastructure. From its meticulously controlled manufacturing process, adhering to the highest international standards, to its proven performance in diverse and demanding applications, HORON demonstrates a profound commitment to engineering excellence and client satisfaction. These pipes embody the synergy of advanced material science and practical application, offering unparalleled resistance to corrosion, exceptional thermal performance, and a service life that significantly surpasses conventional plumbing materials. As industries globally pivot towards more energy-efficient and environmentally responsible solutions, PPR pipes, and specifically HORON's offerings, stand at the forefront of this transformation.

For B2B decision-makers, specifying HORON's 25mm PPR solutions translates directly into long-term operational savings, reduced maintenance burden, and enhanced system reliability. Our dedication to rigorous quality control, backed by comprehensive certifications and a robust warranty, provides the assurance necessary for large-scale projects where failure is not an option. Beyond the product itself, HORON prides itself on offering responsive technical support, flexible customization options, and efficient logistics, ensuring that our partners receive not just pipes, but a complete solution tailored to their specific needs. We invite you to explore how HORON's expertise in PPR technology can empower your next project, delivering future-proof plumbing systems that are both high-performing and economically viable.

Authoritative References

- International Organization for Standardization (ISO) – ISO 15874: Plastics piping systems for hot and cold water installations – Polypropylene (PP).

- Deutsches Institut für Normung (DIN) – DIN 8077/8078: Polypropylene (PP) pipes - PP-H 100, PP-B 80, PP-R 80 - Dimensions, technical delivery conditions.

- American Society for Testing and Materials (ASTM) International – ASTM D696: Standard Test Method for Coefficient of Linear Thermal Expansion of Plastics Between -30°C and 30°C with a Vitreous Silica Dilatometer.

- Polymer Science and Technology Journal – Articles on the long-term performance and chemical resistance of polypropylene copolymers.

- Global Market Insights, Inc. – Reports on the global PPR pipe market size, share, and trends.

-

Durable UPVC Column Pipes for Submersible Pumps | Efficient Water Flow

NewsAug.14,2025

-

DN100 PVC Well Casing Pipes - Durable & Corrosion-Resistant

NewsAug.13,2025

-

Flexible 32mm HDPE Pipes in Coil | Durable Water & Gas Lines

NewsAug.12,2025

-

DN50 HDPE Pipes in Coils: Flexible, Durable & Easy Install

NewsAug.11,2025

-

32mm HDPE Pipes in Coil: Durable, Flexible, Easy Install

NewsAug.10,2025