Aug . 10, 2025 04:00 Back to list

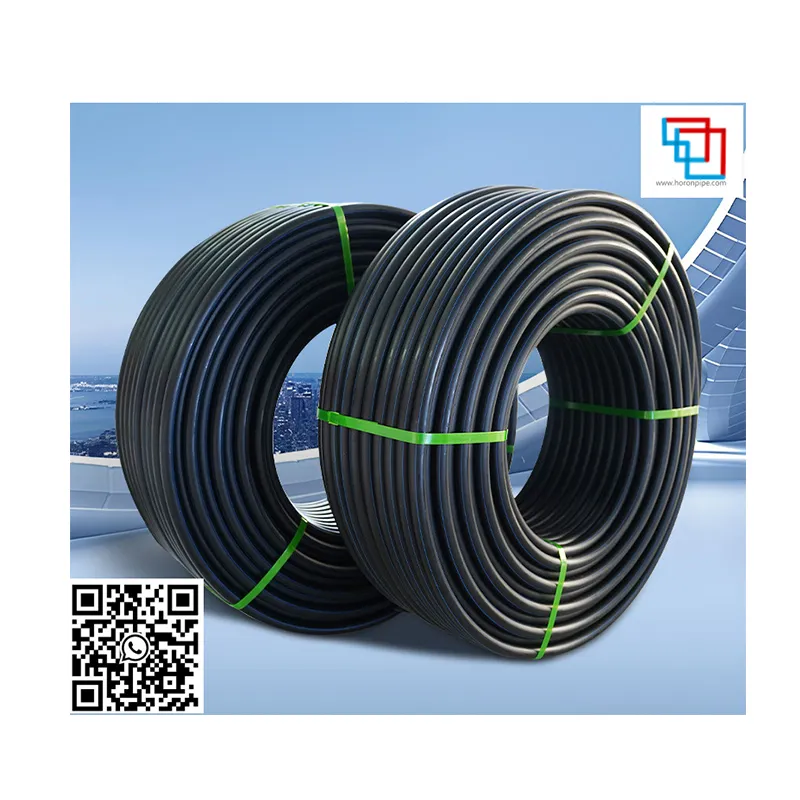

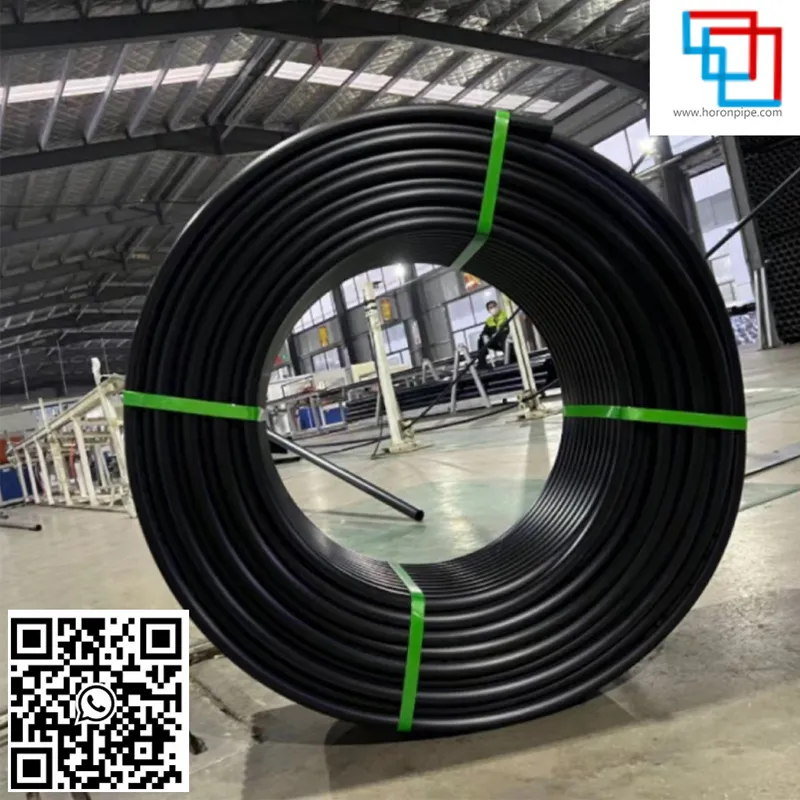

32mm HDPE Pipes in Coil: Durable, Flexible, Easy Install

Navigating the Modern Infrastructure Landscape with 32mm HDPE Pipes in Coil

In the rapidly evolving global infrastructure landscape, the demand for robust, sustainable, and cost-effective piping solutions has never been more critical. Industries ranging from municipal water supply and natural gas distribution to telecommunications and mining are continually seeking advanced materials that can withstand diverse environmental challenges while ensuring long-term operational integrity. High-Density Polyethylene (HDPE) pipes have emerged as a premier choice, fundamentally transforming traditional piping methodologies with their unparalleled attributes. Specifically, the 32mm HDPE Pipes in Coil represent a significant leap forward in this domain, offering a unique combination of flexibility, strength, and ease of installation that sets them apart from conventional rigid piping materials. This specific dimension, 32mm, is particularly versatile, finding extensive application in last-mile connections, specialized industrial processes, and intricate network extensions where larger diameter pipes might be impractical or oversized. The coiled format further enhances their utility, enabling seamless, joint-free installations over extended distances, thereby drastically reducing potential leak points and accelerating project timelines. Industry trends indicate a consistent upward trajectory in HDPE pipe adoption, driven by global initiatives focusing on smart cities, sustainable water management, and the expansion of reliable energy grids. Governments and private enterprises alike are increasingly prioritizing materials that promise not only superior performance but also minimal environmental impact and a lower total cost of ownership over their lifecycle. The inherent benefits of HDPE, such as exceptional corrosion and chemical resistance, fatigue endurance, and superb flow characteristics due to a smooth bore, align perfectly with these modern infrastructure demands. As urban centers expand and rural areas require more sophisticated utility access, the logistical advantages of coiled pipes—including reduced transportation costs and simplified handling on challenging terrains—become even more pronounced. This comprehensive analysis aims to delve into the intricate aspects of 32mm HDPE Pipes in Coil, exploring their manufacturing prowess, technical specifications, diverse applications, and the strategic advantages they offer to B2B decision-makers and technical professionals seeking optimal solutions for their complex projects.

Manufacturing Process Unveiled: From Granules to Coiled Excellence

The production of high-quality 32mm HDPE Pipes in Coil is a sophisticated extrusion process, a stark contrast to traditional metal pipe manufacturing techniques like casting or forging. It begins with the careful selection of premium-grade virgin HDPE resin, typically PE100, renowned for its superior strength, toughness, and long-term performance under pressure. This raw material, in granular form, is fed into an extruder where it is heated to a molten state under precise temperature control. The molten polymer is then pushed through a die, which forms the continuous cylindrical pipe shape. This extrusion phase is critical, ensuring uniform wall thickness and a smooth inner and outer surface, which minimizes friction losses and prevents material buildup during fluid transport. Following extrusion, the nascent pipe enters a vacuum calibration tank, where precise pressure control helps maintain the pipe's exact dimensions (outer diameter and wall thickness) as it cools. Subsequent cooling tanks, often filled with circulating water, solidify the pipe gradually, preventing internal stresses and ensuring structural integrity. Laser or inkjet marking systems then apply essential information such as pipe size, material grade (e.g., PE100), Standard Dimension Ratio (SDR), pressure rating (PN), manufacturing date, and relevant standards (e.g., ISO 4427, EN 12201, ASTM F714) directly onto the pipe surface. This ensures traceability and compliance.

The defining stage for 32mm HDPE Pipes in Coil is the coiling process. Unlike larger diameter pipes that are typically supplied in straight lengths, the 32mm dimension lends itself perfectly to coiling due to its inherent flexibility. After the pipe has sufficiently cooled and solidified, it is precisely guided onto large coiling machines. These machines meticulously wind the continuous pipe into compact coils of specified lengths, commonly 100m, 200m, or even 500m, depending on project requirements and transportation capabilities. This coiling process requires careful tension control to prevent kinking or deformation, ensuring the pipe retains its structural integrity and performance characteristics. Throughout the entire manufacturing process, rigorous quality control measures are implemented at every stage. This includes continuous monitoring of melt temperature, pressure, extrusion speed, and dimensional consistency using advanced in-line measurement systems. Post-production, samples are subjected to stringent laboratory tests, including hydrostatic pressure testing to verify burst strength and long-term pressure resistance, melt flow rate (MFR) testing to ensure material consistency, density checks, tensile strength tests, and impact resistance tests. These comprehensive checks ensure that every meter of 32mm HDPE Pipes in Coil not only meets but often exceeds the most demanding international standards, guaranteeing a service life often exceeding 50 years under proper installation and operating conditions. The robust nature of HDPE, combined with its resistance to corrosion, chemical attack, and abrasion, makes these pipes ideal for critical applications in petrochemical, metallurgical, and municipal water and wastewater systems, where traditional materials often fail prematurely due to aggressive environments or ground movement. Their flexibility also allows them to absorb ground shifts and seismic activity, offering enhanced resilience in dynamic geological zones, thereby contributing significantly to energy efficiency by preventing leaks and maintaining consistent flow.

Technical Parameters & Performance Benchmarks

Understanding the technical parameters of 32mm HDPE Pipes in Coil is paramount for engineers and project managers to ensure optimal system design and long-term performance. The most critical parameter is the Standard Dimension Ratio (SDR), which defines the relationship between the pipe's outer diameter and its wall thickness (SDR = OD / WT). A lower SDR indicates a thicker pipe wall relative to its diameter, translating to a higher pressure rating. For 32mm HDPE pipes, common SDRs include SDR11, SDR13.6, SDR17, and SDR21, corresponding to different pressure nominal (PN) ratings like PN16 (SDR11), PN12.5 (SDR13.6), PN10 (SDR17), and PN8 (SDR21), typically in bars. The specific pressure rating (MOP – Maximum Operating Pressure) determines the pipe's suitability for various fluid transport applications. Material grade, predominantly PE100 for modern high-performance HDPE pipes, signifies a minimum required strength (MRS) of 10 MPa. This classification, along with the slow crack growth resistance (SCGR) and rapid crack propagation (RCP) performance, ensures the pipe's durability and resilience under long-term stress. The melt flow rate (MFR) is another crucial parameter, indicating the ease of melt processing and consistency of the polymer, directly impacting the quality of the finished product and the effectiveness of fusion welding. A consistent MFR ensures reliable jointing, a cornerstone of HDPE pipe systems.

Beyond these structural parameters, the performance benchmarks of 32mm HDPE Pipes in Coil are truly exceptional. Their inherent flexibility allows them to accommodate ground movement, seismic activity, and installation around obstacles without the need for numerous fittings, significantly reducing installation complexity and potential leak points. The superior abrasion resistance of HDPE makes it ideal for conveying abrasive slurries in mining or dredging operations, far outperforming metallic pipes that succumb to wear. Furthermore, HDPE is entirely immune to corrosion, tuberculation, and microbial growth, common issues that plague steel, ductile iron, and concrete pipes, leading to reduced flow capacity and increased maintenance costs over time. This non-corrosive nature ensures consistent flow rates throughout the pipe's projected service life of 50 to 100 years. The pipe's smooth inner surface (Hazen-Williams C factor of 150) minimizes friction, leading to lower pumping costs and improved energy efficiency. When considering long-term operational costs and environmental impact, these pipes offer a superior lifecycle assessment. The table below provides a concise overview of typical specifications for 32mm HDPE pipes, highlighting the critical dimensions and performance ratings that guide material selection for diverse engineering projects. These specifications are rigorously tested and certified against international standards to ensure reliability and compliance across global markets.

Typical Specifications for 32mm HDPE Pipes in Coil (PE100 Grade)

Unmatched Advantages of 32mm HDPE Coils

The adoption of 32mm HDPE Pipes in Coil offers a compelling array of advantages over traditional piping materials, making them an increasingly preferred solution across various sectors. One of the foremost benefits is their exceptional corrosion resistance. Unlike metallic pipes which are prone to rust and degradation from aggressive soils, chemicals, and electrochemical reactions, HDPE pipes remain inert. This eliminates the need for cathodic protection, internal coatings, or special linings, drastically reducing maintenance costs and extending the system's operational lifespan. This intrinsic resistance ensures a consistent flow capacity over decades, as there is no build-up of scale or bio-film (tuberculation) on the smooth inner surface, a common issue in metallic pipes that can significantly reduce hydraulic efficiency. Furthermore, the inherent flexibility of HDPE is a game-changer. The coiled format allows for longer, joint-free runs, reducing the number of fittings required. This flexibility also makes them highly resistant to fatigue from surge pressures and earth movements, including seismic activity and soil subsidence, preventing costly bursts or leaks that can cripple infrastructure. They can be installed using trenchless technologies like horizontal directional drilling (HDD) or pipe bursting, minimizing disruption to surface areas, accelerating project completion, and significantly lowering installation costs compared to open-cut methods.

Another profound advantage is the leak-proof nature of fusion-welded joints. HDPE pipes can be joined by heat fusion (butt fusion or electrofusion), creating a monolithic, homogeneous pipe system that is stronger than the pipe itself. This eliminates the weak points inherent in mechanical joints, such as those found in PVC, ductile iron, or steel pipes, which are susceptible to leaks due to material degradation, improper installation, or ground movement. The integrity of these fusion joints is critical for high-pressure applications and for maintaining the purity of conveyed fluids, whether it's potable water or natural gas. The lightweight nature of 32mm HDPE Pipes in Coil simplifies handling and transportation, reducing labor and equipment costs on site. A coil of 32mm HDPE pipe, even at 500m length, is significantly lighter and easier to manage than equivalent lengths of metallic or rigid plastic pipes. Environmentally, HDPE is a sustainable choice. It is recyclable, consumes less energy in manufacturing compared to other materials like steel, and its long lifespan reduces the frequency of pipe replacement, minimizing resource consumption. Its excellent abrasion resistance makes it ideal for abrasive slurries in mining or conveying applications, where other materials would rapidly erode. The UV stability of modern HDPE compounds ensures performance even when exposed to sunlight, while its resistance to low temperatures means it won't become brittle and crack in freezing conditions, unlike some traditional plastics. These combined attributes contribute to a much lower total cost of ownership (TCO) for projects utilizing 32mm HDPE coils, encompassing reduced installation expenses, minimal maintenance, extended service life, and enhanced operational efficiency.

Comparative Analysis: 32mm HDPE Coils vs. Traditional Pipe Materials

Diverse Applications Across Key Industries

The versatility of 32mm HDPE Pipes in Coil allows for their deployment across a broad spectrum of industries and application scenarios, addressing critical needs where flexibility, chemical resistance, and ease of installation are paramount. In the municipal sector, they are extensively used for potable water distribution, particularly for service connections to individual households or small commercial establishments from the main distribution lines. Their coiled format facilitates rapid installation, especially in congested urban environments or challenging rural terrains, minimizing excavation and road closures. They are also vital for irrigation systems in agriculture, providing durable and leak-proof conduits for water delivery, often laid across uneven fields where their flexibility reduces the need for numerous fittings. Beyond water, these pipes play a crucial role in natural gas distribution for last-mile connections to homes and businesses, due to HDPE's excellent resistance to gas permeation and its ability to be safely fusion welded, ensuring a truly leak-free network crucial for safety and efficiency. The telecommunications industry heavily relies on 32mm HDPE pipes as protective conduits for fiber optic cables. Their smooth interior allows for easy pulling or blowing of cables, protecting sensitive communication infrastructure from physical damage, moisture ingress, and environmental stressors, thereby ensuring uninterrupted connectivity.

Within industrial contexts, 32mm HDPE Pipes in Coil are deployed in process piping for conveying various chemicals, acids, and bases, thanks to HDPE's broad chemical resistance profile, making them suitable for petrochemical plants, chemical processing facilities, and wastewater treatment plants. In mining operations, they are used for slurry transport, dewatering, and chemical delivery, where their superior abrasion resistance and durability under harsh conditions prove invaluable. Geothermal heating and cooling systems also leverage 32mm HDPE pipes for ground source heat loops, benefiting from HDPE's excellent thermal conductivity, resistance to corrosive soil conditions, and long-term stability. The ability to install long, continuous lengths without joints is particularly advantageous for these deep-bore installations, reducing the risk of leaks over the system's extended lifespan. Furthermore, in specialized applications like landfill gas collection systems, leachate collection, and even in some forms of small-scale hydropower projects, the robustness and inert nature of 32mm HDPE pipes make them a reliable choice. The ease of fusion welding for these smaller diameters, often achievable with portable electrofusion units, further enhances their utility in remote or challenging construction sites. This wide array of applications underscores the adaptability and superior engineering properties that make 32mm HDPE coils a preferred material for discerning B2B clients seeking reliable and efficient fluid and gas conveyance solutions.

Ensuring Quality: Testing, Certifications, and Compliance

The unwavering commitment to quality is fundamental in the production of 32mm HDPE Pipes in Coil, ensuring that each product meets stringent performance and safety criteria. This commitment is upheld through a multi-faceted approach involving rigorous testing, adherence to international standards, and third-party certifications. Post-manufacturing, pipe samples undergo a battery of physical and mechanical tests. Hydrostatic pressure testing is paramount, where pipe sections are subjected to internal pressure significantly higher than their rated operating pressure for extended periods (e.g., 100 hours or even 1000 hours), simulating long-term stress. This test confirms the pipe's ability to withstand sustained internal pressure without yielding or bursting, validating its pressure rating and long-term hydrostatic strength (LTHS). Melt Flow Rate (MFR) testing, performed according to ISO 1133 or ASTM D1238, assesses the consistency of the polymer's flow properties, which is crucial for uniform extrusion and reliable fusion welding. Deviations in MFR can indicate inconsistent material quality or processing issues. Density testing (ISO 1183) confirms the material's grade, ensuring it corresponds to the specified PE100 or PE80 classification, directly impacting mechanical properties.

Further essential tests for 32mm HDPE Pipes in Coil include tensile strength and elongation at break (ISO 527), which measure the pipe's resistance to stretching and its ductility, vital for flexibility and resilience against external forces. Impact resistance tests, such as Charpy or Izod (ISO 179/180), evaluate the pipe's ability to absorb energy before fracturing, particularly important for handling during cold weather installations or resistance to sudden impacts. Slow Crack Growth Resistance (SCGR) tests (e.g., notched constant tensile load - NCTL, or full notch creep test - FNCT) are performed to predict the long-term resistance of HDPE pipes to brittle fracture initiated by small defects or stress concentrations, a critical factor for service life. Rapid Crack Propagation (RCP) tests (e.g., S4 test) assess the material's resistance to sudden, fast-moving cracks under pressure, ensuring containment integrity. Beyond these physical tests, reputable manufacturers adhere to comprehensive quality management systems, typically certified to ISO 9001. This certification ensures that all processes, from raw material procurement and manufacturing to testing and delivery, follow documented procedures for consistent quality. Product-specific certifications from independent bodies like NSF (for potable water), KIWA, WRAS, or national standards organizations (e.g., British Standards, DIN, ASTM) provide additional assurance of compliance with relevant industry regulations and health standards, reinforcing the product's authority and trustworthiness in the market. This meticulous approach to quality control and certification is what differentiates a high-performance 32mm HDPE Pipes in Coil from lesser alternatives, providing B2B clients with peace of mind regarding project longevity and system reliability.

Custom Solutions & Engineering Support

While standard 32mm HDPE Pipes in Coil offer exceptional versatility, many large-scale B2B projects often require tailored solutions to meet specific, unique engineering challenges. A leading manufacturer understands that a one-size-fits-all approach is rarely sufficient for complex infrastructure developments. Therefore, offering comprehensive custom solutions and robust engineering support becomes a distinguishing factor. Customization options for 32mm HDPE pipes can include varying coil lengths beyond standard offerings, optimizing for project-specific installation runs and minimizing waste. While the diameter remains fixed at 32mm, customers might require specific SDRs or pressure ratings (PN) that are not commonly stocked but are critical for their unique operating conditions or regulatory compliance in a particular region. Color customization, beyond the standard black (for UV resistance) or black with blue stripes (for potable water), might be requested for specific applications like gas lines (yellow stripe) or reclaimed water (purple stripe) for clear identification in complex utility corridors. Special formulations of HDPE, perhaps with enhanced UV stabilizers for above-ground applications in extremely sunny climates, or compounds with improved resistance to specific industrial chemicals, can also be developed to address highly specialized requirements.

Beyond physical product customization, the provision of expert engineering support is invaluable. This support typically commences during the project planning and design phase, where experienced engineers can provide detailed technical consultations. This includes assisting clients with hydraulic calculations, pressure drop analysis, surge analysis, and thermal expansion considerations unique to HDPE pipes. They can also advise on optimal pipe selection (SDR, material grade) based on specific fluid properties, flow rates, operating temperatures, and ground conditions. For trenchless installation methods like horizontal directional drilling (HDD) or pipe bursting, specialized engineering guidance is crucial to ensure proper pull forces are calculated and pipe integrity is maintained during installation. Support extends to providing comprehensive fusion welding guidelines, training, and troubleshooting, ensuring that joints are created to the highest standards, preserving the monolithic nature of the HDPE system. For instance, a client undertaking a complex water network expansion in a seismic zone might require a detailed analysis of the 32mm HDPE Pipes in Coil's flexibility and seismic performance, along with recommendations for anchoring and bedding. Such tailored expertise and responsive technical assistance not only optimize system performance and longevity but also build significant trust and confidence with B2B decision-makers, solidifying the manufacturer's position as a reliable and authoritative partner in critical infrastructure projects. This collaborative approach ensures that the chosen 32mm HDPE pipe solution is precisely aligned with the project's unique demands, delivering maximum value and operational efficiency.

Real-World Impact: Application Case Studies & Client Success

The theoretical advantages of 32mm HDPE Pipes in Coil are best exemplified through real-world application case studies and validated by direct client feedback, showcasing their tangible impact on project success and operational efficiency. One notable example involves a challenging municipal water service line upgrade project in a densely populated urban area. The existing aged metallic service lines were prone to frequent leaks, causing significant water loss and continuous maintenance burden. The conventional method of open-trench replacement would have resulted in severe traffic disruptions and prolonged construction times. By utilizing 32mm HDPE pipes in long coiled lengths, combined with trenchless horizontal directional drilling (HDD) technology, the installation was streamlined. A single coil of 200 meters could replace multiple rigid pipe sections, drastically reducing the number of fusion joints required and accelerating installation by over 50%. The pipe's flexibility allowed it to navigate existing underground utilities without extensive excavation. Post-installation, the leak rate was virtually eliminated, and the operational pressure was maintained consistently, leading to significant water savings and improved service reliability for residents. Client feedback highlighted the minimal surface disruption and the overall cost-effectiveness of the HDPE solution compared to traditional methods.

Another compelling case study involves a remote agricultural irrigation system expansion. The project site featured undulating terrain and rocky soil, making the transport and installation of rigid pipes logistically challenging and expensive. The lightweight nature and flexibility of 32mm HDPE Pipes in Coil proved decisive. Coils were transported efficiently to the site, even over rough paths, and could be unspooled and laid directly into prepared trenches (or even superficial ditches in some areas) with minimal effort. The fusion welding capability allowed for seamless connections even in challenging field conditions, creating a robust, leak-free network impervious to the corrosive soil and chemical fertilizers used in agriculture. The system's integrity was maintained even with seasonal ground movement, preventing costly repairs and ensuring consistent water delivery for crops. A project manager on this site specifically praised the speed of deployment and the significant reduction in labor hours, which directly contributed to finishing the project ahead of schedule and under budget. Furthermore, a telecommunications provider reported enhanced efficiency in deploying fiber optic networks using 32mm HDPE conduits. The smooth inner bore and continuous lengths facilitated blowing long runs of fiber cables, significantly reducing the need for costly and labor-intensive splice pits, improving signal integrity, and accelerating network rollout across suburban and rural areas. These instances collectively demonstrate that 32mm HDPE pipes, especially in coiled form, are not just a product but a comprehensive solution that delivers tangible benefits in terms of efficiency, cost-savings, longevity, and superior performance in diverse, real-world operational environments, building unwavering trust with discerning clients globally.

Choosing the Right Partner: Manufacturer Comparison Factors

Selecting the appropriate manufacturer for 32mm HDPE Pipes in Coil is a critical decision for B2B procurement and engineering teams, as it directly impacts project success, operational reliability, and long-term cost efficiency. Beyond mere price, several key factors should guide this selection process to ensure a trustworthy and authoritative partnership. First and foremost is the manufacturer's reputation and track record within the industry. A reputable supplier will have a history of successful project deliveries, positive client testimonials, and a strong market presence. This reputation often stems from consistent product quality, adherence to delivery schedules, and reliable after-sales support. Quality control processes are paramount; inquire about their raw material sourcing (preferably virgin PE100 resin from global leaders) and their in-house testing capabilities, including hydrostatic, MFR, density, and impact tests. Manufacturers who invest in state-of-the-art testing laboratories and continuous process monitoring systems demonstrate a genuine commitment to product excellence. Certifications are another vital indicator of quality and compliance. Look for manufacturers holding ISO 9001 (Quality Management System) and relevant product certifications from recognized international bodies such as EN, ASTM, ISO, or national standards authorities like DIN, BS, or AS/NZS. These certifications validate that the pipes meet specific performance criteria and are suitable for intended applications, especially for potable water or gas distribution.

Furthermore, assess the manufacturer's commitment to research and development (R&D). An innovative manufacturer will continually strive to improve product performance, introduce new solutions, and optimize production processes, staying ahead of industry demands and offering cutting-edge 32mm HDPE Pipes in Coil. This includes advancements in material formulations, enhanced UV resistance, or specialized coatings. After-sales service and technical support are equally crucial. A reliable partner offers comprehensive technical assistance, from design consultation and material selection guidance to installation support and troubleshooting. This ensures that any challenges encountered during a project are quickly and expertly addressed, minimizing downtime and costs. Inquire about their typical lead times and logistical capabilities for delivering coiled pipes to your project site, especially for large volumes or international shipments. Companies with robust supply chain management and efficient logistics networks can significantly impact project timelines. Finally, consider their experience with projects similar to yours. A manufacturer with extensive experience in your specific industry (e.g., water utilities, gas distribution, mining) will have a deeper understanding of your unique challenges and regulatory requirements, allowing them to offer more relevant and effective solutions. By thoroughly evaluating these factors, B2B decision-makers can forge a partnership with a manufacturer that not only supplies high-quality 32mm HDPE pipes but also acts as a reliable, authoritative, and trustworthy collaborator throughout the lifecycle of their infrastructure projects. This diligence in selection will translate directly into long-term savings and operational stability, underscoring the importance of due diligence in supplier assessment.

Frequently Asked Questions (FAQ) about 32mm HDPE Pipes in Coil

Q1: What is the typical service life of 32mm HDPE Pipes in Coil?

Under proper design, installation, and operating conditions, 32mm HDPE Pipes in Coil manufactured from PE100 grade material are engineered for an exceptionally long service life, often exceeding 50 to 100 years. This remarkable longevity is attributed to their inherent resistance to corrosion, chemical degradation, abrasion, and fatigue. Unlike metallic pipes that can corrode over time, or some rigid plastics that may become brittle, HDPE maintains its structural integrity and performance characteristics for decades, resulting in a very low total cost of ownership over the product's lifespan. Factors like consistent temperature and pressure, minimal exposure to direct UV (when buried), and the integrity of fusion joints contribute significantly to achieving this extended service life. Regular maintenance is virtually non-existent for buried HDPE pipes, further extending their operational life without intervention.

Q2: How are 32mm HDPE Pipes in Coil joined, and what are the advantages of this method?

32mm HDPE Pipes in Coil are predominantly joined using heat fusion techniques, primarily butt fusion or electrofusion. Butt fusion involves heating the ends of two pipe sections to a molten state using a heated plate, then pressing them together under controlled pressure to form a homogeneous joint. Electrofusion utilizes specialized fittings with embedded electrical coils; passing current through these coils melts the pipe and fitting surfaces, creating a strong, leak-proof bond. The primary advantage of these fusion methods is the creation of a monolithic joint that is as strong as, or even stronger than, the pipe itself. This eliminates the need for mechanical couplings and gaskets, which are common points of failure and leakage in traditional piping systems. The seamless nature of fusion joints provides superior leak integrity, especially critical for gas distribution or potable water applications, and significantly reduces maintenance requirements and water loss over the pipe's lifetime.

Q3: Can 32mm HDPE Pipes in Coil be used for potable water applications?

Absolutely. 32mm HDPE Pipes in Coil are widely recognized and approved for potable water distribution systems globally. Reputable manufacturers ensure that their pipes intended for this application comply with stringent international standards such as ISO 4427, EN 12201, and often have certifications from health and safety organizations like NSF International, WRAS (Water Regulations Advisory Scheme) in the UK, or similar national bodies. These certifications guarantee that the material does not leach harmful substances into the water and meets all health and safety requirements for drinking water conveyance. The smooth inner surface prevents biofilm growth and tuberculation, ensuring water quality is maintained from source to tap, contributing to public health and reducing operational costs associated with cleaning or treating contaminated water.

Q4: Are these pipes suitable for trenchless installation methods?

Yes, 32mm HDPE Pipes in Coil are exceptionally well-suited for various trenchless installation methods, including horizontal directional drilling (HDD), pipe bursting, sliplining, and pipe reaming. Their inherent flexibility, high tensile strength, and abrasion resistance make them ideal for pulling through boreholes or existing deteriorated pipelines with minimal risk of damage. The ability to supply these pipes in long, continuous coiled lengths significantly reduces the number of fusion joints required for trenchless installations, accelerating the project timeline and further enhancing the system's integrity. Trenchless technology minimizes surface disruption, reduces environmental impact, and often lowers overall project costs compared to traditional open-cut methods, particularly in urban areas or sensitive ecological zones.

Q5: What are the environmental benefits of using 32mm HDPE Pipes in Coil?

The use of 32mm HDPE Pipes in Coil offers several significant environmental advantages. Firstly, HDPE is a highly recyclable material, and pipes can be repurposed at the end of their long service life, reducing landfill waste. The manufacturing process of HDPE pipes generally requires less energy compared to steel or ductile iron pipes, leading to a lower carbon footprint. Their lightweight nature reduces fuel consumption during transportation to job sites. Crucially, the leak-free fusion joints prevent water loss in distribution networks, conserving a vital resource and reducing energy expended on treating and pumping lost water. Furthermore, their resistance to corrosion and chemical leaching ensures that they do not contaminate the surrounding soil or water, protecting environmental ecosystems. The long lifespan also means fewer replacements and less disruption to the environment over time, contributing to overall sustainability in infrastructure development.

Logistics, Delivery, and Warranty Commitments

For B2B clients, the efficiency of logistics, transparency in delivery cycles, and the assurance of robust warranty commitments are as crucial as the product quality itself. A reputable manufacturer of 32mm HDPE Pipes in Coil understands that timely and secure delivery is paramount for project scheduling and execution. Logistics for coiled pipes are optimized due to their compact nature, allowing for more linear meters to be transported per truckload compared to straight pipe sections, thereby reducing freight costs and environmental impact. Manufacturers typically offer various shipping options, including domestic and international freight, ensuring pipes can reach even remote project sites efficiently. Transparent delivery cycle communication is key; clients should expect clear lead times from order placement to dispatch and estimated arrival. This involves proactive communication regarding production schedules, shipping updates, and any potential delays, allowing project managers to adjust their timelines accordingly. Reliable manufacturers also maintain strategic warehousing and distribution networks to facilitate quicker deliveries for common specifications and urgent requirements, showcasing their operational experience and readiness to serve diverse client needs across geographies.

Beyond logistics, comprehensive quality assurance and a clear warranty commitment underpin the trustworthiness of a supplier of 32mm HDPE Pipes in Coil. Reputable manufacturers provide a formal product warranty, typically ranging from 10 to 50 years, against manufacturing defects, material failures, and inability to maintain pressure ratings under specified conditions. This warranty is a testament to the manufacturer's confidence in their product's durability and performance, offering financial protection and peace of mind to clients. It is crucial for clients to understand the terms and conditions of the warranty, including proper installation guidelines, material handling, and acceptable operating parameters. In addition to the product warranty, a strong customer support framework is essential. This includes dedicated account managers, technical support teams accessible for post-delivery queries, and a clear process for addressing any product-related issues or claims. An experienced manufacturer will also provide essential documentation, such as material test reports, quality control certificates, and compliance declarations, verifying that each batch of 32mm HDPE Pipes in Coil meets the promised specifications and international standards. This holistic approach, encompassing efficient logistics, transparent delivery, comprehensive quality assurance, and robust warranty commitments, empowers B2B clients to confidently integrate 32mm HDPE pipes into their critical infrastructure projects, knowing they are partnered with a reliable and committed supplier.

Conclusion & Future Outlook

In summary, the 32mm HDPE Pipes in Coil stand as a testament to modern material science and engineering, offering a confluence of benefits that make them an indispensable asset for contemporary infrastructure development. Their superior flexibility, corrosion resistance, leak-proof fusion joints, exceptional longevity, and ease of installation collectively position them as a highly cost-effective and sustainable alternative to traditional piping materials. From enhancing the reliability of municipal water networks and critical gas distribution lines to safeguarding vital telecommunications infrastructure and facilitating efficient industrial processes, the versatility and performance of 32mm HDPE coils address a myriad of complex challenges faced by B2B decision-makers and technical experts. The detailed manufacturing process, coupled with rigorous testing and adherence to international standards, ensures a product that consistently delivers on its promise of durability and efficiency. As global demands for resilient, eco-friendly, and economically viable infrastructure solutions continue to escalate, the adoption of HDPE piping, particularly in convenient coiled formats like the 32mm variant, is poised for sustained growth.

The future outlook for 32mm HDPE Pipes in Coil is exceedingly promising, driven by ongoing innovations in material science and increasing emphasis on sustainable development goals. Research and development continue to explore enhanced HDPE grades with even greater resistance to extreme temperatures, higher pressures, and specialized chemical compounds, broadening their application spectrum. Advancements in intelligent piping systems, including integrated sensors for leak detection and flow monitoring, will further enhance the value proposition of HDPE networks. Furthermore, the global trend towards smart city initiatives and the modernization of aging utility infrastructure will continue to fuel the demand for reliable, long-lasting, and easily deployable piping solutions that minimize environmental impact and operational expenditures. Manufacturers committed to quality, innovation, and comprehensive client support will lead this evolution, solidifying the role of 32mm HDPE pipes as a foundational component for the next generation of global infrastructure. Investing in these pipes is not merely a purchase; it is a strategic decision towards a more resilient, efficient, and sustainable future for critical fluid and gas conveyance systems.

References and Further Reading:

- Plastic Pipe Institute (PPI) – PPI PE Handbook for Water and Wastewater Applications

- ISO 4427-2:2019 - Plastics piping systems for water supply, and for drainage and sewerage under pressure — Polyethylene (PE) — Part 2: Pipes

- ASTM F714 / F714M-20 - Standard Specification for Polyethylene (PE) Plastic Pipe (SDR-PR) Based on Outside Diameter

- International Water Association (IWA) - The role of HDPE pipes in sustainable water management

-

140mm PVC Drilling Pipe: Durable & Efficient Well Casings

NewsAug.09,2025

-

Flexible DN50 HDPE Pipes in Coils: Durable & Easy Install

NewsAug.08,2025

-

DN100 PVC Pipes for Well Casings | Durable & Corrosion-Proof

NewsAug.07,2025

-

Durable DN500 HDPE Double Wall Corrugated Drain Pipes

NewsAug.06,2025

-

32mm HDPE Pipes Coil: Durable & Flexible Water Supply

NewsAug.05,2025