Aug . 12, 2025 02:00 Back to list

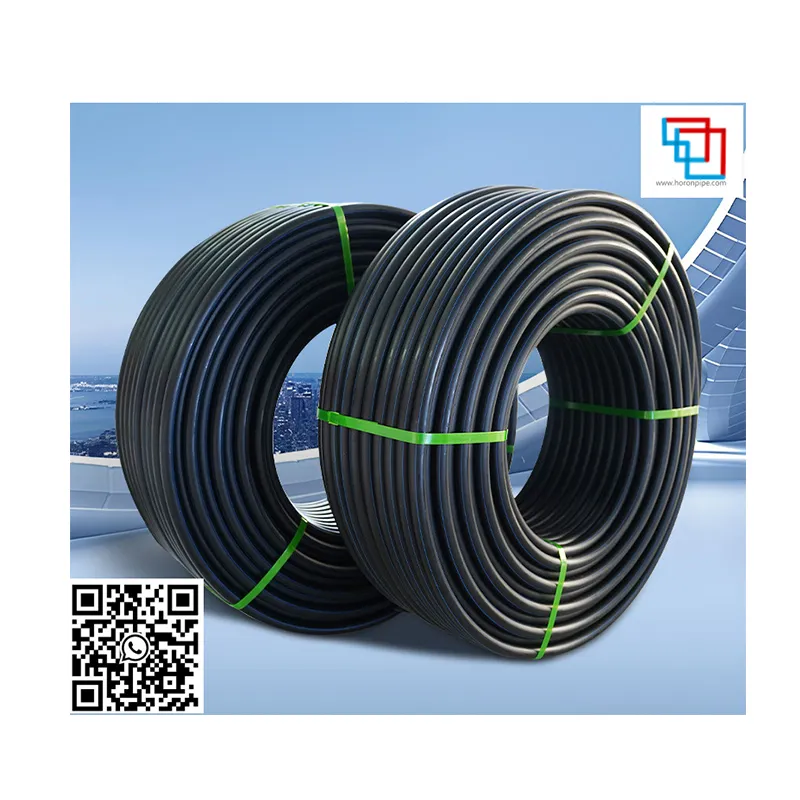

Flexible 32mm HDPE Pipes in Coil | Durable Water & Gas Lines

The Critical Role of 32mm HDPE Pipes in Coil in Modern Infrastructure

In the rapidly evolving landscape of modern infrastructure, the demand for robust, efficient, and cost-effective piping solutions is paramount. Among these, 32mm HDPE Pipes in Coil stand out as a cornerstone for a multitude of applications. High-Density Polyethylene (HDPE) pipes, renowned for their exceptional durability, flexibility, and resistance to harsh environmental conditions, offer an unparalleled advantage over traditional materials like steel or PVC. Their coiled form significantly simplifies transport, reduces installation time, and minimizes the need for numerous joints, thereby enhancing system integrity and reducing potential leak points. This comprehensive guide delves into the technical intricacies, manufacturing excellence, diverse applications, and inherent benefits that position 32mm HDPE pipes as an indispensable component in today's sophisticated engineering projects.

The increasing global focus on sustainable and resilient infrastructure further amplifies the importance of materials like HDPE. With a service life that can extend beyond 50 years, and their inert nature resisting chemical corrosion and biological growth, 32mm HDPE Pipes in Coil contribute significantly to reduced maintenance costs and environmental impact. Understanding the precise specifications, manufacturing processes, and application nuances of these pipes is crucial for engineers, procurement specialists, and project managers aiming to optimize their infrastructure investments. This section sets the stage by highlighting their overarching significance and outlining the in-depth exploration that follows regarding their unparalleled performance and versatility.

Precision Manufacturing: The Process Behind 32mm HDPE Pipes in Coil

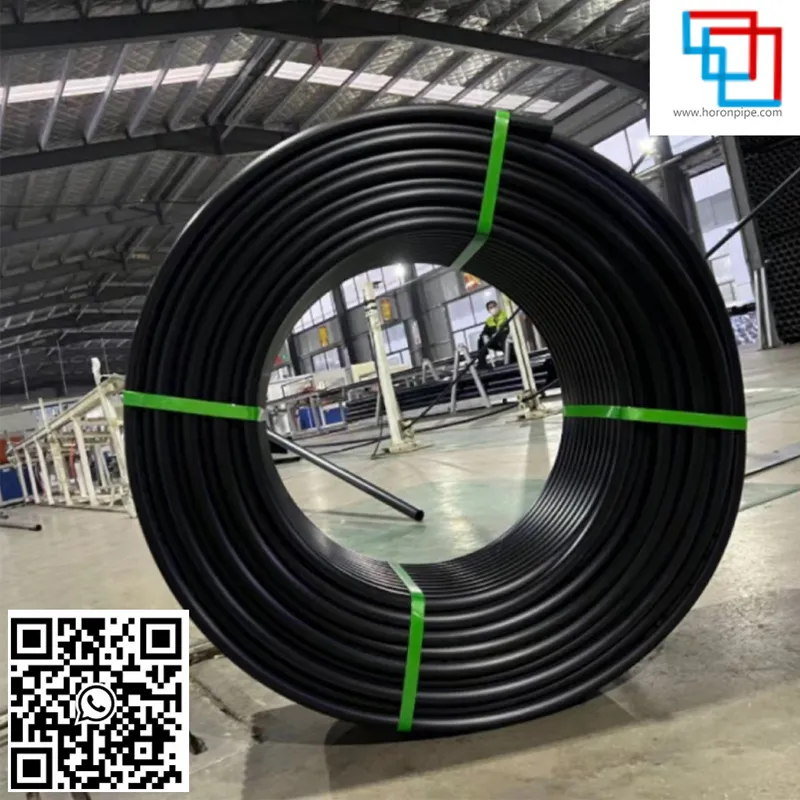

The production of 32mm HDPE Pipes in Coil is a sophisticated extrusion process, ensuring consistent quality and adherence to stringent industry standards. The journey begins with high-grade HDPE resin, typically PE100 or PE80, known for its superior strength-to-density ratio and excellent long-term hydrostatic strength. This resin is fed into an extruder, where it is heated and melted to a homogeneous consistency. The molten polymer is then forced through a die, which precisely forms the pipe's desired 32mm outer diameter and wall thickness. This precision is critical for maintaining consistent pressure ratings and flow characteristics across the pipe's entire length.

Following extrusion, the pipe enters a cooling bath, typically a water tank, where it is gradually cooled to solidify its shape and mechanical properties. The rate of cooling is meticulously controlled to prevent internal stresses and ensure optimal material crystallinity. Post-cooling, the pipe undergoes continuous dimensional and quality checks, including ultrasonic wall thickness measurements, diameter verification, and surface integrity inspection. Compliance with international standards such as ISO 4427, EN 12201, and ASTM F714 is rigorously maintained throughout this stage. The finished pipe is then spooled into large coils, facilitating efficient transportation, handling, and installation on job sites. This coiling process is engineered to prevent kinking or damage to the pipe, ensuring its structural integrity from factory to final application. The manufacturing process is designed for a service life exceeding 50 years under proper conditions.

Key aspects of the manufacturing process ensure the superior performance of 32mm HDPE Pipes in Coil, especially concerning their application in demanding environments like petrochemical, mining, and municipal water supply systems. The inherent flexibility of HDPE, combined with its resistance to slow crack growth (SCG) and rapid crack propagation (RCP), makes it an ideal choice for dynamic or unstable ground conditions. Unlike metallic pipes, HDPE does not corrode, rust, or tuberculate, preventing blockages and maintaining flow efficiency, leading to significant energy savings for pumping systems. This anti-corrosive property is particularly vital in aggressive soil conditions or when transporting corrosive fluids, such as those found in industrial chemical processing or wastewater treatment, significantly extending the system's operational lifespan and reducing maintenance expenditure.

Technical Parameters and Performance Advantages

The superior performance of 32mm HDPE Pipes in Coil is underscored by their comprehensive technical specifications, which dictate their suitability for various demanding applications. Key parameters include the Nominal Outer Diameter (OD), Standard Dimension Ratio (SDR), and Nominal Pressure (PN) rating. For a 32mm pipe, common SDR values are SDR11 (PN16) and SDR17 (PN10), indicating the ratio of pipe diameter to wall thickness, directly influencing its pressure resistance. Manufactured from PE100 material, these pipes exhibit excellent tensile strength, elongation at break, and resistance to creep, ensuring long-term structural integrity under sustained pressure.

Beyond dimensional stability, HDPE pipes offer significant advantages. Their flexibility allows for radius bending without additional fittings, reducing installation complexity and cost, particularly in trenchless applications like horizontal directional drilling (HDD). The smooth internal bore minimizes friction loss, contributing to energy efficiency in fluid transport. Furthermore, HDPE is highly resistant to chemical attack from a wide range of acids, alkalis, and salts, making it suitable for industrial processes, mining, and wastewater applications. The material's non-toxic nature also makes it ideal for potable water supply.

Typical Technical Specifications for 32mm HDPE Pipes in Coil

| Parameter | Value/Description |

|---|---|

| Nominal Outer Diameter (OD) | 32 mm |

| Material Grade | PE100 / PE80 (High-Density Polyethylene) |

| Standard Dimension Ratio (SDR) | SDR11, SDR17, SDR21 (Commonly) |

| Nominal Pressure (PN) Rating | PN16 (for SDR11), PN10 (for SDR17), PN8 (for SDR21) at 20°C |

| Color | Black with blue stripes (for water) or other specified colors |

| Tensile Strength | > 20 MPa (PE100) |

| Elongation at Break | > 350% |

| Fusion Joining Method | Butt Fusion, Electrofusion |

| Working Temperature Range | -40°C to +60°C (with pressure de-rating at higher temperatures) |

| Lifetime Expectancy | 50+ years under ideal conditions |

The coiled format of 32mm HDPE Pipes in Coil is a significant operational advantage, allowing for continuous lengths of pipe to be installed with minimal joints, thus drastically reducing the risk of leaks and improving overall system integrity. This is particularly beneficial for long-distance water supply lines, irrigation systems, or gas distribution networks where continuous runs are preferred. The material's robust resistance to slow crack growth and its inherent flexibility also make it highly resilient to ground movement and seismic activity, offering a reliable solution in geologically active regions.

Diverse Application Scenarios and Industry Trends

The versatility of 32mm HDPE Pipes in Coil extends across a broad spectrum of industries, driven by their adaptability and long-term cost-effectiveness. In the Water Supply and Distribution sector, these pipes are crucial for municipal potable water networks, rural water schemes, and residential connections due to their non-corrosive nature and resistance to bio-fouling, ensuring clean water delivery. Their coiled form is particularly advantageous for last-mile connections and in areas with challenging terrain, minimizing excavation and installation disruption.

For Wastewater and Drainage, HDPE pipes are increasingly preferred for sewage force mains, gravity sewers, and storm drains. Their superior abrasion resistance and chemical inertness make them ideal for handling abrasive slurries and corrosive industrial effluents. In the Mining Industry, they are extensively used for tailings transport, process water, and dewatering applications, enduring harsh operational conditions and chemical exposure. The Agricultural Sector benefits from 32mm HDPE pipes for irrigation systems, including drip irrigation and sprinkler lines, where flexibility and ease of installation over large areas are critical.

The trend towards trenchless installation methods, such as Horizontal Directional Drilling (HDD) and pipe bursting, further boosts the adoption of 32mm HDPE Pipes in Coil. Their flexibility and the strength of their fused joints make them highly suitable for these minimal-disruption techniques, reducing environmental impact and construction time in urban environments. Furthermore, with the growing emphasis on smart infrastructure, HDPE pipes are often integrated with IoT sensors for real-time monitoring of flow, pressure, and leakage, enhancing operational efficiency and predictive maintenance capabilities. This integration positions HDPE as a forward-looking solution for sustainable and intelligent utility networks.

Manufacturer Comparison and Customization Solutions

When selecting 32mm HDPE Pipes in Coil, evaluating manufacturers is crucial. Key differentiating factors include raw material quality, manufacturing precision, adherence to international standards (ISO, ASTM, DIN), and the extent of product customization offered. Reputable manufacturers prioritize the use of virgin PE100 or PE80 resins, ensuring optimal mechanical properties and long-term performance, unlike those who might incorporate recycled materials that compromise durability. Precision in extrusion, monitored through advanced quality control systems, guarantees uniform wall thickness and consistent dimensional accuracy, which is vital for effective fusion welding and reliable system operation.

A comparison might highlight that while some manufacturers offer standard SDR ratings and coil lengths, leading suppliers like Horon Pipe differentiate themselves through comprehensive customization capabilities. This includes tailoring pipe lengths within coils to minimize waste on specific project sites, offering unique color coding for different applications (e.g., blue for potable water, yellow for gas), and providing specialized co-extruded layers for enhanced UV resistance or barrier properties in demanding environments. Furthermore, leading manufacturers offer pipes with specific certifications for different regions (e.g., WRAS for UK, DVGW for Germany) demonstrating their commitment to global quality benchmarks.

Key Factors in Manufacturer Comparison

- Raw Material Sourcing: Verifying the use of virgin, high-grade PE100/PE80 resins from certified suppliers.

- Quality Control & Certifications: Adherence to ISO 9001 for quality management, alongside product-specific standards like ISO 4427.

- Production Capacity & Lead Time: Ability to meet large-scale project demands and deliver efficiently.

- Customization Options: Flexibility in SDR, PN rating, color, coil length, and specialized additives.

- Technical Support & After-Sales Service: Availability of engineering support, training, and warranty provisions.

- Project Experience: A proven track record of successful installations in similar applications globally.

Customization extends beyond physical pipe characteristics to logistical solutions, such as specific packaging and delivery schedules, which can significantly impact project timelines and costs. Manufacturers that provide dedicated technical consultation from design to installation ensure that the chosen 32mm HDPE Pipes in Coil solution perfectly matches the unique demands of each infrastructure project, optimizing both performance and return on investment.

Ensuring Quality: Certifications, Support, and Warranty

The integrity and reliability of 32mm HDPE Pipes in Coil are fundamentally guaranteed by adherence to rigorous quality standards and comprehensive support systems. Reputable manufacturers, such as Horon Pipe, commit to international certifications like ISO 9001:2015 for quality management, ensuring that every stage from raw material procurement to final product inspection meets stringent criteria. Product-specific certifications, including ISO 4427 for polyethylene piping systems for water supply and EN 12201, validate the pipe's performance characteristics and suitability for intended applications. Further, compliance with regional approvals such as WRAS (Water Regulations Advisory Scheme) or DVGW (German Technical and Scientific Association for Gas and Water) signifies eligibility for use in specific national water supply networks.

Beyond certifications, trustworthiness is built through transparent customer support and robust warranty offerings. A dedicated technical support team capable of assisting with project design, material selection, and installation best practices is invaluable. This includes providing detailed engineering data, hydrostatic testing reports, and guidance on fusion welding techniques specific to 32mm HDPE Pipes in Coil. For instance, high-quality manufacturers can provide creep rupture strength data derived from long-term tests at elevated temperatures, proving material durability.

Typical delivery cycles for standard orders range from 2 to 4 weeks, with expedited options available for urgent projects, dependent on order volume and customization. Manufacturers also provide clear warranty statements, often covering material defects and workmanship for periods ranging from 10 to 15 years, underscoring their confidence in product longevity. This commitment to quality assurance, coupled with responsive customer service and comprehensive warranties, provides project managers and engineers with the confidence needed for critical infrastructure investments.

Frequently Asked Questions (FAQ) about 32mm HDPE Pipes in Coil

-

Q1: What are the primary advantages of using 32mm HDPE Pipes in Coil over PVC or metallic pipes?

A1: HDPE pipes offer superior flexibility, allowing for fewer joints and easier installation, especially in challenging terrains. They are highly resistant to corrosion, abrasion, and chemical attack, ensuring a much longer service life (50+ years). Unlike metallic pipes, they don't rust or scale, maintaining flow efficiency. They are also lighter, simplifying transport and handling.

-

Q2: How is the service life of 32mm HDPE Pipes in Coil calculated, and what factors influence it?

A2: The service life is determined by factors like material grade (PE100 offers superior longevity), operating temperature, internal pressure, and the specific application's chemical environment. Manufacturers use long-term hydrostatic strength tests (creep rupture tests) to predict performance over decades. A minimum of 50 years is a common design life under standard conditions.

-

Q3: Can 32mm HDPE Pipes in Coil be used for potable water supply?

A3: Yes, high-quality HDPE pipes made from virgin resin are non-toxic and tasteless, making them ideal for potable water applications. They do not leach chemicals into the water and resist biological growth. Always ensure the pipes comply with relevant potable water certifications like WRAS or NSF.

-

Q4: What joining methods are recommended for 32mm HDPE Pipes in Coil?

A4: The most common and reliable joining methods are heat fusion techniques: butt fusion for larger diameters and electrofusion for fittings and smaller diameters. These methods create monolithic, leak-proof joints that are as strong as the pipe itself. Mechanical fittings are also available but generally less preferred for critical pressure applications.

-

Q5: How do temperature fluctuations affect the performance of HDPE pipes?

A5: HDPE pipes can operate effectively over a broad temperature range (-40°C to +60°C). However, their pressure rating must be de-rated at higher temperatures, as the material's strength decreases with increasing heat. It's crucial to consult pressure de-rating tables provided by the manufacturer based on specific pipe SDR and material grade.

Conclusion: The Future of 32mm HDPE Pipes in Coil

The advent of 32mm HDPE Pipes in Coil represents a significant leap forward in piping technology, addressing critical infrastructure needs with unmatched durability, flexibility, and cost-efficiency. From municipal water distribution to complex industrial applications and agricultural irrigation, their inherent resistance to corrosion, abrasion, and chemical degradation ensures a prolonged service life, minimizing maintenance and replacement costs. The coiled format further enhances their appeal by simplifying logistics and accelerating installation, particularly in challenging environments or for long-distance projects.

As global infrastructure demands continue to grow, driven by urbanization and the necessity for sustainable solutions, the role of HDPE piping will only expand. The commitment of leading manufacturers to rigorous quality control, adherence to international standards, and continuous innovation in material science and production processes solidifies the position of 32mm HDPE Pipes in Coil as a reliable, high-performance solution for the next generation of infrastructure development. Investing in these pipes means investing in resilience, efficiency, and a sustainable future.

References

- ISO 4427: Plastics piping systems for water supply, and for drainage and sewerage under pressure - Polyethylene (PE) - Part 1 to 5.

- EN 12201: Plastics piping systems for water supply, and for drainage and sewerage under pressure - Polyethylene (PE) - Part 1 to 5.

- ASTM F714: Standard Specification for Polyethylene (PE) Plastic Pipe (SDR-PR) Based on Outside Diameter.

- American Water Works Association (AWWA) M55: PE Pipe - Design and Installation.

- Plastics Pipe Institute (PPI) Handbook of Polyethylene Pipe.

-

DN100 PVC Well Casing Pipes - Durable & Corrosion-Resistant

NewsAug.13,2025

-

DN50 HDPE Pipes in Coils: Flexible, Durable & Easy Install

NewsAug.11,2025

-

32mm HDPE Pipes in Coil: Durable, Flexible, Easy Install

NewsAug.10,2025

-

140mm PVC Drilling Pipe: Durable & Efficient Well Casings

NewsAug.09,2025

-

Flexible DN50 HDPE Pipes in Coils: Durable & Easy Install

NewsAug.08,2025