Aug . 19, 2025 02:20 Back to list

32mm HDPE Pipes in Coil: Flexible & Durable Water Supply

Unveiling the Versatility of 32mm HDPE Pipes in Coil for Modern Infrastructure

In the rapidly evolving landscape of industrial and civil infrastructure, the demand for robust, flexible, and efficient piping solutions is paramount. 32mm HDPE Pipes in Coil represent a significant advancement in this regard, offering unparalleled performance for a diverse array of applications. High-Density Polyethylene (HDPE) is a thermoplastic polymer celebrated for its high strength-to-density ratio, making it an ideal material for pipe manufacturing. The coiled format of these pipes further enhances their utility, simplifying logistics, reducing installation time, and minimizing the need for costly jointing processes in the field. This section delves into the intrinsic properties that make 32mm HDPE pipes a preferred choice, exploring their superior corrosion resistance, exceptional flexibility, and long-term durability that extends well beyond traditional piping materials. Understanding these foundational aspects is crucial for stakeholders evaluating material selection for critical infrastructure projects, from potable water supply to advanced telecommunication conduits.

The inherent chemical inertness of 32mm HDPE Pipes in Coil ensures they are immune to galvanic corrosion, tuberculation, and microbial induced corrosion, issues that frequently plague metallic piping systems. This resistance guarantees the purity of conveyed fluids, whether it's potable water for municipal supply or sensitive chemicals in industrial processes. Furthermore, the flexibility of HDPE allows these pipes to be laid following contours of terrain, navigating obstacles without the need for numerous fittings or extensive trenching. This characteristic is particularly beneficial in challenging environments or for trenchless installation methods like horizontal directional drilling (HDD). With a projected service life exceeding 50 years under standard operating conditions, these pipes offer a low-maintenance, high-return investment, significantly reducing total lifecycle costs compared to conventional alternatives. The 32mm diameter is optimally sized for numerous small to medium-scale distribution networks, ensuring efficient flow rates for various fluid and gas transport applications.

The Meticulous Manufacturing Process of 32mm HDPE Pipes

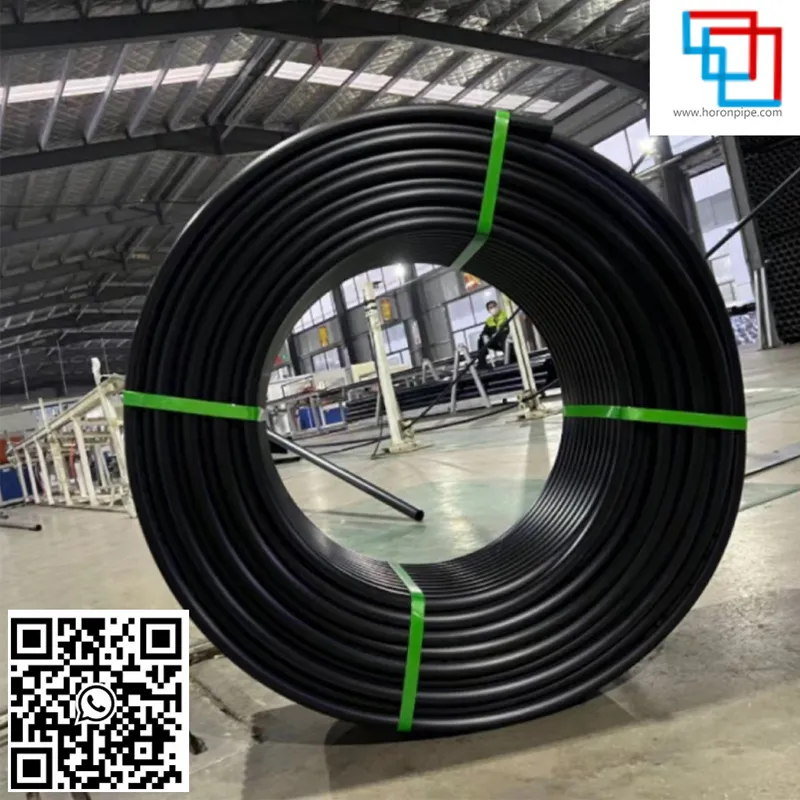

The production of 32mm HDPE Pipes in Coil is a highly sophisticated extrusion process, beginning with high-grade virgin HDPE resin pellets, typically PE100 or PE80, known for their enhanced pressure resistance and long-term performance. The journey starts by feeding these carefully selected raw materials into an extruder, where they are melted under precise temperature controls and homogenized into a molten state. This molten polymer is then pushed through a specialized die that shapes it into the desired 32mm pipe diameter. Following extrusion, the nascent pipe enters a vacuum calibration tank, where external pressure and cooling water ensure the pipe maintains its precise circularity and wall thickness while solidifying. Subsequent cooling baths further solidify the pipe, preparing it for the final stages of production. This meticulous control over temperature and pressure throughout the extrusion line is critical in ensuring the pipe's dimensional stability, smooth internal surface, and consistent mechanical properties, which are paramount for optimal fluid flow and long-term performance.

Quality assurance is an integral part of the manufacturing of 32mm HDPE Pipes in Coil. Post-extrusion, each pipe undergoes rigorous testing to comply with international standards such as ISO 4427, EN 12201, and ASTM F714. These tests include hydrostatic pressure testing to verify resistance to internal pressure, melt flow rate (MFR) testing to confirm material consistency, and tensile strength tests to assess mechanical integrity. Furthermore, specific attention is paid to the pipe's surface finish, uniformity of wall thickness, and overall concentricity to prevent weak points and ensure a smooth flow path. The pipe is then precisely coiled onto drums or reels, often in lengths of 50m, 100m, 200m, or even 500m, depending on project requirements. This coiling process is carefully managed to prevent kinking or stress accumulation within the pipe structure. The comprehensive quality control framework employed throughout the manufacturing process guarantees that each length of 32mm HDPE pipe meets stringent industry benchmarks, providing end-users with a product of superior reliability and a projected service life exceeding 50 years.

Technical Specifications & Performance Data for 32mm HDPE Pipes

The performance characteristics of 32mm HDPE Pipes in Coil are defined by a set of critical technical specifications, which are essential for engineers and project managers to consider during system design. Key parameters include the pipe's outer diameter (OD), wall thickness (WT), Standard Dimension Ratio (SDR), and nominal pressure (PN) rating. The SDR value, calculated as the ratio of OD to WT, directly dictates the pipe's pressure capability; a lower SDR (e.g., SDR11) indicates a thicker wall and higher pressure rating (PN16), while a higher SDR (e.g., SDR17) signifies a thinner wall suitable for lower pressure applications (PN10). Material grades, typically PE100, offer enhanced long-term hydrostatic strength compared to older grades like PE80, ensuring robust performance over a 50-year design life. Furthermore, the material's excellent abrasion resistance makes these pipes suitable for conveying abrasive slurries, and their ductility ensures resistance to fatigue from surge pressures, contributing to their exceptional reliability in diverse operational environments.

Below is a comprehensive table outlining typical technical specifications for 32mm HDPE Pipes in Coil, providing a quick reference for design and procurement teams. This data reflects general industry standards and can vary slightly between manufacturers based on specific product lines and regional certifications.

The performance data tabulated above highlights the robust nature of 32mm HDPE Pipes in Coil. Their superior resistance to slow crack growth (SCG) and rapid crack propagation (RCP) under various stress conditions ensures long-term integrity, even in dynamic environments. The exceptional abrasion resistance of HDPE also makes these pipes ideal for abrasive slurries and mining applications, where traditional materials would quickly degrade. Furthermore, the material's very low thermal conductivity helps maintain fluid temperature, reducing energy losses in heating or cooling applications. These combined attributes, supported by extensive testing and adherence to international standards, position 32mm HDPE pipes as a reliable and economically sound choice for critical infrastructure projects demanding high performance and longevity.

Diverse Applications & Real-World Scenarios for 32mm HDPE Pipes

The adaptability and robust performance of 32mm HDPE Pipes in Coil make them indispensable across a multitude of industries and real-world applications. In the municipal sector, they are extensively used for potable water distribution networks, last-mile connections, and service lines due to their non-corrosive nature and ability to maintain water quality. Their flexibility allows for easy installation in congested urban environments or undulating terrains without extensive earthworks, significantly reducing project timelines and costs. Furthermore, in agricultural settings, these pipes are crucial for irrigation systems, providing efficient and leak-free conveyance of water over long distances, adapting seamlessly to varying field contours. The inherent resistance to UV radiation and harsh environmental conditions ensures a prolonged service life, even when exposed to direct sunlight or buried in aggressive soils. This broad applicability underscores their value as a versatile piping solution for both critical and auxiliary infrastructure development.

Beyond water management, 32mm HDPE Pipes in Coil find critical roles in other sectors. In telecommunications, they serve as protective conduits for fiber optic cables, safeguarding vital data infrastructure from mechanical damage and environmental ingress. Their smooth internal bore facilitates easy cable pulling, reducing installation friction and effort. The mining and industrial sectors also benefit from their resilience; these pipes are used for conveying process water, tailings, and even low-pressure gas, showcasing their chemical resistance and durability against abrasive media. For instance, in a recent remote mining operation in Western Australia, coiled 32mm HDPE pipelines were deployed for dewatering, drastically cutting down installation time by 60% compared to traditional rigid pipe systems, and eliminating nearly 80% of fusion joints, which are typical points of failure. This real-world application exemplifies the significant operational efficiencies and cost savings that these flexible piping solutions deliver, establishing them as a preferred choice for challenging and expansive projects requiring reliability and ease of deployment.

Partnering for Success: Custom Solutions & Manufacturer Expertise

Selecting the right manufacturer for 32mm HDPE Pipes in Coil is critical to ensuring project success and long-term system integrity. A reputable manufacturer differentiates itself not only through adherence to global standards like ISO 9001 for quality management but also through extensive industry experience and a commitment to customer support. Our firm, with over 15 years in the HDPE piping sector, has consistently delivered certified products tailored to specific project demands. We offer comprehensive pre-sales consultation, assisting clients in selecting the optimal pipe specifications (SDR, pressure rating, coil length) for their unique applications, whether it's for municipal water supply, industrial fluid transfer, or specialized infrastructure projects. Our technical team provides expert guidance on material compatibility, installation best practices, and fusion welding techniques, ensuring that the piping system performs as intended throughout its extensive service life. This dedication to expertise and client engagement fosters a partnership approach, moving beyond mere product supply to true solution provision.

Beyond standard offerings, we specialize in providing customized solutions for 32mm HDPE Pipes in Coil, including custom coil lengths, specialized color coding for different applications (e.g., blue for water, yellow for gas), and bespoke marking to meet project-specific traceability requirements. Our robust supply chain and efficient logistics ensure prompt and reliable delivery, even for large-scale international projects, with typical lead times ranging from 2-4 weeks depending on order volume and customization. We stand by the quality of our products with a comprehensive 10-year warranty against manufacturing defects, underscoring our confidence in their durability and performance. Furthermore, our dedicated after-sales support team is available for technical assistance, troubleshooting, and training on installation techniques, ensuring maximum value and minimizing potential downtimes. This end-to-end service commitment, combined with our proven track record with major infrastructure developers and utility companies worldwide, establishes us as a trusted and authoritative partner in the HDPE piping industry.

Frequently Asked Questions (FAQs) about 32mm HDPE Pipes in Coil

Q1: What are the primary advantages of using 32mm HDPE Pipes in Coil over traditional rigid pipes?

A1: The coiled format significantly reduces the number of joints required for installation, minimizing potential leak points and installation time. HDPE pipes themselves offer superior flexibility, corrosion resistance, excellent flow characteristics, and a longer service life (typically 50+ years), leading to lower overall lifecycle costs compared to materials like steel or PVC. Their lighter weight also simplifies transportation and handling.

Q2: What pressure ratings are available for 32mm HDPE pipes, and how does SDR relate to this?

A2: 32mm HDPE pipes are available in various pressure ratings, commonly denoted as PN (Nominal Pressure) values. These ratings are directly tied to the pipe's Standard Dimension Ratio (SDR), which is the ratio of the outer diameter to the wall thickness. A lower SDR (e.g., SDR11) indicates a thicker pipe wall relative to its diameter, resulting in a higher pressure rating (e.g., PN16). Conversely, a higher SDR (e.g., SDR17) means a thinner wall and a lower pressure rating (e.g., PN10). Selecting the correct SDR is crucial for the intended application's pressure requirements.

Q3: Can 32mm HDPE pipes be used for potable water applications?

A3: Yes, absolutely. 32mm HDPE pipes manufactured from virgin PE100 or PE80 material are widely approved for potable water distribution. They do not leach harmful chemicals into the water, are resistant to biological growth, and maintain water quality. Reputable manufacturers adhere to international standards such as NSF/ANSI 61 and national certifications to ensure their suitability for drinking water systems.

Q4: What is the typical delivery period for a large order of 32mm HDPE Pipes in Coil?

A4: For standard specifications and coil lengths, the typical delivery period ranges from 2 to 4 weeks, depending on the order volume, current production schedule, and destination. For highly customized orders or exceptionally large quantities, a more precise lead time will be provided upon order confirmation, often extending slightly to accommodate specialized production. Expedited options may be available depending on urgency and capacity.

Q5: What kind of warranty or after-sales support is offered for these pipes?

A5: We typically offer a comprehensive 10-year warranty against manufacturing defects for our 32mm HDPE Pipes in Coil, reflecting our commitment to quality and durability. Beyond the warranty, our dedicated after-sales support team provides technical assistance for installation, troubleshooting, and general product inquiries. We also offer training sessions for fusion welding techniques to ensure proper installation and maximize the pipe system's lifespan.

Concluding Insights & Future Outlook

The deployment of 32mm HDPE Pipes in Coil offers a compelling blend of technical superiority, economic efficiency, and environmental sustainability for a multitude of modern infrastructure challenges. Their inherent resistance to corrosion, exceptional flexibility, and long design life of over 50 years significantly reduce maintenance burdens and operational costs, providing a substantial return on investment for project developers and utility providers alike. The coiled format dramatically streamlines installation, minimizes jointing requirements, and reduces logistical complexities, particularly advantageous in large-scale linear projects or remote terrains. As the global push towards sustainable infrastructure intensifies, the low carbon footprint associated with HDPE pipe manufacturing and its recyclability further cement its position as a preferred material for environmentally conscious projects.

Looking ahead, the demand for high-performance flexible piping solutions like 32mm HDPE Pipes in Coil is poised for continued growth, driven by urban expansion, climate change adaptation efforts requiring resilient water networks, and the proliferation of smart infrastructure initiatives. Innovations in HDPE material science, such as enhanced crack resistance and higher pressure capabilities, will further expand their application scope. Partnering with a manufacturer that possesses deep technical expertise, adheres to rigorous quality standards, and offers comprehensive support—from initial consultation to after-sales service—is paramount to leveraging the full potential of these advanced piping systems. By prioritizing quality, expertise, and customer-centric solutions, we ensure that our HDPE pipes contribute to building robust, efficient, and sustainable infrastructure for generations to come.

Authoritative References

- ISO 4427:2019, Plastics piping systems for water supply, and for drainage and sewerage under pressure - Polyethylene (PE) - Part 1: General.

- EN 12201:2011, Plastics piping systems for water supply, and for drainage and sewerage under pressure - Polyethylene (PE).

- ASTM F714-19, Standard Specification for Polyethylene (PE) Plastic Pipe (SDR-PR) Based on Outside Diameter.

- AWWA C906-15, AWWA Standard for Polyethylene (PE) Pressure Pipe and Fittings, 4 In. (100 mm) Through 63 In. (1,575 mm).

- Plastics Pipe Institute (PPI) Handbook of Polyethylene Pipe, 3rd Edition, 2017.

-

Flexible 32mm HDPE Pipes in Coil - Durable & Easy Install

NewsAug.18,2025

-

HDPE Sprinkler Pipe Manufacturers - Quality & Durable Solutions

NewsAug.17,2025

-

Durable DN100 PVC Well Casing Pipes for Reliable Water Supply

NewsAug.16,2025

-

HORON 25mm PPR Plumbing Pipes: Durable, Leak-Proof Water Systems

NewsAug.15,2025

-

Durable UPVC Column Pipes for Submersible Pumps | Efficient Water Flow

NewsAug.14,2025