Aug . 25, 2025 03:20 Back to list

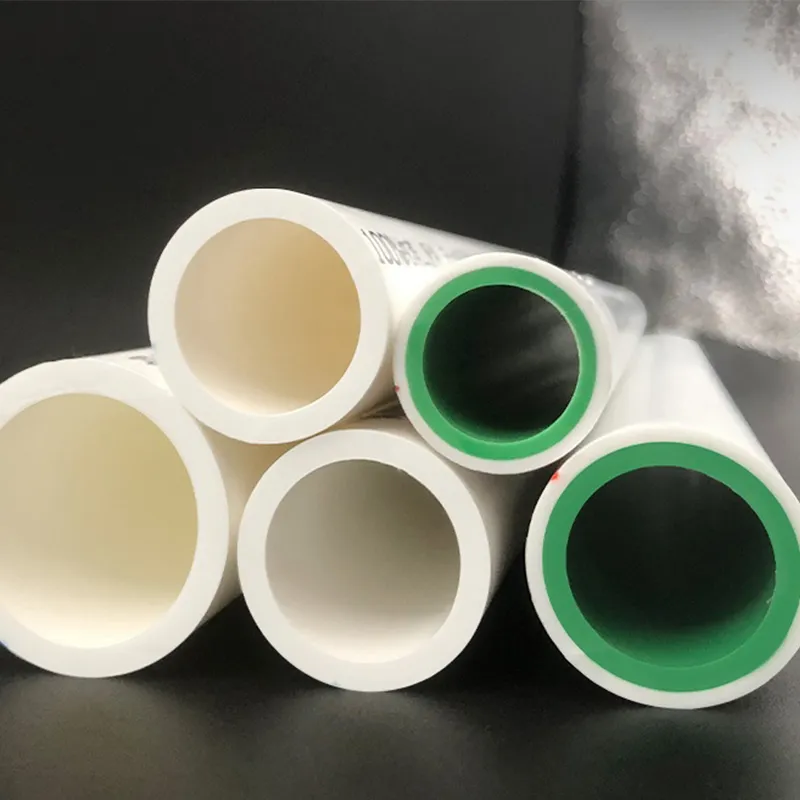

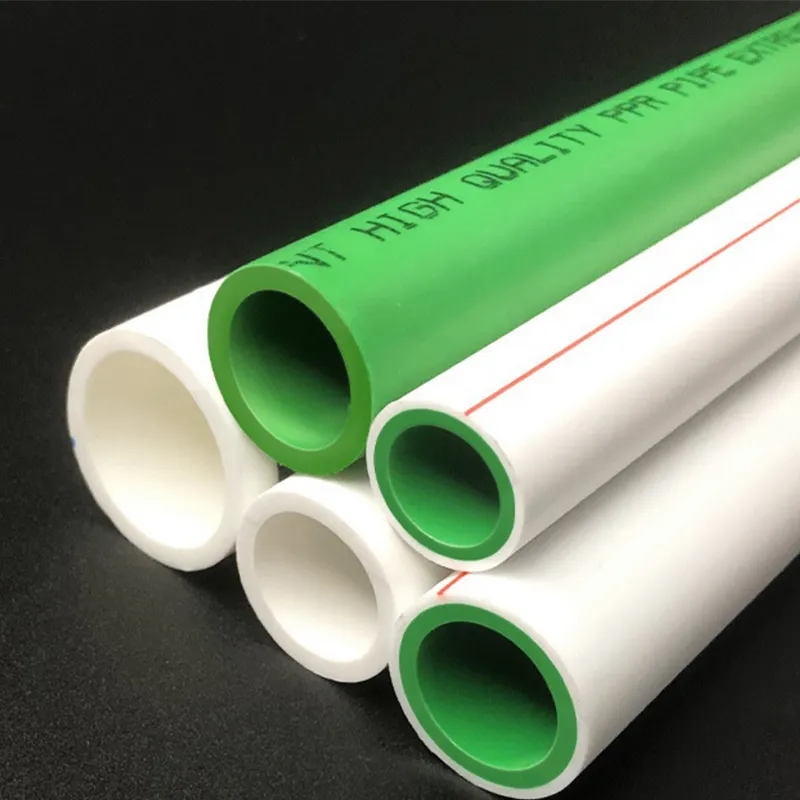

HORON 25mm PPR Plumbing Pipes: Durable, Leak-Proof Water Solutions

Industry Trends in Advanced Plumbing Solutions

The global infrastructure landscape is undergoing a significant transformation, driven by an increasing demand for sustainable, efficient, and durable plumbing systems. Traditional metallic piping, while historically prevalent, faces challenges such as corrosion, scaling, and high installation costs. This has propelled the adoption of advanced polymer-based solutions, with Polypropylene Random Copolymer (PPR) emerging as a frontrunner due to its exceptional material properties and economic viability.

Current industry trends emphasize longevity, hygiene, energy efficiency, and ease of installation. Engineers and project developers are increasingly specifying materials that can withstand aggressive operating conditions, offer superior thermal insulation, and contribute to healthier living and working environments. Furthermore, the integration of smart building technologies and the push for reduced carbon footprints necessitate piping systems that are not only robust but also environmentally benign throughout their lifecycle. In this context, the development and application of specialized PPR pipe systems, such as the HORON 25mm PPR Plumbing Pipes, represent a pivotal shift towards modern, high-performance fluid transport solutions designed to meet stringent B2B requirements.

The Manufacturing Excellence of HORON 25mm PPR Plumbing Pipes: A Detailed Process Flow

The production of HORON 25mm PPR Plumbing Pipes is a meticulously controlled process, ensuring the highest standards of quality, performance, and reliability. This commitment to precision begins with raw material selection and extends through every stage of manufacturing, adhering to global benchmarks like ISO 15874 and DIN 8077/8078.

1. Raw Material Sourcing and Quality Control

Our process begins with selecting only premium-grade Polypropylene Random Copolymer (PPR-Type 3), specifically tailored for pressure piping applications. This material is renowned for its excellent thermal stability, chemical inertness, and superior resistance to creep under sustained pressure at elevated temperatures. Each batch undergoes rigorous testing for Melt Flow Rate (MFR), density, tensile strength, and impact resistance to guarantee consistency and adherence to our exacting specifications.

2. Granulation and Homogenization

The selected PPR granules are meticulously dried to eliminate any moisture content, which could otherwise compromise the pipe's integrity during extrusion. They are then fed into a high-precision dosing system that ensures uniform blending, preventing material segregation and ensuring a homogenous melt composition, which is critical for consistent pipe wall thickness and structural integrity.

3. Precision Extrusion

The homogenized PPR material is fed into advanced single-screw extruders. Here, under precisely controlled temperature zones (typically ranging from 180°C to 230°C) and pressure, the polymer melts and is pushed through a sophisticated die head. This critical stage involves careful control of the melt temperature, pressure, and die gap to achieve uniform wall thickness, a perfectly smooth internal surface (reducing flow friction and energy consumption), and the exact 25mm outer diameter for the HORON 25mm PPR Plumbing Pipes. Our extrusion lines are equipped with gravimetric dosing systems to maintain constant output and prevent dimensional variations.

4. Controlled Cooling

Immediately after extrusion, the hot pipe enters a multi-stage vacuum calibration and cooling bath. This controlled cooling process, typically using chilled water, is vital. The vacuum ensures the pipe maintains its precise circular geometry and dimensional stability. Gradual cooling minimizes internal stresses, preventing material crystallization and ensuring the pipe retains its flexibility and long-term hydrostatic pressure resistance. Inadequate cooling control can lead to brittleness or reduced pressure capabilities.

5. Haul-off and Precision Cutting

A caterpillar haul-off unit gently pulls the cooled pipe at a consistent speed, preventing deformation and maintaining dimensional accuracy. The continuous pipe is then cut to precise, predefined lengths (e.g., 4m or 6m for standard installations) by an automatic, high-precision cutting machine. Each cut is clean and burr-free, preparing the pipes for immediate use or subsequent fitting processes.

6. Quality Assurance and Testing Standards

Every batch of HORON 25mm PPR Plumbing Pipes undergoes rigorous testing to ensure compliance with international standards such as ISO 15874 (Plastics piping systems for hot and cold water installations – Polypropylene) and DIN 8077/8078. Key tests include:

- Hydrostatic Pressure Testing: Pipes are subjected to sustained internal pressures at various temperatures (e.g., 20°C, 70°C, 95°C) for extended durations (up to 1000 hours) to verify long-term resistance to internal pressure, a critical parameter for service life.

- Impact Resistance: Testing for resilience against mechanical stress and accidental damage during installation or operation.

- Dimensional Verification: Precise measurement of outer diameter, wall thickness, and ovality using laser-based systems.

- Melt Flow Rate (MFR): Confirms the consistency of the raw material's processability.

- Thermal Cycling: Repeated exposure to hot and cold water to simulate real-world conditions and verify joint integrity.

This comprehensive testing regimen ensures a service life exceeding 50 years under specified operating conditions, making HORON 25mm PPR Plumbing Pipes an ideal choice for critical applications.

Target Industries and Key Advantages:

The robust design and verified performance of HORON 25mm PPR Plumbing Pipes make them indispensable across a broad spectrum of industries:

- Water Supply & Drainage: Potable hot and cold water systems in residential, commercial, and industrial buildings.

- HVAC Systems: Chilled water lines, radiant heating/cooling.

- Petrochemical & Chemical Processing: Transport of various non-aggressive chemicals due to superior corrosion resistance.

- Metallurgy: Industrial water lines, demineralized water distribution, and process fluid transfer.

- Agriculture: Irrigation systems, water distribution in greenhouses.

Advantages in typical application scenarios include significant energy saving due to reduced friction losses (Hazen-Williams C factor of 150 for smooth PPR vs. 100-120 for aged metal pipes) and unparalleled corrosion resistance, eliminating concerns about rust, scaling, and chemical degradation prevalent with metallic alternatives.

Technical Specifications and Performance Parameters

Understanding the precise technical parameters of HORON 25mm PPR Plumbing Pipes is crucial for engineers and project managers in designing robust and reliable fluid transport systems. Our pipes are manufactured to meet stringent specifications, ensuring optimal performance across a range of demanding applications. Below is a detailed overview of key parameters:

Product Specification Table: HORON 25mm PPR Plumbing Pipes

| Parameter | Specification |

|---|---|

| Nominal Diameter (DN) | 25 mm |

| Outer Diameter (OD) | 25.0 ± 0.3 mm |

| Wall Thickness (PN20) | 4.2 mm |

| Wall Thickness (PN25) | 4.9 mm |

| Material | PPR-Type 3 Random Copolymer Polypropylene |

| Operating Pressure (at 20°C) | PN20 (20 Bar) / PN25 (25 Bar) |

| Operating Pressure (at 70°C, 50-year life) | PN10 (10 Bar) for PN20 / PN12.5 (12.5 Bar) for PN25 |

| Operating Temperature Range | -5°C to +95°C (with appropriate pressure derating) |

| Thermal Conductivity | 0.24 W/m°C (significantly lower than metal) |

| Linear Expansion Coefficient | 1.5 x 10^-4 m/(m°C) |

| Surface Roughness (absolute) | 0.007 mm (extremely smooth) |

| Standards Compliance | ISO 15874, DIN 8077/8078 |

| Density | 0.9 g/cm³ |

These specifications highlight the robust engineering behind HORON 25mm PPR Plumbing Pipes, ensuring their suitability for demanding industrial and commercial applications requiring reliable and high-performance fluid transport.

Key Technical Advantages of HORON 25mm PPR Plumbing Pipes

The advanced material science and manufacturing precision inherent in HORON 25mm PPR Plumbing Pipes translate into a host of compelling technical advantages for B2B applications:

- Exceptional Corrosion and Chemical Resistance: Unlike metallic pipes susceptible to rust and galvanic corrosion, PPR is inert to a wide range of chemicals, acids, and bases. This makes HORON 25mm PPR Plumbing Pipes ideal for transporting various industrial fluids, demineralized water, and ensures no degradation of water quality in potable water systems. No scale build-up means consistent flow over decades.

- Superior Thermal Performance and Energy Efficiency: With a thermal conductivity of only 0.24 W/m°C, PPR significantly reduces heat loss in hot water lines and heat gain in chilled water systems. This inherent insulation property minimizes the need for extensive external insulation, leading to substantial energy savings in heating and cooling systems, and lowering operational costs over the pipe's long service life.

- Extended Longevity and Durability: Engineered for a service life exceeding 50 years under continuous operating conditions of up to 70°C and 10 bar pressure, these pipes offer an unparalleled return on investment. The material's molecular structure provides excellent resistance to creep, ensuring dimensional stability and hydrostatic strength over decades, far outlasting many traditional piping materials.

- Hygienic and Non-Toxic: Manufactured from food-grade PPR, these pipes do not impart taste, odor, or color to water and are free from heavy metals. This makes them perfectly suited for potable water distribution systems, ensuring the highest standards of water purity and public health compliance.

- Ease and Speed of Installation: PPR pipes are lightweight (approximately 1/9th the weight of steel pipes), simplifying handling and reducing labor costs. The heat fusion welding technique creates homogenous, molecularly bonded joints that are leak-proof and as strong as the pipe itself, eliminating the need for sealants, glues, or complex threading, thus drastically speeding up installation times on-site.

- Acoustic Damping Properties: The inherent elasticity of PPR helps to absorb noise generated by fluid flow and water hammer, contributing to quieter operation, particularly beneficial in commercial and residential settings.

- Flexibility and Impact Resistance: PPR maintains excellent ductility even at low temperatures (down to -5°C), reducing the risk of brittle fracture common with other plastics or metals during cold weather installation or accidental impact.

Diverse Application Scenarios for HORON 25mm PPR Plumbing Pipes

The versatility and robust performance characteristics of HORON 25mm PPR Plumbing Pipes make them ideally suited for a wide array of demanding B2B applications across various sectors:

- Hot and Cold Potable Water Systems: From high-rise commercial buildings and hotels to industrial complexes and residential developments, PPR pipes provide a hygienic, corrosion-free, and long-lasting solution for distributing drinking water. Their ability to handle temperatures up to 95°C ensures reliability for both domestic hot water supply and industrial process water.

- HVAC and Chilled Water Piping: Due to their low thermal conductivity, HORON 25mm PPR Plumbing Pipes are highly efficient for chilled water distribution in air conditioning systems, minimizing condensation and energy loss. They are also excellent for radiant floor heating and wall heating/cooling systems, providing uniform heat distribution and energy efficiency.

- Industrial Fluid Distribution: In sectors such as petrochemicals, metallurgy, and food processing, these pipes are employed for the safe and efficient transport of various non-abrasive industrial fluids, including demineralized water, process cooling water, and certain chemical solutions where their chemical inertness is critical.

- Agricultural and Greenhouse Irrigation Systems: The durability, resistance to chemicals (fertilizers, pesticides), and UV stability of PPR make it an excellent choice for irrigation lines, ensuring reliable water delivery to crops and plants over long periods.

- Solar Water Heater Connections: PPR's high-temperature resistance is perfectly matched for connecting solar thermal collectors to storage tanks, enduring the high temperatures generated by solar energy capture.

- Compressed Air Systems: For low-pressure compressed air distribution, HORON 25mm PPR Plumbing Pipes offer a lightweight, corrosion-resistant alternative to traditional metal pipes, reducing maintenance and installation complexities.

These diverse applications underscore the adaptability and superior performance of HORON's PPR solutions in challenging operational environments.

Vendor Comparison and HORON's Differentiators

In a competitive market for PPR piping solutions, discerning B2B clients evaluate vendors based on a confluence of factors including product quality, technical support, certifications, and overall value. While many manufacturers offer PPR pipes, HORON distinguishes itself through a commitment to unparalleled material science, advanced manufacturing technology, and comprehensive customer-centric solutions.

Key Differentiators for HORON 25mm PPR Plumbing Pipes:

- Uncompromised Material Purity: We exclusively utilize virgin, high-grade PPR-Type 3 random copolymer, sourced from leading global suppliers, ensuring superior mechanical properties and consistent long-term performance, unlike some competitors who may use recycled or lower-grade compounds.

- Precision Engineering and Manufacturing: Our production lines incorporate state-of-the-art extrusion technology with continuous online quality monitoring, including ultrasonic wall thickness measurement and laser diameter scanning. This results in pipes with exceptionally uniform wall thickness and concentricity, critical for pressure resistance and leak prevention.

- Rigorous Quality Assurance & Certifications: Beyond standard ISO requirements, every batch of HORON 25mm PPR Plumbing Pipes undergoes extensive hydrostatic testing at elevated temperatures and pressures, exceeding typical industry benchmarks. Our commitment is validated by multiple international certifications (e.g., ISO 9001, ISO 14001, CE, potentially WRAS or other regional specific approvals), providing independent assurance of quality and compliance.

- Comprehensive Technical Support: HORON offers deep technical expertise, including pre-sales consultation, project-specific design assistance, installation guidance, and post-sales support. This holistic approach ensures optimal system design and successful implementation for complex projects.

- Customization and Solution-Oriented Approach: We understand that every project has unique requirements. HORON excels in providing customized solutions, from specific lengths and colors to specialized fittings and integrated system components, tailored to client needs.

PPR Pipe Features Comparison

| Feature | Standard PPR Pipe (Typical) | HORON 25mm PPR Plumbing Pipes (Differentiated) |

|---|---|---|

| Material Quality | PPR-C (Type 3), sometimes with recycled content. | Virgin PPR-Type 3 premium-grade, consistent molecular structure. |

| Manufacturing Precision | Standard extrusion, occasional wall thickness variations. | Advanced gravimetric extrusion, precise diameter and uniform wall thickness (e.g., ±0.3mm tolerance). |

| Testing Standards | Compliance to minimum ISO/DIN requirements. | Exceeds ISO 15874, DIN 8077/8078 with enhanced hydrostatic and long-term creep tests. |

| Service Life | Typically 25-50 years. | Guaranteed 50+ years under specified conditions. |

| Chemical Resistance | Good for common applications. | Excellent broad-spectrum resistance to acids, alkalis, and salts (chemical inertness). |

| Customization Options | Limited standard offerings. | Extensive project-specific customization and engineering support. |

| After-Sales Support | Basic. | Comprehensive technical assistance, warranty, and dedicated account management. |

This comparison underscores HORON’s commitment to providing not just a product, but a superior, long-term solution that significantly reduces operational risks and costs for our B2B partners.

Customized Solutions for Complex Projects

Recognizing that off-the-shelf solutions often fall short for large-scale or specialized B2B projects, HORON offers comprehensive customized solutions leveraging our expertise in PPR piping. Our engineering team collaborates closely with clients from conceptualization to implementation, ensuring that the HORON 25mm PPR Plumbing Pipes system is precisely aligned with project demands and environmental specifications.

This includes developing custom pipe lengths to minimize waste and optimize installation, designing specialized fittings for unique connection requirements, or formulating pipes with specific pressure ratings and thermal properties for extreme operating conditions. Our capabilities extend to material selection consultation, flow dynamics analysis, and providing detailed CAD drawings for complex pipe layouts. By offering tailored solutions, HORON ensures that every project benefits from maximum efficiency, reduced installation time, and optimal long-term performance, reinforcing our commitment as a strategic partner.

Real-World Application Case Studies & Customer Experience

The efficacy and reliability of HORON 25mm PPR Plumbing Pipes are best demonstrated through their successful deployment in challenging real-world scenarios. Our extensive experience in the B2B sector has generated a track record of positive outcomes and strong client satisfaction.

Case Study 1: Large-Scale Commercial Building Potable Water System

Client Profile: A major property developer constructing a new 20-story commercial office tower in a metropolitan area, requiring a robust, hygienic, and long-lasting potable water distribution system.

Challenge: The client sought a piping solution that could guarantee water purity, resist corrosion over its expected 50+ year lifespan, and offer cost-effective installation compared to traditional copper or galvanized steel, while adhering to strict local health regulations for drinking water.

Solution: HORON supplied a comprehensive system utilizing HORON 25mm PPR Plumbing Pipes and a range of larger diameter PPR main lines and fittings. Our technical team provided design assistance to optimize pipe routing and thermal expansion compensation. The lightweight nature and fusion welding capabilities of PPR significantly streamlined the installation process.

Outcome: The project experienced a 25% reduction in installation time compared to projected metallic pipe installation. Post-installation water quality tests consistently showed zero contamination. The client reported excellent system performance, with no leaks or maintenance issues after three years of operation. The projected operational cost savings due to zero corrosion and minimal heat loss were significant. Customer feedback highlighted the ease of working with HORON's technical support and the superior quality of the pipes.

Case Study 2: Industrial Process Water Line in a Chemical Manufacturing Facility

Client Profile: A chemical plant specializing in mild acid and alkali production, needing to replace aging stainless steel lines for process cooling water and dilute chemical transport. The environment presented challenges of moderate temperatures (up to 60°C) and corrosive fluid exposure.

Challenge: The existing stainless steel pipes, despite their initial cost, were showing signs of localized corrosion and required frequent maintenance, leading to costly downtime. The client needed a material with superior chemical resistance and a longer maintenance-free lifespan.

Solution: Following a detailed chemical compatibility analysis conducted by HORON's material science specialists, HORON 25mm PPR Plumbing Pipes (and larger dimensions for main lines) were specified. The project involved replacing approximately 500 meters of piping and integrating it with existing infrastructure. HORON provided specialized fittings and training for the client's installation team on proper fusion welding techniques for chemical service.

Outcome: The new PPR system has been operational for five years without any reported leaks, corrosion, or material degradation. The chemical inertness of PPR has drastically reduced maintenance requirements, leading to an estimated 40% reduction in annual pipe-related maintenance costs. The smooth internal surface of the pipes also contributed to a marginal improvement in flow rates and reduced pumping energy. The client praised HORON for its expert material selection guidance and robust product performance in a demanding chemical environment.

These examples underscore HORON's capability to deliver high-performance, cost-effective, and reliable solutions across a diverse range of B2B applications, validated by real-world performance and positive customer experiences.

Authoritativeness & Trustworthiness: Certifications, Warranty, and Support

HORON's standing as a trusted partner in the B2B plumbing sector is built on a foundation of verifiable credentials, stringent quality control, and robust customer support. We understand that for engineers and procurement managers, assurance of product quality and reliability is paramount.

Certifications and Compliance:

Our manufacturing processes and products, including HORON 25mm PPR Plumbing Pipes, adhere to the highest international standards. We are proudly certified with:

- ISO 9001:2015 (Quality Management System): Ensures consistent product quality and customer satisfaction through a robust management system.

- ISO 14001:2015 (Environmental Management System): Demonstrates our commitment to environmental responsibility throughout our operations.

- ISO 45001:2018 (Occupational Health and Safety Management System): Guarantees a safe and healthy working environment for our employees.

- CE Mark: Confirms compliance with European health, safety, and environmental protection standards for products sold within the European Economic Area.

- DIN 8077/8078 & ISO 15874: Strict adherence to German and International standards for polypropylene pipes for hot and cold water installations.

- WRAS Approval (Water Regulations Advisory Scheme): (If applicable, specify if for UK market) Certifies fitness for contact with potable water in the UK.

These certifications provide independent verification of our unwavering commitment to quality, safety, and environmental stewardship.

Warranty Commitments:

HORON stands behind the quality and durability of its products. We offer a comprehensive 10-year warranty against manufacturing defects for all HORON 25mm PPR Plumbing Pipes, provided they are installed and operated according to our guidelines and industry best practices. This warranty underscores our confidence in the longevity and performance of our solutions, offering peace of mind to our clients.

Lead Time and Fulfillment:

With optimized production schedules and a robust global logistics network, HORON ensures efficient order processing and timely delivery. Standard lead times for HORON 25mm PPR Plumbing Pipes typically range from 2-4 weeks, depending on order volume and customization requirements. For urgent projects or large-scale procurements, we offer expedited options and work closely with clients to meet their critical timelines.

Customer Support and After-Sales Service:

Our commitment to client success extends beyond product delivery. HORON provides dedicated technical support, including:

- Expert Technical Assistance: Our engineering team is available for consultation on design, installation best practices, and troubleshooting.

- Installation Guidance: Providing detailed manuals and, where necessary, on-site or virtual training for proper fusion welding and system assembly.

- After-Sales Support: Prompt response to any queries or concerns post-installation, ensuring optimal system operation throughout its lifespan.

- Dedicated Account Management: Each client benefits from a dedicated account manager to streamline communication and support.

Frequently Asked Questions (FAQ)

-

Q1: What distinguishes PPR from other plastic piping materials like PVC or PEX?

A: PPR (Polypropylene Random Copolymer) offers superior resistance to high temperatures and pressures compared to PVC, making it suitable for hot water applications. Unlike PEX, PPR uses heat fusion welding for permanent, leak-proof joints, eliminating the need for mechanical connections and reducing failure points. PPR also boasts excellent chemical resistance and a very smooth inner surface, which reduces friction losses and inhibits scale formation more effectively.

-

Q2: What is the typical service life of HORON 25mm PPR Plumbing Pipes?

A: Under normal operating conditions (up to 70°C and specified pressures), HORON 25mm PPR Plumbing Pipes are engineered and tested to provide a service life exceeding 50 years. This longevity is a result of our high-quality raw materials and precision manufacturing processes that ensure resistance to thermal aging and hydrostatic stress.

-

Q3: Are HORON PPR pipes suitable for industrial chemical applications?

A: Yes, HORON 25mm PPR Plumbing Pipes exhibit excellent chemical resistance to a wide range of inorganic acids, alkalis, salts, and organic solvents. For specific chemical applications, we recommend consulting our technical team with detailed information on the chemical composition, concentration, and operating temperature to ensure optimal material compatibility and performance.

-

Q4: How does HORON ensure the quality of its PPR pipes?

A: Our quality assurance process is multi-layered. It includes rigorous raw material inspection, continuous in-line monitoring during extrusion (e.g., ultrasonic wall thickness, laser diameter control), and post-production testing such as hydrostatic pressure tests, melt flow rate analysis, and impact resistance tests. We adhere strictly to international standards like ISO 15874 and DIN 8077/8078, backed by ISO 9001 certification for our quality management system.

-

Q5: Can HORON provide customized PPR solutions for unique project requirements?

A: Absolutely. HORON specializes in providing tailored solutions. Our engineering team works collaboratively with clients to develop custom pipe lengths, specialized fittings, unique pressure ratings, and provide comprehensive technical assistance for project-specific designs. This ensures that the HORON 25mm PPR Plumbing Pipes system is optimized for your precise application needs.

Conclusion

The HORON 25mm PPR Plumbing Pipes represent a paradigm of advanced engineering and material science, offering unparalleled reliability, efficiency, and longevity for diverse B2B fluid transport applications. Through meticulous manufacturing, rigorous quality assurance, and comprehensive client support, HORON delivers not just a product, but a sustainable and cost-effective solution tailored to the demanding requirements of modern industrial and commercial infrastructure.

References

- International Organization for Standardization. ISO 15874-1:2013 Plastics piping systems for hot and cold water installations – Polypropylene (PP) – Part 1: General.

- Deutsches Institut für Normung e.V. DIN 8077: Polypropylene (PP) pipes - PP-H 100, PP-B 80, PP-R 80 and PP-R 100 pipes - General quality requirements, testing.

- Deutsches Institut für Normung e.V. DIN 8078: Polypropylene (PP) pipes - PP-H 100, PP-B 80, PP-R 80 and PP-R 100 pipes - Dimensions.

- Polypropylene Piping Systems: A Review of Properties, Processing, and Applications. Journal of Polymer Science.

- The Water Research Centre (WRc) & Water Regulations Advisory Scheme (WRAS) materials and product approval standards.

-

Hot/Cold DN25 PPR Water Pipes for Kitchen | Durable & Food-Safe

NewsAug.24,2025

-

DN100 PVC Pipes for Well Casings - Durable & Corrosion-Resistant

NewsAug.22,2025

-

HORON 25mm PPR Plumbing Pipes: Durable, Reliable & Leak-Proof

NewsAug.21,2025

-

32mm HDPE Pipes in Coil: Flexible & Durable Water Supply

NewsAug.19,2025

-

Flexible 32mm HDPE Pipes in Coil - Durable & Easy Install

NewsAug.18,2025