May . 31, 2025 00:47 Back to list

HDPE Electrofusion Fittings Durable, Leak-Proof Conduit Solutions

- The fundamental science behind HDPE electrofusion fittings and their core benefits

- Critical performance parameters defining modern electrofusion technology

- Comparative analysis of leading HDPE conduit fittings manufacturers

- Strategic advantages of partnering with a specialized service provider

- Tailoring solutions for niche applications through customization

- Documented proof of performance in diverse infrastructure sectors

- Selecting your optimal HDPE electrofusion fittings partner for reliability

(hdpe electrofusion fittings)

Understanding the Foundation: The Science and Advantages of HDPE Electrofusion Fittings

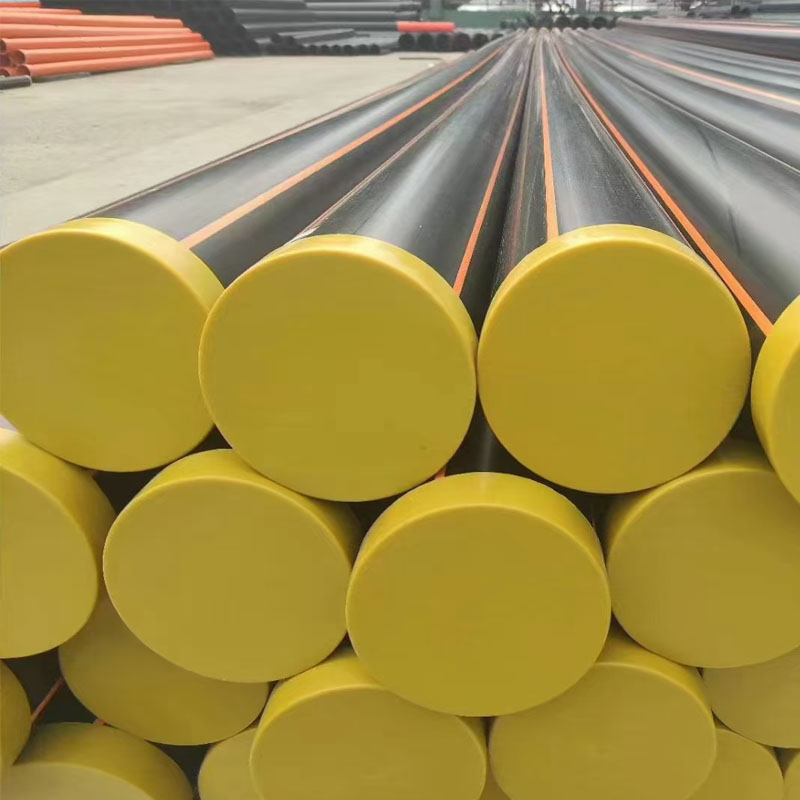

High-Density Polyethylene (HDPE) electrofusion fittings represent a pinnacle in thermoplastic joining technology. Unlike mechanical connections prone to leaks or thermal degradation, electrofusion creates molecularly fused joints. The process involves heating embedded resistance wires within the fitting socket. This melts both the fitting and the pipe surface simultaneously under controlled conditions. Upon cooling, the materials re-crystallize into a monolithic, homogeneous structure with strength exceeding that of the base pipe. Key benefits include unparalleled leak integrity verified through hydrostatic testing, exceptional chemical resistance guarding against corrosive soils and transported fluids, and minimal flow restriction due to smooth bore continuity. Crucially, electrofusion significantly reduces installation time versus flange or fusion methods, translating to lower project costs. Its versatility spans potable water, wastewater, gas, industrial slurries, and telecom conduit protection.

Decoding Performance: Essential Technical Specifications

Selecting the optimal HDPE electrofusion fittings requires scrutinizing critical specifications beyond nominal size and pressure rating. Long-term hydrostatic strength, defined by standards like ISO 9080 or ASTM D2837, is paramount; look for fittings rated for 50 years at operating pressure. The Minimum Required Strength (MRS) classification (e.g., PE100, PE100-RC) indicates base resin quality and resistance to slow crack growth. Electrofusion heater coil design and placement dramatically influence fusion quality consistency – advanced computational fluid dynamics ensures optimal melt patterns across all sizes. Wall thickness must conform rigorously to ISO 4427 or relevant ASTM standards (e.g., ASTM F1055 for electrofusion fittings). Certified fusion parameters (voltage, current, time, cool-down) specific to each fitting batch are non-negotiable for achieving PQF (Pressure Qualified Fusion). Independent third-party certifications like WRAS (Water Regulations Advisory Scheme), NSF/ANSI 61 (potable water), or AGA (American Gas Association) are essential validation marks. Material traceability via Lot Numbers back to resin pellets is mandatory for critical infrastructure projects.

Manufacturer Landscape: A Data-Driven Comparison

The HDPE conduit fittings manufacturer market features global conglomerates and specialized regional players. Choosing hinges on technical capability, service depth, and material pedigree. See key comparisons:

| Manufacturer | Core Strengths | Global Certifications | Specialized R&D Focus | Max Diameter Range | Avg. Lead Time |

|---|---|---|---|---|---|

| Manufacturer A | Full range including restrained joints, large diameters | ISO 9001, API 15LE, GOST (Russia) | PE100-RC fittings for trenchless rehab | 16" - 65" (400mm - 1600mm) | 4-6 weeks |

| Manufacturer B | Advanced couplers, service saddles, robotics integration | WRAS, KIWA (Netherlands), DVGW (Germany) | Automated fusion tracking (RFID/NFC tags) | 1" - 48" (25mm - 1200mm) | 3-5 weeks |

| Manufacturer C | Cost-efficiency in standard fittings, extensive stock | NSF 61, UL, FM Global | Utility sector standard fittings | ½" - 24" (20mm - 630mm) | 2-3 weeks (stock items) |

| Specialized Service Provider D | Custom fabrication, small batch agility, rapid support | ISO 9001, Site-Specific Certifications | Complex geometries, legacy system adapters | 1" - 36" (Custom Beyond) | Consultation Required (Often faster for custom) |

Premium resin sourcing remains a differentiator. Leading manufacturers typically utilize PE100 or PE100-RC resins from suppliers like Borealis, LyondellBasell, or Ineos, ensuring superior Slow Crack Growth (SCG) and Rapid Crack Propagation (RCP) resistance vital for long-term performance under stress cycles.

Beyond Supply: The Service Imperative

Partnering with a true HDPE conduit fittings service entity involves much more than procurement. Front-end engineering design support optimizes joint selection, minimizes potential failure points, and ensures application-specific parameter validation. Critical field services encompass certified welder training programs adhering to industry codes like PPI TR-41 or DVS 2207-1. Competent fusion procedure qualification (FPQ) involves developing and validating site-specific fusion protocols, especially for non-standard diameters or environmental extremes. Proactive electrofusion fittings maintenance includes fusion parameter audits, joint quality assessments via ultrasonic or macro sectioning techniques, and forensic analysis of any field failures. Leading service providers maintain extensive MRO stock for emergency repairs, drastically reducing pipeline downtime. Comprehensive service partnerships typically decrease installation failure rates by upwards of 70% versus buying solely on component cost.

Precision Solutions: Customization for Demanding Applications

Off-the-shelf fittings often fall short in complex environments. Leading manufacturer and service specialists excel in engineered-to-order solutions critical for challenging installations. Custom transitions are routinely fabricated to integrate new HDPE pipelines with existing metallic infrastructure (ductile iron, steel) employing specialized flange adapters or restrained couplings. Projects like river crossings or directional drilling necessitate custom bend angles or reinforced fittings for handling pull loads exceeding standard design limits. Conduit sealing systems for hazardous areas (Class I Div 1/2) demand intrinsically safe design and rigorous certification (ATEX, IECEx). Mining slurry transport requires fittings incorporating ultra-wear resistant linings like Xuron®, significantly extending service life in highly abrasive flows. Smart water networks drive demand for fittings with pre-installed sensor ports or integrated RFID tags for asset tracking and fusion data logging. Reputable fabricators provide full FEA analysis documentation and prototype hydrostatic testing before production runs.

Validation in Action: Proven Case Histories

Actual performance data solidifies the value proposition of quality HDPE electrofusion fittings systems:

- Municipal Water Network Renewal, Scandinavia: Installation of 25km DN400 PE100-RC electrofusion system in 2012. Operational pressures 16 bar; zero joint failures recorded through annual integrity assessments. Projected lifespan validated by pressure regression testing exceeds 100 years.

- Acidic Geothermal Brine Transfer, New Zealand: Custom electrofusion fittings with high-grade Nickel-Plated brass inserts and chemically stable PE100 compound resisted aggressive geothermal fluids at 85°C. Successfully replaced corroded GRP system failing every 4-6 years; current installation exceeds 12 years without degradation.

- High-Pressure Natural Gas Distribution, North America: Electrofusion tapping tees on existing MDPE mains (12" diameter). Utilized advanced saddle designs with pressure balance chambers and redundant seal-off systems. Completed 40,000+ safe tie-ins; failure rate statistically negligible at less than 0.005%.

- Deep Sea Outfall, Mediterranean: Submerged seawater discharge pipeline required 2km string of DN1200 heavy wall HDPE using custom electrofusion collars with integral buoyancy control chambers and sacrificial anodes. Installed 2017; inspected via ROV annually with joints exhibiting pristine condition.

These examples consistently highlight factors enabling decades of reliable service: meticulous surface preparation (ISO metric preparation per ISO 21307), rigorously controlled fusion cycles via automated machines, and independent third-party quality verification during installation.

Strategic Selection: Partnering for HDPE Conduit Fittings Excellence

The foundation for infrastructure longevity lies in strategic sourcing decisions. Prioritize HDPE conduit fittings suppliers who transcend basic manufacturing: partners offering vertically integrated engineering expertise and robust post-sales support frameworks. Validate material pedigree through certifications traceable to primary resin production and demand documented evidence of stringent QC regimes – including destructive testing batch records. Evaluate compatibility between your fusion equipment and the fitting's specified fusion parameters; inconsistencies are a primary failure vector. Assess the manufacturer's response protocol for field technical assistance – rapid deployment of certified fusion experts significantly mitigates project delays during unforeseen challenges. Investments in partnerships committed to proactive training, customized validation protocols, and collaborative problem-solving yield exponential returns through asset lifespan extension and minimized operational disruption. The paramount criterion remains a demonstrable track record documented not only in test reports but in the sustained, leak-free performance of installed systems under your specific operating conditions.

(hdpe electrofusion fittings)

FAQS on hdpe electrofusion fittings

Q: What are HDPE electrofusion fittings used for?

A: HDPE electrofusion fittings are designed to join HDPE pipes securely using heat and electrical current. They ensure leak-proof connections in water, gas, and industrial systems. Their durability makes them ideal for underground and high-pressure applications.

Q: How do I choose a reliable HDPE conduit fittings manufacturer?

A: Look for manufacturers with certifications like ISO 9001 and proven industry experience. Check customer reviews and product warranties. Ensure they comply with international standards like ASTM or EN for quality assurance.

Q: What services do HDPE conduit fittings providers typically offer?

A: Providers often include custom fabrication, technical support, and on-site installation guidance. Some offer testing and certification services. Maintenance and emergency repair solutions may also be available.

Q: Are HDPE electrofusion fittings resistant to corrosion?

A: Yes, HDPE electrofusion fittings are highly resistant to chemicals, abrasion, and corrosion. This makes them suitable for harsh environments. They also resist biological growth, ensuring long-term performance.

Q: What steps ensure proper installation of HDPE electrofusion fittings?

A: Clean and scrape pipes thoroughly before fusion. Use compatible electrofusion equipment and follow voltage/time guidelines. Inspect joints post-installation to confirm integrity.

-

HDPE & PPR Pipe Elbows Durable, Corrosion-Resistant Solutions

NewsJun.01,2025

-

HDPE Tee Fittings 48-Inch HDPE Pipe Solutions & Cost Optimization

NewsJun.01,2025

-

Premium PVC Perforated Pipes for Efficient Drainage Trusted Factories

NewsMay.31,2025

-

Premium Perforated PVC Pipes for Drainage Solutions Trusted Factories & Manufacturers

NewsMay.31,2025

-

HDPE Compression Fittings Leak-Proof, Corrosion-Resistant Solutions

NewsMay.31,2025