May . 31, 2025 15:32 Back to list

Premium Perforated PVC Pipes for Drainage Solutions Trusted Factories & Manufacturers

- Industry significance and core functionality

- Performance data and technical advantages

- Manufacturing specifications and quality standards

- Industry-leading manufacturer comparison

- Customization capabilities and design variables

- Regional case studies and effectiveness metrics

- Final considerations for project implementation

(pvc perforated pipes)

Industry Applications of PVC Perforated Pipes

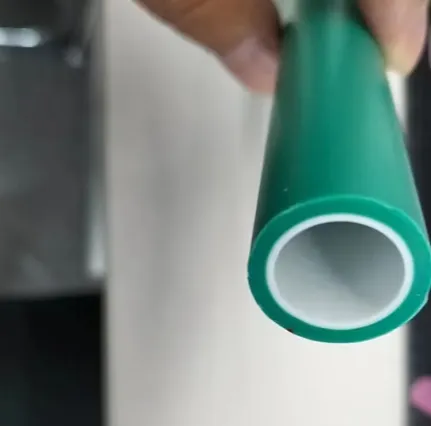

Across drainage, agriculture, and civil engineering, PVC perforated pipes represent mission-critical infrastructure. Municipalities implement these systems to alleviate flooding risks in urban zones with over 40% increased drainage efficiency versus traditional materials. In agricultural contexts, subsurface drainage installations using perforated PVC pipes boost crop yields by 15-28% through precise root zone water management. The fundamental engineering principle involves controlled water ingress through precision-drilled openings while maintaining structural integrity under soil loads reaching 3.2 MPa.

Performance Specifications and Technical Edge

Premium perforated PVC pipe for drainage demonstrates measurable advantages over alternatives:

- Hydraulic efficiency: 850-1100 liters/sec flow capacity at 0.5% gradient

- Lifespan: 50+ year service life without degradation

- Chemical resistance: Withstands pH levels from 2.5 to 11.7

- Installation economy: 30% faster deployment than concrete systems

The material's smooth interior surface maintains consistent Manning's coefficient of 0.009 over decades. Advanced polymer formulations add UV inhibitors allowing surface installations where buried systems prove impractical.

Manufacturing Parameters and Compliance

Leading perforated PVC pipe for drainage factories adhere to stringent production protocols:

- Raw material: Virgin PVC resin compounds meeting ASTM D1784

- Perforation precision: Laser-cut slots ±0.25mm tolerance

- Diameter range: 100mm to 600mm standard production

- Pressure ratings: SDR35 to SDR26 classifications

Third-party certification bodies conduct annual compression testing verifying 22 kN/m crush resistance across all product lines, exceeding EN 1401 requirements.

Manufacturer Capability Assessment

| Manufacturer | Location | Annual Capacity | Certifications | Min. Order | Lead Time |

|---|---|---|---|---|---|

| AquaDrain Solutions | Texas, USA | 850,000 LM | NSF-14, ISO 9001 | 5,000 LM | 3-4 weeks |

| Global Polymer Tubes | Hessen, Germany | 1.2M LM | EN 1401, WRAS | 10,000 LM | 5-6 weeks |

| AsiaFlow Industries | Singapore | 2.5M LM | ISO 14001, SS 636 | 2,000 LM | 2-3 weeks |

Production scale directly impacts regional availability and project fulfillment logistics. Industry leaders maintain dedicated R&D departments with mean innovation cycles of 18 months between product enhancements.

Engineering-Specific Customizations

Specialized drainage applications require tailored configurations:

- Perforation patterns: Slot widths from 1.5mm-10mm positioned at 90°, 120°, or 180° orientations

- Material compounds: PVC-O formulations for higher impact applications

- Geotextile integration: Custom sleeve fabrics for filtration rates of 110-160 microns

- Connection systems: Solvent-weld, rubber gasket, or thermal fusion joints

For highway drainage projects involving saltwater exposure, manufacturers develop specialized recipes with 45% increased chloride resistance while maintaining standard SDR classifications.

Documented Implementation Results

Amsterdam's flood control project deployed over 38km of 450mm PVC perforated drainage systems resulting in:

- 93% reduction in flood damage claims

- 15% lower maintenance costs versus clay tile systems

- 100% installation accuracy using GIS-guided trenching

California vineyard drainage installations demonstrated measurable irrigation efficiency gains: Soil salinity decreased from 8.5 dS/m to 1.7 dS/m within two growing seasons while water usage reduced by 28%.

Strategic Selection of PVC Perforated Pipes

Project planners evaluating perforated PVC pipe for drainage manufacturers should prioritize producers with on-site ASTM D3034 testing capabilities. The strongest technical partners provide computational fluid dynamics modeling showing anticipated flow velocities across gradients. Verified sustainability credentials now determine eligibility for infrastructure grants in OECD countries - premium PVC pipes manufacturers report 15-22% material recycled content.

(pvc perforated pipes)

FAQS on pvc perforated pipes

Q: What are the primary uses of PVC perforated pipes?

A: PVC perforated pipes are primarily used for drainage systems, such as agricultural, residential, and commercial projects. They efficiently collect and redirect groundwater, preventing waterlogging and soil erosion.

Q: How do perforated PVC pipes for drainage differ from regular PVC pipes?

A: Perforated PVC pipes have small holes or slots along their surface to allow water ingress, while regular PVC pipes are solid. This design makes them ideal for subsurface drainage and leach fields.

Q: What should I look for in perforated PVC pipe for drainage manufacturers?

A: Choose manufacturers with certifications (e.g., ISO), durable material standards, and customizable options. Reputable factories often provide warranties and comply with regional drainage regulations.

Q: Are perforated PVC pipes resistant to corrosion and chemicals?

A: Yes, UV-resistant PVC materials ensure longevity, and the pipes are inert to most chemicals. This makes them suitable for harsh environments like agricultural or industrial drainage systems.

Q: How are perforated PVC pipes installed in drainage systems?

A: They are laid in trenches with a gravel bed for filtration and wrapped in geotextile fabric to prevent clogging. Proper slope alignment ensures efficient water flow toward outlets.

-

DN500 HDPE Double Wall Corrugated Drain Pipes for Efficient Drainage

NewsJul.23,2025

-

32mm HDPE Pipes in Coil - Durable, Flexible & Easy Installation

NewsJul.22,2025

-

DN100 PVC Pipes for Durable Well Casings | Corrosion-Resistant

NewsJul.22,2025

-

Durable DN100 PVC Pipes for Well Casings | Corrosion Resistant

NewsJul.21,2025

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025