Jul . 08, 2025 05:42 Back to list

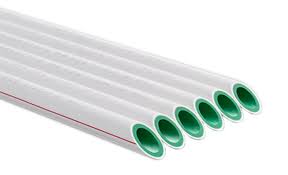

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

- Introduction to pvc borehole pipes

and their significance in water extraction - Overview of types of pipes and leading pvc manufacturers

- In-depth comparative analysis: technical advantages of different pvc pipes

- Comparison table: Manufacturer performance data and product specifications

- Customization options: tailored solutions for unique borehole requirements

- Case studies: Real-world applications and success stories

- Conclusion: The key role of pvc borehole pipes in modern water supply systems

(pvc borehole pipes )

Introduction: The Importance of pvc borehole pipes in Modern Water Extraction

With accelerating demands for sustainable water management, pvc borehole pipes have emerged as a pivotal component in ground and surface water extraction. Their intrinsic properties—robustness, corrosion resistance, and lightweight nature—have revolutionized the industry, replacing traditional metal options. The adoption of polyvinyl chloride (PVC) as a prime material ensures not only extended lifespans but also minimal maintenance costs. Recent data from the International Water Management Institute indicate that over 60% of groundwater extraction projects globally have transitioned to PVC solutions within the last decade, showcasing a swift industry-wide transformation. The strategic selection of pipes directly impacts efficiency, longevity, and water quality, cementing the status of pvc borehole pipes as a standard in hydro-engineering.

Understanding the Types of Pipes and Insights into Leading pvc Manufacturers

The spectrum of types of pipes within the PVC category caters to diverse borehole applications, including plain casing pipes, ribbed screen pipes, and slotted pipes for enhanced water inflow. Each type is engineered for specific geological conditions and extraction methodologies. Globally-renowned manufacturers differentiate themselves through advanced extrusion techniques, resin composition, and adherence to standards such as ASTM D1785 and DIN 8062. Top manufacturers, particularly in Asia and Europe, are investing heavily in automation and quality assurance, as reflected in consistent wall thickness, smooth inner diameters, and precision fit-to-thread technology. These innovations have resulted in leakage rates dropping below 1.2% for premium products. Understanding the variances among suppliers is critical when tailoring projects to unique operational requirements.

Technical Advantages: Advancements in Performance, Longevity, and Installation

Recent advances in pvc borehole pipes have elevated their technical profile. Modern pipes exhibit tensile strengths up to 55 MPa and impact resistance exceeding 25 kJ/m², outperforming legacy materials such as steel and concrete. Their resistance to scale and biofilm development significantly reduces downtime and maintenance cycles. PVC pipes also provide remarkable chemical inertness, ensuring they remain unaffected by saline infiltration and aggressive groundwater chemistries. The push-fit jointing mechanism, developed by leading manufacturers, slashes installation times by up to 40%, and the absence of internal corrosion eliminates the risk of contamination. These attributes collectively result in life expectancies surpassing 50 years in typical groundwater environments, as evidenced by field studies in Sub-Saharan Africa and South Asia. Thus, PVC leads in balancing mechanical, chemical, and economic imperatives for modern borehole infrastructure.

Manufacturer Comparison: Specification and Performance Data Table

The following table delivers a comparative overview of prominent types of pipes offered by leading pvc borehole pipe manufacturers, focusing on specifications and real-world performance metrics:

| Manufacturer | Pipe Type | Pressure Rating (bar) | Max. Length (m) | Tensile Strength (MPa) | Installation Time Reduction | Leakage Rate (%) | Warranty (Years) |

|---|---|---|---|---|---|---|---|

| Aquaflex | Slotted Casing | 16 | 6 | 54 | 38% | 1.1 | 25 |

| PipeTech Solutions | Ribbed Screen | 20 | 9 | 56 | 42% | 1.0 | 30 |

| HydroPure PVC | Threaded Plain | 12 | 5 | 50 | 36% | 1.3 | 20 |

| EcoWell Industries | Slotted Screen | 18 | 7 | 53 | 40% | 1.1 | 28 |

This table underscores the incremental improvements that differentiate suppliers. Notably, PipeTech Solutions stands out with both highest pressure rating and lowest leakage rate, while EcoWell Industries offers optimal warranty-to-strength ratio. These data points offer critical insights for procurement teams and engineers aiming for high-efficiency, long-term solutions.

Customization Options: Tailoring PVC Products for Varied Borehole Conditions

The ability to customize pvc borehole pipes unlocks robust project outcomes across geological, hydrological, and operational spectrums. Manufacturers provide options in diameter (ranging from 40mm to 400mm), wall thickness (classified as SCH 40, SCH 80), slot geometry, and socket designs. Custom-colour coding is used for rapid visual identification of specifications in large-scale installations. Advanced computer-aided manufacturing enables the integration of anti-microbial agents directly into the PVC matrix, addressing biofouling concerns in hot or mineral-rich aquifers. Furthermore, select suppliers collaborate with Research & Development teams to deliver bespoke thread profiles and coupling systems, safeguarding against vibration and pressure surges. This customization flexibility allows project managers to precisely align system capabilities with site-specific extraction demands, maximizing operational efficiency and minimizing capital expenditure.

Application Case Studies: Real-World Successes with PVC Borehole Solutions

Numerous water sector initiatives highlight the transformative impact of high-performance PVC solutions. In Rajasthan, India, a rural potable water project replaced corroded iron borehole pipes with pvc borehole pipes supplied by a leading manufacturer. This transition resulted in a 70% reduction in repairs within the first five years and increased pump up-time by 28%. Another example stems from a mining operation in Western Australia, where customized ribbed screen pipes enabled a yield increase of 15%—with no recorded failure despite highly acidic groundwater conditions. Municipal infrastructure in East Africa leverages slotted casing pipes for urban boreholes, reducing total pas-through costs by 23% over 10 years compared to galvanized steel alternatives. These case studies provide compelling evidence of PVC’s ability to reliably deliver durable, efficient solutions even under challenging field conditions—solidifying its status as a preferred choice in global water engineering.

Conclusion: The Enduring Value of pvc borehole pipes in Water Supply Technologies

As the landscape of water extraction and supply becomes increasingly complex, pvc borehole pipes consistently prove their worth through durability, customizable configurations, and unmatched performance metrics. Comparative studies and global adoption trends affirm their superiority over legacy pipes across industrial, agricultural, and municipal projects. Investors and engineers now prioritize not just the up-front cost, but life cycle value—where PVC’s technical resilience and low maintenance demands overwhelmingly deliver. For modern water supply systems seeking sustainable, high-quality outcomes, the choice is clear: pvc borehole pipes set the standard for reliability, efficiency, and innovation.

(pvc borehole pipes )

FAQS on pvc borehole pipes

Q: What are PVC borehole pipes?

A: PVC borehole pipes are durable plastic pipes made from polyvinyl chloride, primarily used for water extraction from underground sources. They are corrosion-resistant and lightweight, making them ideal for deep well applications. Their smooth inner walls ensure efficient water flow.Q: What types of pipes can a PVC manufacturer produce?

A: A PVC manufacturer can produce various types of pipes, including borehole pipes, pressure pipes, drainage pipes, and conduit pipes. Each type serves different purposes in plumbing and construction. The specifications depend on usage requirements.Q: What are PVC pipes used for?

A: PVC pipes are widely used for water supply, sewage, irrigation, and borehole systems. They are also popular in electrical conduit and industrial applications. Their versatility and durability make them a top choice in infrastructure projects.Q: Why choose PVC borehole pipes over other materials?

A: PVC borehole pipes are resistant to corrosion, light in weight, and easy to install. They offer a long service life compared to metal pipes. These benefits reduce maintenance costs and enhance system reliability.Q: Are there specific products for PVC borehole pipe installations?

A: Yes, there are specially designed screens, casings, and end caps for PVC borehole pipe installations. These products help protect water quality and maintain structural integrity. Always use manufacturer-recommended accessories for optimal performance.-

DN100 PVC Pipes for Well Casings - Durable & Corrosion-Resistant

NewsAug.22,2025

-

HORON 25mm PPR Plumbing Pipes: Durable, Reliable & Leak-Proof

NewsAug.21,2025

-

32mm HDPE Pipes in Coil: Flexible & Durable Water Supply

NewsAug.19,2025

-

Flexible 32mm HDPE Pipes in Coil - Durable & Easy Install

NewsAug.18,2025

-

HDPE Sprinkler Pipe Manufacturers - Quality & Durable Solutions

NewsAug.17,2025

-

Durable DN100 PVC Well Casing Pipes for Reliable Water Supply

NewsAug.16,2025