Mar . 02, 2024 11:44 Back to list

PPR Pipes Uses And Advantages

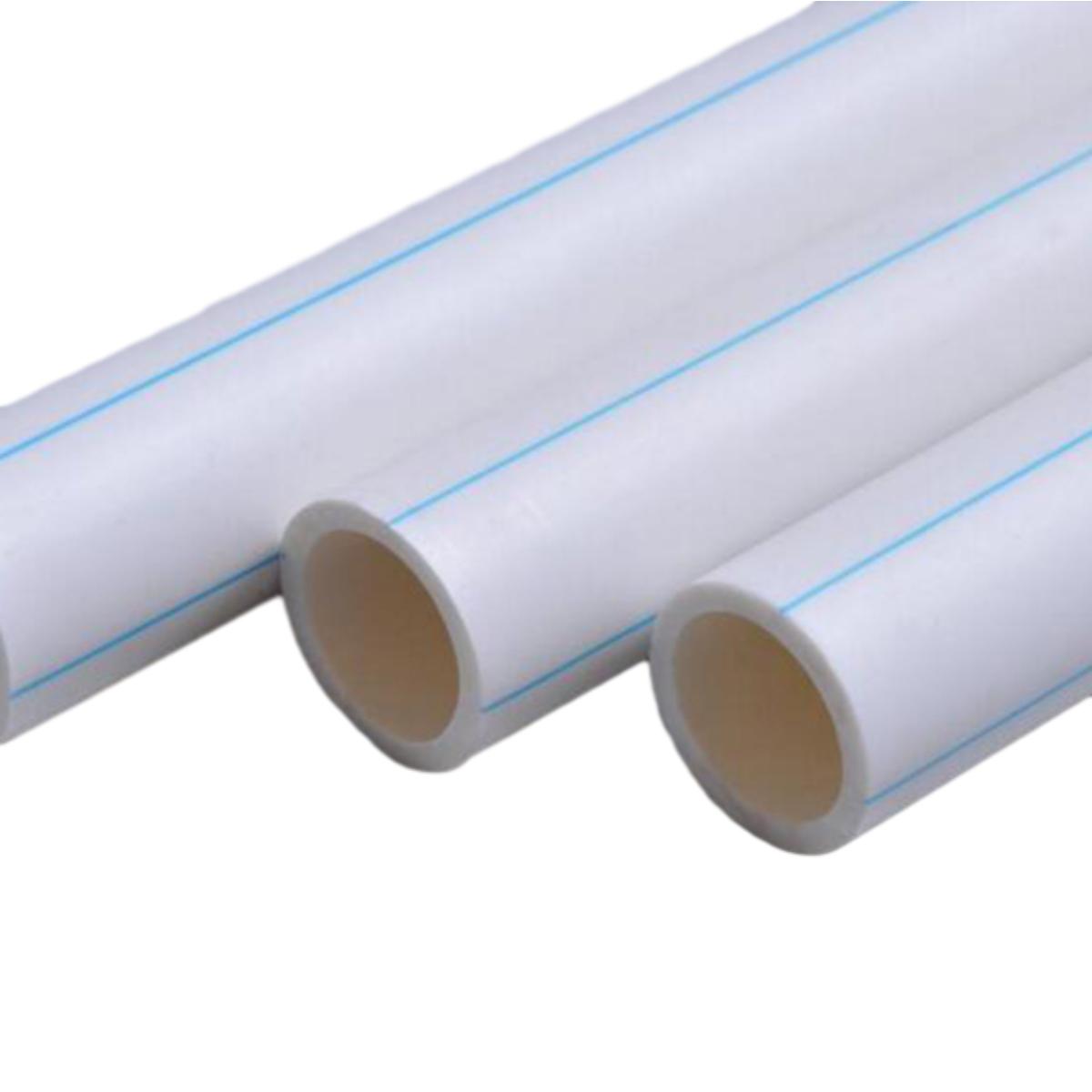

PPR pipes, also known as polypropylene random copolymer pipes, have been gaining popularity in various industries due to their durability, ecological benefits, and economic efficiency. These pipes are commonly used in home installations, water supply systems, hot water pipe systems, heating pipe systems, and air conditioning pipe systems. In this comprehensive guide, we will explore everything you need to know about PPR pipes, including their characteristics, main uses, advantages, and installation process.

What Are PPR Pipes?

PPR pipes are cylindrical and rigid pipes made from polypropylene random copolymer (PPR) plastic. They are produced through a continuous extrusion process and are usually available in white or green colors. These pipes come in various diameters, ranging from 20mm to 110mm, and feature a network of fittings, accessories, and parts designed for each specific diameter.

PPR pipes are known for their low thermal conductivity, which minimizes heat loss or gain during the transfer of cold and hot fluids. They also have increased longevity and can withstand both cold and hot water systems without breaking. Additionally, PPR pipes are ecologically and economically efficient, as they are easy to transport, cut, join, and do not require additional chemicals or materials.

Main Uses Of PPR Pipe Fittings

PPR pipe fittings have a wide range of applications due to their economic, ecological, and durability benefits. Let’s explore the main uses of PPR pipe fittings:

- Water Supply Systems: PPR pipe fittings are commonly used in water supply systems for both cold and hot water. Their ability to withstand high temperatures without breaking or cracking makes them an ideal choice for transporting water.

- Sewage Systems: PPR pipe fittings are suitable for discharging chemical fluids, including industrial waste, due to their resistance to strong chemicals and alkaline solutions.

- Heating Systems: PPR pipes are perfect for building heating systems, such as radiant and wall heating systems. They can withstand various surfaces and conditions, making them a reliable option for all heating needs.

- Air Conditioning Systems: PPR pipe fittings are also used in air conditioning pipe systems, ensuring the efficient transfer of fluids throughout the system.

- Irrigation Systems: PPR pipes can be used for irrigation purposes, providing a reliable and durable solution for transporting water to agricultural fields or gardens.

- Gas Transmission: PPR pipe fittings can be used for gas transmission in certain applications, as they have good resistance to chemicals and can ensure the safe transportation of gases.

- Fire Suppression Systems: PPR pipes meet UL standards for fire suppression systems, making them suitable for carrying gases or liquids from tanks to nozzles or sprinklers in buildings.

- Other Applications: PPR pipe fittings are also used in various industries that require non-metallic piping components, such as dairy farms, commercial kitchens, commercial complexes, and hobbyist projects.

Advantages Of PPR Pipes

PPR pipes offer several advantages compared to other piping materials. Let’s explore the top benefits of using PPR pipe fittings:

- Corrosion Resistance: PPR pipes have a low corrosion rate in water environments and are resistant to atmospheric oxygen and carbon dioxide. They have good anticorrosive performance, making them last longer than metal materials in similar environmental conditions.

- Lightweight: PPR pipes have a lower density than water, making them lighter than other piping options. This makes transportation and installation easier, reducing overall costs.

DN25 PPR water pipes for kitchen

- Flexibility: PPR pipes have good flexibility compared to metal pipes, allowing them to be installed around corners without sharp angles or bends. This flexibility simplifies the installation process.

- High Durability: PPR pipes are highly durable and can withstand various conditions, including high temperatures and pressure. They do not rust, corrode, or easily break, ensuring a long lifespan.

- Energy Efficiency: PPR pipes have low thermal conductivity, minimizing heat loss or gain during the transfer of fluids. This results in energy savings and reduced costs.

- Chemical Resistance: PPR pipes have excellent resistance to a wide range of chemicals, making them suitable for various applications, including sewage systems and industrial processes.

- Easy Installation: PPR pipes can be easily transported, cut, and joined without the need for additional chemicals or materials. This simplifies the installation process and saves time and effort.

- Safe for Potable Water: PPR pipes are non-toxic and do not carry any toxic materials. They are safe for transporting potable water and do not cause any pollution.

How To Join PPR Pipes

Joining PPR pipes is a straightforward process that requires careful attention to ensure a proper connection. Here is a step-by-step guide for joining PPR pipes:

- Prepare the Pipes: Cut the PPR pipes to the desired length using a pipe cutter or saw. Ensure that the ends are clean and free from debris.

- Prepare the Fittings: Clean the inside of the PPR fittings using a cleaning brush or sandpaper to remove any dirt or debris. Ensure that the fittings are dry before proceeding.

- Heat the Pipes and Fittings: Use a PPR welding machine to heat both the pipes and fittings. The machine should be set to the appropriate temperature for the specific PPR material being used.

- Insert the Pipes: Insert the heated pipes into the corresponding fittings while the material is still hot. Apply slight pressure to ensure a tight fit.

- Hold and Cool: Hold the pipes and fittings together for a few seconds to allow them to cool and solidify. This will ensure a strong and secure connection.

- Repeat the Process: Repeat the process for each joint, ensuring that all connections are properly heated and secured.

Remember to follow the manufacturer’s instructions and guidelines for the specific PPR pipes and fittings being used. It is essential to use the correct temperature and heating time to avoid damaging the pipes or fittings.

Horonpipe: The Leading PPR Pipe Manufacturer

When it comes to reliable and high-quality PPR pipes, Horonpipe is a leading manufacturer in the industry. With a wide range of products and specifications, Horonpipe offers PPR pipe fittings that meet international standards. Their PPR pipes are known for their durability, corrosion resistance, and ease of installation. Whether you need PPR pipes for water supply systems, heating systems, or any other application, Horonpipe has the perfect solution.

Conclusion

PPR pipes are an excellent choice for various applications due to their durability, ecological benefits, and economic efficiency. They are widely used in water supply systems, sewage systems, heating systems, and air conditioning systems, among others. With their low thermal conductivity, high durability, and resistance to corrosion and chemicals, PPR pipes offer numerous advantages over other piping materials. By following the proper installation techniques and using quality PPR pipes and fittings, you can ensure reliable and efficient plumbing systems in your projects. Choose Horonpipe as your trusted PPR pipe manufacturer and enjoy the benefits of high-quality piping solutions.

-

HORON 25mm PPR Plumbing Pipes: Durable, Leak-Proof Water Systems

NewsAug.15,2025

-

Durable UPVC Column Pipes for Submersible Pumps | Efficient Water Flow

NewsAug.14,2025

-

DN100 PVC Well Casing Pipes - Durable & Corrosion-Resistant

NewsAug.13,2025

-

Flexible 32mm HDPE Pipes in Coil | Durable Water & Gas Lines

NewsAug.12,2025

-

DN50 HDPE Pipes in Coils: Flexible, Durable & Easy Install

NewsAug.11,2025

-

32mm HDPE Pipes in Coil: Durable, Flexible, Easy Install

NewsAug.10,2025