Sep . 02, 2024 23:25 Back to list

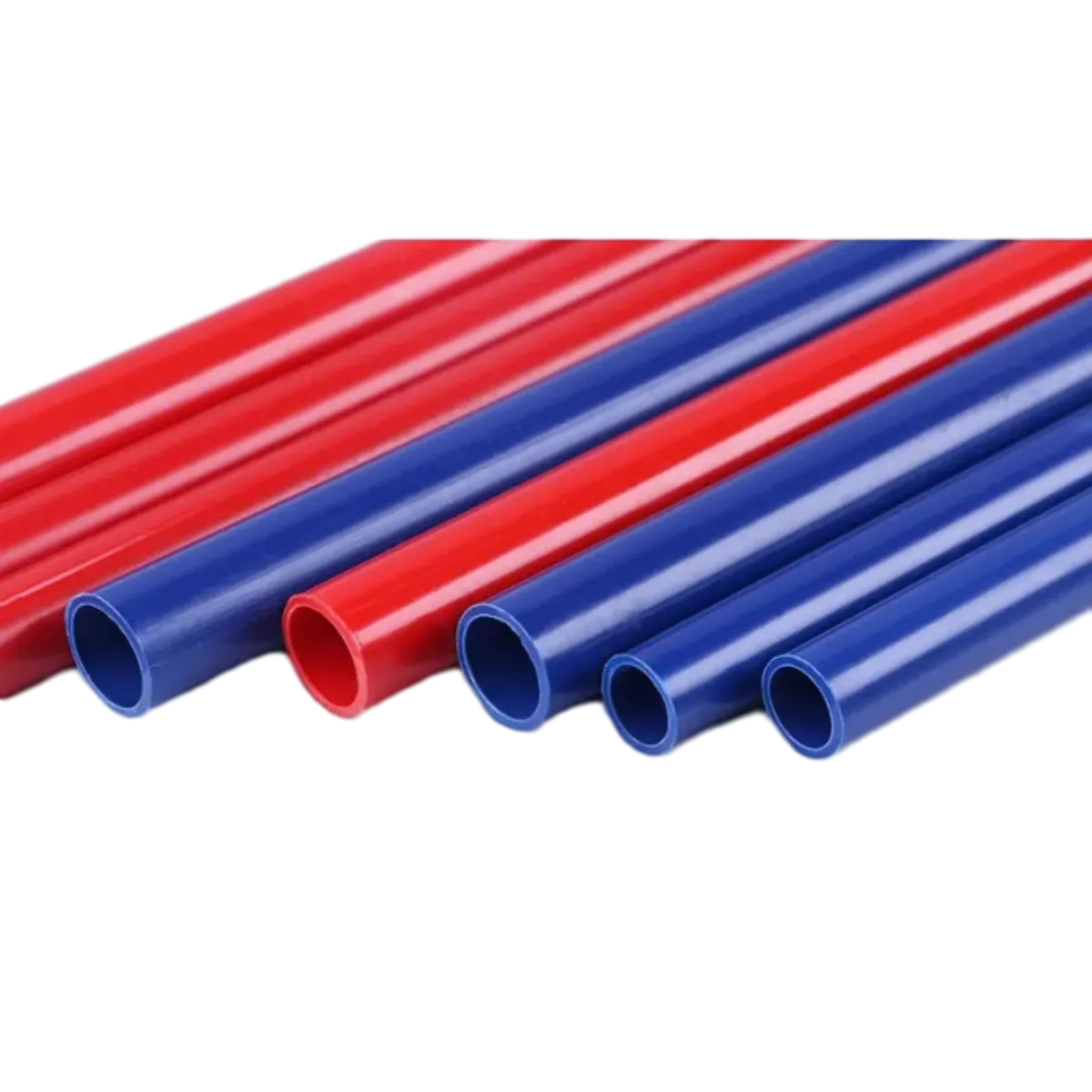

ppr pipes in full factory

Understanding PPR Pipes in Full Factory Settings

PPR pipes, short for Polypropylene Random Copolymer pipes, have gained notable popularity in various industrial applications, particularly in full factory settings. Their unique properties make them an optimal choice for transporting water, chemicals, and other fluids across various processes in manufacturing and other industrial setups. This article will explore the advantages of PPR pipes, their applications in full factories, and the factors that contribute to their widespread adoption.

One of the primary advantages of PPR pipes is their exceptional resistance to corrosion. Unlike metal pipes, which can rust and degrade over time, PPR pipes maintain their integrity even when exposed to harsh chemicals and environments. This durability extends the lifespan of the piping systems in factories, reducing the need for frequent replacements and maintenance—a significant cost-saving measure for manufacturers.

Understanding PPR Pipes in Full Factory Settings

Another important feature is the ease of installation of PPR piping systems. The pipes are lightweight, which simplifies transportation and handling. Furthermore, their jointing process involves the use of heat fusion, which creates seamless connections that enhance the strength of the piping system. This method not only reduces the likelihood of leaks but also speeds up the installation process, contributing to increased operational efficiency in factory settings.

ppr pipes in full factory

The versatility of PPR pipes makes them suitable for a wide range of applications in full factories. They can be utilized for water supply systems, wastewater management, air conditioning, and even in the transportation of various chemicals. Their ability to handle different pressures and flow rates further enhances their applicability in diverse industrial environments.

Environmental considerations are also significant in the selection of materials for factory settings. PPR pipes are recyclable, aligning with the growing trend towards sustainability in manufacturing. Choosing eco-friendly materials not only helps reduce a company’s carbon footprint but can also enhance its reputation among environmentally-conscious consumers.

Moreover, PPR pipes are known for their smooth internal surfaces, which minimize friction and promote efficient flow. This characteristic is particularly beneficial in factory settings, as it reduces energy consumption associated with pumping systems while ensuring optimal performance of fluid transport systems.

In conclusion, the adoption of PPR pipes in full factory settings can be attributed to their numerous advantages, including corrosion resistance, temperature stability, ease of installation, versatility, and environmental benefits. As industries continue to seek efficient and sustainable solutions, PPR pipes will likely remain a popular choice in the landscape of industrial piping systems. Embracing these modern materials not only enhances operational efficiency but also contributes to a greener and more sustainable future in manufacturing.

-

Flexible DN50 HDPE Pipes in Coils: Durable & Easy Install

NewsAug.08,2025

-

DN100 PVC Pipes for Well Casings | Durable & Corrosion-Proof

NewsAug.07,2025

-

Durable DN500 HDPE Double Wall Corrugated Drain Pipes

NewsAug.06,2025

-

32mm HDPE Pipes Coil: Durable & Flexible Water Supply

NewsAug.05,2025

-

DN100 PVC Well Casing Pipes | Durable Corrosion-Proof

NewsAug.04,2025

-

HORON 25mm PPR Plumbing Pipes - AI-Enhanced & Reliable

NewsAug.03,2025