Nov . 21, 2024 10:54 Back to list

hdpe reducer coupling factories

Understanding HDPE Reducer Couplings Insights from Factories

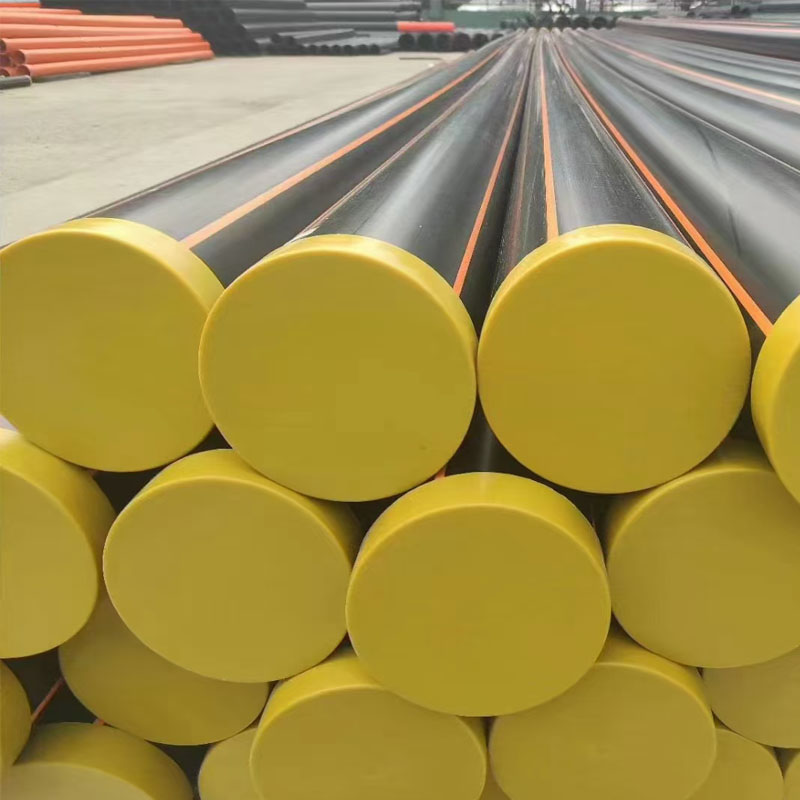

High-Density Polyethylene (HDPE) is a thermoplastic polymer that is widely used in a variety of applications, notably in piping systems. Among the various fittings available in HDPE piping assemblies, the reducer coupling is a key component. This article delves into the intricacies of HDPE reducer couplings, exploring their functions, manufacturing processes, and the factors influencing their production in factories.

Understanding HDPE Reducer Couplings Insights from Factories

The manufacturing process of HDPE reducer couplings involves several steps. Factories typically start with high-quality HDPE resin, which is often produced from natural gas. The resin undergoes extrusion, where it is heated and forced through a mold to create the desired shape. For reducer couplings, precise molding is essential to ensure optimal functionality and compatibility with different pipe sizes.

hdpe reducer coupling factories

Quality control is a significant aspect of the manufacturing process. Factories conduct rigorous testing, including pressure testing and dimensional checks, to ensure that each coupling meets industry standards. Manufacturers often utilize advanced technologies, such as computer numerical control (CNC) machines, to achieve precise dimensions and enhance product consistency.

The demand for HDPE reducer couplings has been on the rise, driven by growing infrastructure projects and an emphasis on sustainable materials. Factories around the globe are adapting to this demand by increasing their production capabilities and investing in research and development. Innovations such as improved HDPE formulations and advanced production techniques are paving the way for more durable and efficient products.

Moreover, the global shift towards environmentally friendly materials has ignited interest in HDPE, as it is 100% recyclable. The sustainability aspect has made HDPE a preferred material in many industries, from water distribution systems to agricultural applications.

In conclusion, HDPE reducer couplings play a crucial role in various piping systems. Understanding the manufacturing processes and factors that influence production in factories is essential for ensuring quality and performance. As industries continue to embrace HDPE for its numerous advantages, the future of reducer couplings looks promising, contributing to more efficient and sustainable infrastructure development. With ongoing advancements in technology and material science, we can expect even greater improvements in the reliability and functionality of HDPE fittings in the years to come.

-

32mm HDPE Pipes in Coil: Durable, Flexible, Easy Install

NewsAug.10,2025

-

140mm PVC Drilling Pipe: Durable & Efficient Well Casings

NewsAug.09,2025

-

Flexible DN50 HDPE Pipes in Coils: Durable & Easy Install

NewsAug.08,2025

-

DN100 PVC Pipes for Well Casings | Durable & Corrosion-Proof

NewsAug.07,2025

-

Durable DN500 HDPE Double Wall Corrugated Drain Pipes

NewsAug.06,2025

-

32mm HDPE Pipes Coil: Durable & Flexible Water Supply

NewsAug.05,2025