Nov . 27, 2024 21:20 Back to list

HDPE Pipe Pricing Overview and Manufacturer Information PDF Guide

Understanding HDPE Pipe Pricing Factors and Overview

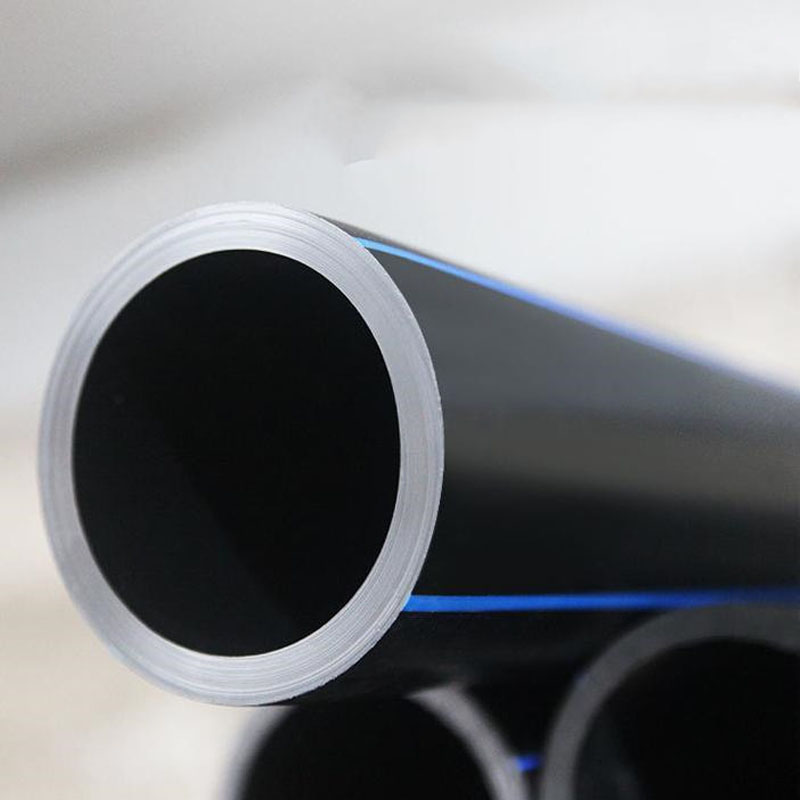

High-Density Polyethylene (HDPE) pipes have gained immense popularity across various industries due to their superior strength, high resistance to corrosion, and lifespan exceeding 50 years. This article examines the pricing factors related to HDPE pipes, often listed in PDFs from manufacturers, and explores why understanding this pricing is crucial for businesses and contractors alike.

What is HDPE Pipe?

HDPE pipes are characterized by their high density, which leads to increased durability and performance capabilities. They are commonly used for water supply, sewage systems, gas distribution, and industrial applications. Their lightweight nature and ease of installation make them a preferred choice over traditional materials such as PVC and metal pipes.

The Importance of Pricing Information

The pricing of HDPE pipes is contingent upon several factors, which is why manufacturers provide detailed price lists, often in PDF format. This transparency helps buyers compare prices from different suppliers and choose products that fit their budget and project specifications.

The primary component in HDPE pipe production is polyethylene resin. The price of this raw material fluctuates based on global oil prices, as it is derived from petroleum. Therefore, any increase in oil prices can lead to a corresponding rise in HDPE pipe prices. Conversely, when oil prices dip, consumers may benefit from lower costs.

2. Production Techniques

Different manufacturers use varying production techniques, which can influence the pricing of their products. Advanced manufacturing processes that enhance pipe strength and flexibility may incur higher costs. For instance, pipes produced through the co-extrusion process may be priced differently than those made using standard extrusion methods.

3. Pipe Specifications

The diameter, wall thickness, and intended application of HDPE pipes significantly affect their pricing. Larger diameter pipes, which are used for substantial water supply projects, typically command higher prices. Similarly, pipes designed for high-pressure applications require more robust manufacturing processes and therefore can be more expensive.

hdpe pipe price list pdf factories

4. Customization and Additives

Many projects require customized HDPE pipes tailored to specific needs. The addition of colors, UV protection, or other additives can drive up the cost. Customization can ensure that pipes meet regulatory standards and provide longer-lasting performance, making it a necessary investment for many projects.

5. Quantity and Bulk Purchasing

Another critical factor in HDPE pipe pricing is the volume of the order. Most manufacturers offer bulk discounts to encourage larger purchases. Understanding these tiered pricing structures can help buyers plan their budgets effectively and investigate the potential for cost savings through bulk buying.

6. Market Demand

The demand for HDPE pipes fluctuates with construction trends, infrastructure development, and environmental regulations. For example, increased focus on sustainable practices has boosted the demand for HDPE in recycling applications and eco-friendly projects, thereby influencing prices. Awareness of market trends can aid buyers in making timely purchasing decisions.

7. Shipping and Handling Costs

Transportation costs are often included in the final pricing of HDPE pipes. Depending on the location of the factory and the distance to the job site, shipping fees can vary significantly. Buyers should consider these extra costs when evaluating price lists to ensure they have a complete understanding of the total expenditure.

Conclusion

Understanding the factors impacting HDPE pipe pricing is essential for engineers, contractors, and purchasing managers involved in construction and plumbing projects. By diligently analyzing price lists provided by manufacturers in PDF formats and considering factors such as material costs, production techniques, specifications, and market demand, buyers can make informed decisions that align with their budget while ensuring compliance with quality standards.

Investing time in understanding these pricing dynamics ultimately leads to better procurement strategies, enhanced project planning, and successful outcomes in various applications where HDPE pipes are utilized. Always remember to consult multiple sources and request detailed price lists to secure the best deals in the competitive marketplace for HDPE pipes.

-

32mm HDPE Pipes in Coil: Flexible & Durable Water Supply

NewsAug.19,2025

-

Flexible 32mm HDPE Pipes in Coil - Durable & Easy Install

NewsAug.18,2025

-

HDPE Sprinkler Pipe Manufacturers - Quality & Durable Solutions

NewsAug.17,2025

-

Durable DN100 PVC Well Casing Pipes for Reliable Water Supply

NewsAug.16,2025

-

HORON 25mm PPR Plumbing Pipes: Durable, Leak-Proof Water Systems

NewsAug.15,2025

-

Durable UPVC Column Pipes for Submersible Pumps | Efficient Water Flow

NewsAug.14,2025