Nov . 29, 2024 10:38 Back to list

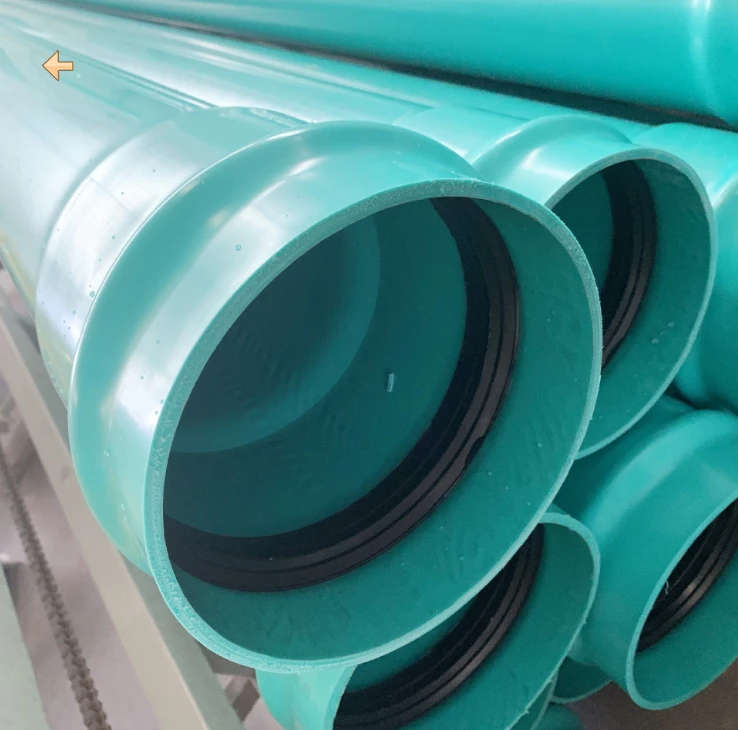

HDPE Pipe Connectors Solutions for Reliable and Efficient Water Management Systems

Understanding HDPE Pipe Connectors and Their Services

High-Density Polyethylene (HDPE) pipes have become increasingly popular in various industries due to their durability, flexibility, and resistance to corrosion. One of the essential aspects of using HDPE pipes is the connectors that join these pipes together, ensuring a robust and secure piping system. This article delves into the significance of HDPE pipe connectors, the various types available, and the services associated with them.

What are HDPE Pipe Connectors?

HDPE pipe connectors are specialized fittings designed to connect sections of HDPE pipes in a manner that maintains the integrity of the pipeline system. These connectors are crucial for various applications, including water supply, drainage, sewage, and industrial piping. The connectors ensure that the joints are watertight and can handle the pressure and stress that the piping system may encounter.

Types of HDPE Pipe Connectors

1. Socket Fusion Connectors These connectors are joined by heating the ends of the pipes and the fitting. The heated surfaces melt slightly, and once they are joined and cooled, they form a strong bond. Socket fusion is advantageous for smaller diameters and is a common method for residential and commercial plumbing.

2. Electro Fusion Connectors These connectors utilize electric heating to fuse the pipe and fitting together. A coil embedded in the fitting heats the material as current flows through it. Electro fusion is particularly effective for larger diameters and is common in industrial applications, providing a reliable and strong joint.

3. Mechanical Connectors These connectors rely on mechanical means to link pipes. They often utilize bolts and clamps to secure the connection. Mechanical connectors offer flexibility, especially when existing pipes need to be joined with new connections or when disassembly may be required.

4. Flanged Connections In this type of connector, flanges are welded onto the pipes, allowing them to be bolted together. Flanged connections are widely used in systems that require maintenance, as they can be easily unbolted for repairs.

5. Transition Fittings These connectors enable the joining of HDPE pipes to other types of materials, such as PVC or metal pipes. This versatility is crucial in a variety of applications where different materials must be integrated into a single system.

hdpe pipe connectors service

Services Related to HDPE Pipe Connectors

Choosing the right HDPE pipe connectors is just one aspect of ensuring a well-functioning piping system. Various services are available to facilitate the installation, maintenance, and repair of HDPE pipe connectors

1. Consultation Services Professional consultants can assess your piping needs and recommend the best types of connectors based on the specific application, material compatibility, and environmental considerations.

2. Installation Services Proper installation is paramount to the longevity of the piping system. Professional services can ensure that the connectors are installed following best practices, which reduces the risk of leaks or failures.

3. Maintenance and Repair Regular maintenance of the piping system, including the connectors, helps prevent unforeseen issues. Professional services can schedule inspections and repairs, ensuring the system operates efficiently.

4. Training and Support Some service providers offer training for in-house maintenance teams. This enables clients to gain insight into proper handling and installation techniques, empowering them to manage minor issues independently.

5. Custom Fabrication For specific needs that standard connectors cannot meet, custom-fabricated connectors can be produced. This service ensures that unique piping configurations and requirements are addressed adequately.

Conclusion

HDPE pipe connectors play a vital role in the integrity and functionality of piping systems across various industries. With different types of connectors and associated services, it is crucial to select the appropriate solution for your specific needs. Whether you are looking for consultation, installation, or ongoing maintenance, partnering with professionals can ensure the reliability and efficiency of your HDPE piping systems, safeguarding your investments for years to come.

-

Hot/Cold DN25 PPR Water Pipes for Kitchen | Durable & Food-Safe

NewsAug.24,2025

-

DN100 PVC Pipes for Well Casings - Durable & Corrosion-Resistant

NewsAug.22,2025

-

HORON 25mm PPR Plumbing Pipes: Durable, Reliable & Leak-Proof

NewsAug.21,2025

-

32mm HDPE Pipes in Coil: Flexible & Durable Water Supply

NewsAug.19,2025

-

Flexible 32mm HDPE Pipes in Coil - Durable & Easy Install

NewsAug.18,2025

-

HDPE Sprinkler Pipe Manufacturers - Quality & Durable Solutions

NewsAug.17,2025