Jun . 14, 2024 06:23 Back to list

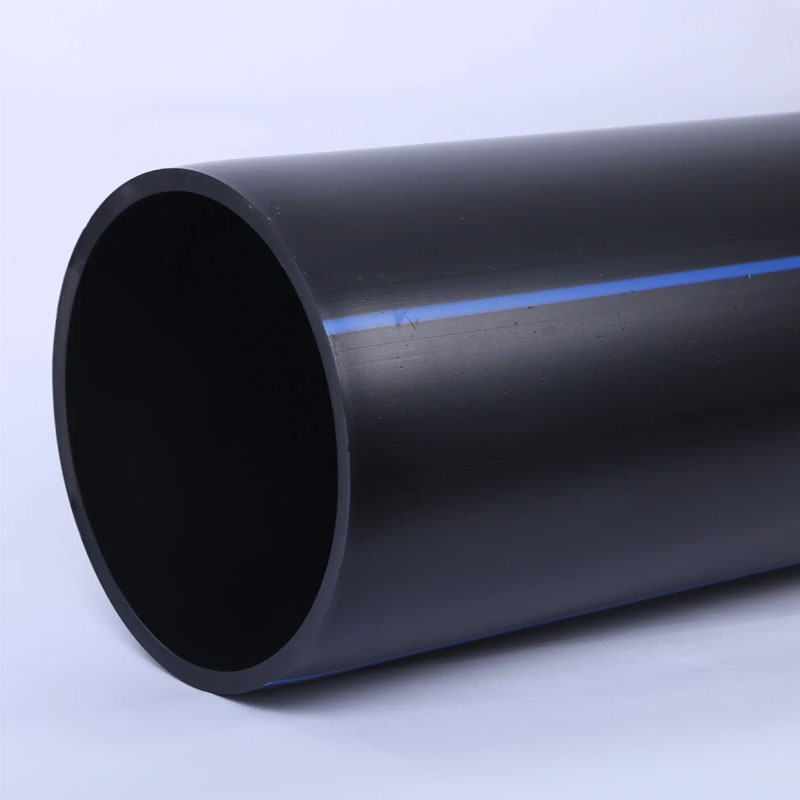

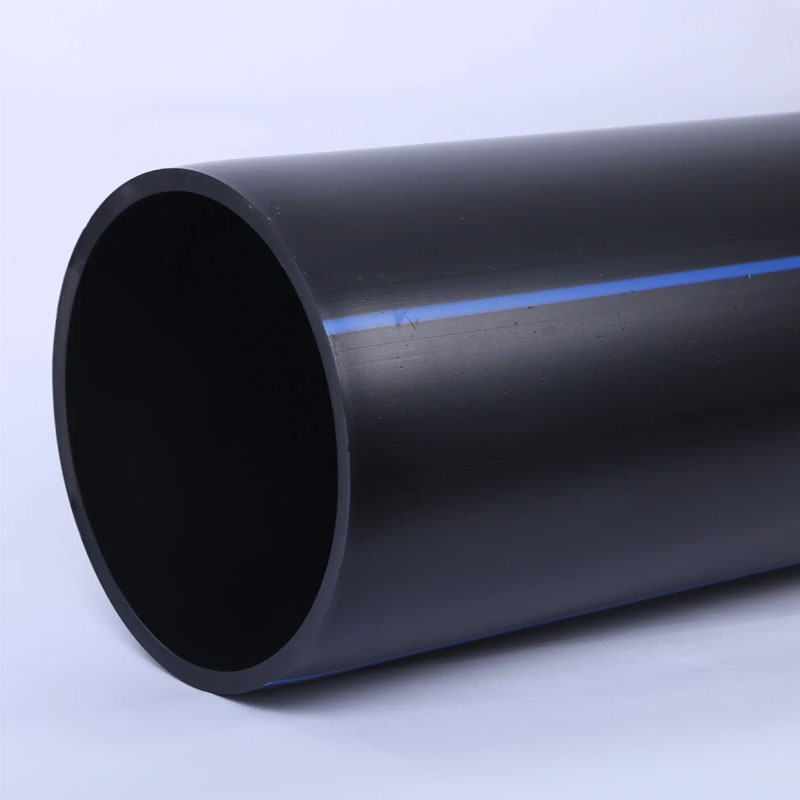

HDPE Pipe Connectors Manufacturer

Simply insert the connector into the end of the pipe and press until it snaps into place Simply insert the connector into the end of the pipe and press until it snaps into place

Simply insert the connector into the end of the pipe and press until it snaps into place Simply insert the connector into the end of the pipe and press until it snaps into place hdpe pipe connectors manufacturer.

When selecting HDPE pipe connectors, it is crucial to consider factors such as compatibility with the pipe material, pressure rating, and environmental conditions. It is also important to ensure that the connectors are manufactured from high-quality materials that can withstand harsh conditions and provide long-lasting performance.

The installation process for HDPE pipe connectors must be carried out with precision and care to ensure the integrity of the pipeline. Proper preparation of the pipes and connectors, including cleaning and inspecting them for any defects, is essential. The use of appropriate tools and techniques, such as torques wrenches for threaded connectors, is also recommended to ensure a secure connection.

In conclusion, HDPE pipe connectors play a vital role in the success of infrastructure projects. By providing a reliable and durable means of joining HDPE pipes, these connectors help to ensure the efficient and safe transportation of fluids. With the right selection, installation, and maintenance, HDPE pipe connectors can contribute significantly to the longevity and functionality of pipelines in both urban and rural settings.

hdpe pipe connectors manufacturer.

When selecting HDPE pipe connectors, it is crucial to consider factors such as compatibility with the pipe material, pressure rating, and environmental conditions. It is also important to ensure that the connectors are manufactured from high-quality materials that can withstand harsh conditions and provide long-lasting performance.

The installation process for HDPE pipe connectors must be carried out with precision and care to ensure the integrity of the pipeline. Proper preparation of the pipes and connectors, including cleaning and inspecting them for any defects, is essential. The use of appropriate tools and techniques, such as torques wrenches for threaded connectors, is also recommended to ensure a secure connection.

In conclusion, HDPE pipe connectors play a vital role in the success of infrastructure projects. By providing a reliable and durable means of joining HDPE pipes, these connectors help to ensure the efficient and safe transportation of fluids. With the right selection, installation, and maintenance, HDPE pipe connectors can contribute significantly to the longevity and functionality of pipelines in both urban and rural settings. -

32mm HDPE Pipes in Coil: Flexible & Durable Water Supply

NewsAug.19,2025

-

Flexible 32mm HDPE Pipes in Coil - Durable & Easy Install

NewsAug.18,2025

-

HDPE Sprinkler Pipe Manufacturers - Quality & Durable Solutions

NewsAug.17,2025

-

Durable DN100 PVC Well Casing Pipes for Reliable Water Supply

NewsAug.16,2025

-

HORON 25mm PPR Plumbing Pipes: Durable, Leak-Proof Water Systems

NewsAug.15,2025

-

Durable UPVC Column Pipes for Submersible Pumps | Efficient Water Flow

NewsAug.14,2025