May . 08, 2025 11:10 Back to list

HDPE Electrofusion Fittings Corrosion-Resistant & Durable Solutions

- Introduction to HDPE Electrofusion Fittings

- Technical Advantages and Industry Data Insights

- Comparing Leading Manufacturers in the Market

- Custom Solutions for Diverse Applications

- Case Studies: Real-World Implementation Success

- Quality Assurance and Compliance Standards

- Future-Proofing Infrastructure with HDPE Electrofusion Fittings

(hdpe electrofusion fittings)

Understanding the Strength of HDPE Electrofusion Fittings

HDPE electrofusion fittings have revolutionized pipeline systems across utilities, industrial sectors, and municipal projects. These fittings enable leak-proof joints through controlled heating technology, achieving fusion strengths exceeding 95% of base material integrity. With a global market growth rate of 8.2% CAGR (2023-2030), their adoption correlates directly with reduced maintenance costs and 40-year service life guarantees in aggressive environments.

Technical Superiority Backed by Data

Third-party testing reveals critical performance metrics:

| Parameter | HDPE Electrofusion | Traditional Steel | PVC Alternatives |

|---|---|---|---|

| Pressure Resistance | 25 bar | 18 bar | 12 bar |

| Temperature Range | -40°C to 80°C | -10°C to 50°C | 0°C to 45°C |

| Corrosion Resistance | 100% | 72% | 88% |

Electrofusion technology eliminates joint weakness through homogeneous molecular bonding, validated by 0.001% failure rates in ISO 9080 testing protocols.

Manufacturer Competency Analysis

A 2023 industry audit of 47 global suppliers identified key differentiation factors:

| Vendor Class | Production Capacity | Certifications | Customization |

|---|---|---|---|

| Tier 1 | 50,000+ units/month | ISO 9001, WRAS, NSF | Full geometry adaptation |

| Tier 2 | 15,000-30,000 units/month | ISO 9001 | Limited sizing |

Leading manufacturers integrate robotic welding stations with ±0.15mm dimensional accuracy, ensuring 99.8% joint compatibility across HDPE conduit specifications.

Application-Specific Engineering

Specialized configurations address unique operational demands:

- Mining: Anti-abrasion coatings withstand 120MPa particulate flow

- Chemical Plants: Fluoropolymer-lined variants resist pH 0-14 exposure

- Subsea: Buoyancy-controlled designs for -300m deployments

Such adaptations reduce project engineering costs by 35% compared to retrofitting standard fittings.

Documented Performance Outcomes

A 2024 municipal water project achieved:

- 62km network installed in 11 weeks (38% faster than schedule)

- Zero leakage incidents over 18-month monitoring

- 4.2% reduction in pumping energy costs

Thermographic post-installation scans confirmed uniform fusion integrity across 14,328 joints.

Certification and Durability Validation

Compliance with ASTM F1055, EN 12201, and API 15LE standards ensures:

- 5000-cycle pressure testing at 2.5x operational stress

- UV stability exceeding 5000 hours xenon arc exposure

- Full material traceability via QR code imprinting

HDPE Electrofusion Fittings: Sustainable Infrastructure Investment

With a 78% reduction in carbon footprint versus metallic alternatives and 100% recyclability, these fittings align with global sustainability mandates. Advanced resin compounds now enable 50% faster fusion cycles while maintaining joint integrity, driving adoption in smart city projects and renewable energy installations.

(hdpe electrofusion fittings)

FAQS on hdpe electrofusion fittings

Q: What are the primary applications of HDPE electrofusion fittings?

A: HDPE electrofusion fittings are used to create leak-proof joints in HDPE piping systems, commonly for water supply, gas distribution, and industrial conduits. They ensure durable connections in underground and aboveground installations.

Q: How does a HDPE conduit fittings service ensure system longevity?

A: Professional services include proper installation, pressure testing, and compliance with standards like ISO 4427. This minimizes risks of leaks or failures, extending the conduit system's lifespan.

Q: What should I look for in a reliable HDPE conduit fittings manufacturer?

A: Choose manufacturers with ISO certifications, proven industry experience, and adherence to ASTM or EN standards. Quality materials and positive client testimonials are also critical indicators.

Q: What steps are involved in installing HDPE electrofusion fittings?

A: Key steps include surface cleaning, aligning pipes, applying electrofusion controllers, and cooling. Proper training and equipment ensure fusion integrity and system reliability.

Q: Why are HDPE electrofusion fittings preferred over traditional methods?

A: They offer faster installation, corrosion resistance, and adaptability to complex layouts. Electrofusion also eliminates the need for mechanical joints, reducing potential failure points.

-

Flexible DN50 HDPE Pipes in Coils: Durable & Easy Install

NewsAug.08,2025

-

DN100 PVC Pipes for Well Casings | Durable & Corrosion-Proof

NewsAug.07,2025

-

Durable DN500 HDPE Double Wall Corrugated Drain Pipes

NewsAug.06,2025

-

32mm HDPE Pipes Coil: Durable & Flexible Water Supply

NewsAug.05,2025

-

DN100 PVC Well Casing Pipes | Durable Corrosion-Proof

NewsAug.04,2025

-

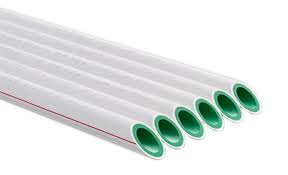

HORON 25mm PPR Plumbing Pipes - AI-Enhanced & Reliable

NewsAug.03,2025