Aug . 12, 2024 16:26 Back to list

Exploring Different Types of PVC Pipe Manufacturers and Their Unique Production Processes

Types of PVC Pipe Factories An Overview

PVC (Polyvinyl Chloride) pipes are a staple in modern infrastructure, used extensively in plumbing, sewage systems, and various industrial applications. The demand for these versatile pipes has led to the establishment of numerous factories that specialize in their production. Understanding the different types of PVC pipe factories can shed light on the manufacturing processes, capabilities, and the products they offer.

1. Injection Molding Factories

One type of PVC pipe factory is the injection molding facility. These factories primarily produce PVC fittings and accessories rather than long pipe lengths. The injection molding process involves heating PVC resin until it melts, then injecting it into molds to form specific shapes, such as elbows, tees, and connectors. This method is highly efficient for producing large volumes of uniform products and is often used to create specialized components that require precise dimensions. Factories focusing on injection molding may serve a wide range of industries, including plumbing, electrical, and telecommunications, providing necessary components that complement main piping systems.

2. Extrusion Factories

Extrusion is the most common manufacturing process for PVC pipes. In this type of factory, PVC resin is fed into an extruder, where it is heated and forced through a die to create continuous lengths of pipe. Extrusion factories can produce pipes of various diameters and thicknesses, catering to different applications. These factories often have advanced machinery capable of producing pipes with specific properties, such as increased durability for high-pressure applications or flexibility for use in residential plumbing systems. Additionally, extrusion factories may offer customization options, such as color-coded piping or specific chemical resistances, to meet industry standards and regulations.

3. Specialty Pipe Manufacturers

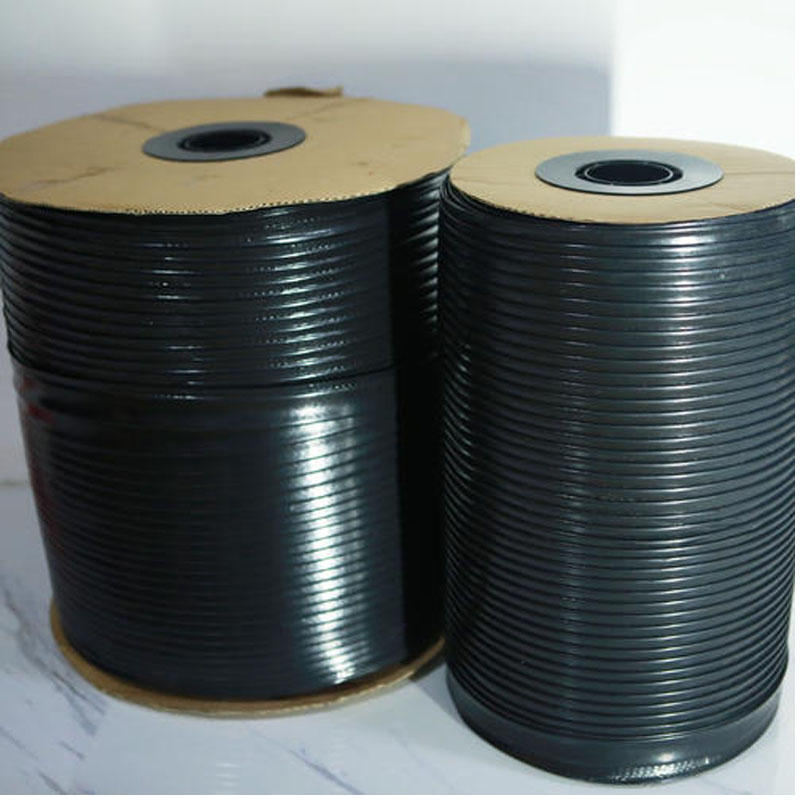

type of pvc pipe factory

Some PVC pipe factories specialize in producing pipes with unique properties or applications. These specialty manufacturers may focus on producing pipes resistant to particular chemicals, high-temperature environments, or pipes designed for specific industries, such as construction or agriculture. For instance, factories might create agricultural drainage pipes that are perforated to allow water infiltration while preventing sediment build-up. These manufacturers often employ cutting-edge technologies and rigorous testing to ensure their products meet high performance standards, making them key players in niche markets.

4. Sustainable PVC Production Facilities

With the increasing focus on sustainability, some PVC pipe factories have adopted environmentally friendly practices. These facilities utilize recycled materials in their production processes or implement energy-efficient technologies to minimize their carbon footprint. By developing eco-friendly PVC options, such as pipes made from recycled PVC (rPVC), these factories appeal to environmentally conscious consumers and industries. This shift helps to address environmental concerns associated with traditional PVC production while still providing high-quality products.

5. Geographically Diverse Factories

PVC pipe factories are situated worldwide, with significant concentrations in regions where construction and plumbing industries thrive. Countries with strong manufacturing bases, such as China, the United States, and Germany, are home to many of the world's leading PVC pipe producers. The location of these factories often impacts shipping costs and lead times for customers, influencing purchasing decisions in local and international markets.

Conclusion

With the variety of types of PVC pipe factories available, each plays a significant role in the supply chain of construction and plumbing materials. From large-scale extrusion plants to specialty manufacturers and environmentally focused facilities, the diversity in production methods and product offerings reflects the growing demands of modern infrastructure. As technology advances and sustainability becomes increasingly prioritized, these factories will continue to evolve, ensuring that they meet the needs of a changing world.

-

HORON 25mm PPR Plumbing Pipes: Durable, Leak-Proof Water Systems

NewsAug.15,2025

-

Durable UPVC Column Pipes for Submersible Pumps | Efficient Water Flow

NewsAug.14,2025

-

DN100 PVC Well Casing Pipes - Durable & Corrosion-Resistant

NewsAug.13,2025

-

Flexible 32mm HDPE Pipes in Coil | Durable Water & Gas Lines

NewsAug.12,2025

-

DN50 HDPE Pipes in Coils: Flexible, Durable & Easy Install

NewsAug.11,2025

-

32mm HDPE Pipes in Coil: Durable, Flexible, Easy Install

NewsAug.10,2025