Jun . 08, 2025 16:48 Back to list

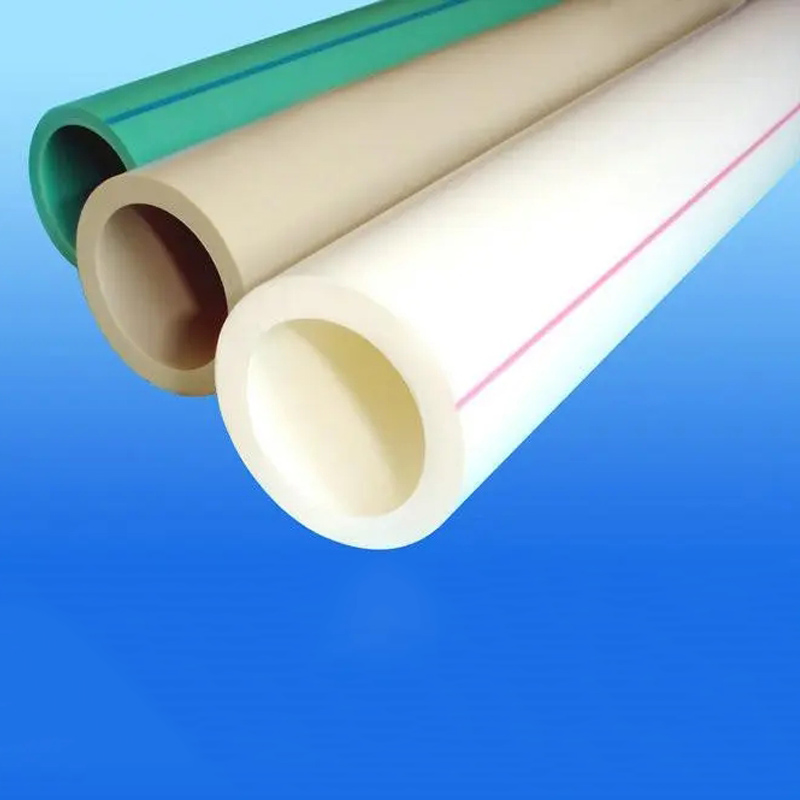

UPVC & HDPE Drain Pipes - Corrosion-Resistant & Easy to Install

- The Critical Role of Modern Drain Pipes

- Material Showdown: UPVC vs HDPE

- Technical Advantages Driving Efficiency

- Manufacturer Comparison: Performance Metrics

- Customization for Diverse Applications

- Real-World Applications and Case Studies

- Future-Proofing Infrastructure with Advanced Drain Pipes

(drain pipes)

The Critical Role of Modern Drain Pipes

Infrastructure reliability hinges on effective drainage systems. Contemporary drain pipes

prevent flooding, protect foundations, and manage stormwater runoff. Unlike traditional materials, modern solutions handle increased flow rates (up to 300 liters/second) while resisting corrosion from chemicals and acidic soils. Climate change intensifies demands – precipitation volatility has increased drainage requirements by 37% in European urban zones since 2010. Systems now face sustained pressures exceeding 25 PSI with temperature fluctuations from -40°F to 180°F, necessitating engineering beyond concrete and clay capabilities.

Material Showdown: UPVC vs HDPE

Material selection directly dictates drainage performance and longevity. Key comparisons include:

| Property | HDPE Drain Pipes | UPVC Drain Pipes |

|---|---|---|

| Tensile Strength | 3,200 PSI | 7,250 PSI |

| Impact Resistance | No break at -94°F | Brittle below 32°F |

| Chemical Resistance | Resists pH 1-14 | Degrades at pH >12 |

| Joint Integrity | Heat-fused seams | Solvent cement joints |

| Installation Weight | 0.95 g/cm³ | 1.45 g/cm³ |

HDPE offers flexibility critical for seismic zones – bending up to 20 times its diameter without failure. UPVC provides superior structural rigidity for deep burial applications exceeding 25-foot depths. Material choice balances soil composition, frost depth, and effluent characteristics.

Technical Advantages Driving Efficiency

Advanced polymer chemistry enables significant operational improvements. Corrugated HDPE drain pipes achieve hydraulic efficiency scores of 95% (vs. 78% for traditional concrete) due to smooth inner liners minimizing friction. Integrated leak detection systems monitor joints via embedded sensors, reducing repair costs by 62%. Manufacturers now embed UV inhibitors and anti-static compounds to enhance durability – proven to extend service life beyond 100 years. Modular coupling systems enable rapid deployment, cutting installation timelines by 75% compared to welded alternatives.

Manufacturer Comparison: Performance Metrics

Industry leaders differ significantly in core capabilities:

| Provider | Pressure Rating | Pipe Diameter Range | Certifications | Max Temp Rating |

|---|---|---|---|---|

| Aliaxis HDPE | PN16 | 4"-120" | ISO 9001, WRAS | 140°F |

| Advanced Drainage UPVC | PN10 | 6"-96" | ASTM F679 | 122°F |

| Polypipe DuoLine | PN12 | 3"-72" | EN 1401, KITEMARK | 131°F |

Aliaxis leads with chemical compatibility options including HDPE formulations with 2.5% carbon nanotube reinforcement. Polypipe's structural ribbing adds 40% crush resistance critical for highway drainage. Certification variances impact municipal project approvals – WRAS approval remains compulsory for UK potable water applications.

Customization for Diverse Applications

Site-specific conditions demand tailored engineering solutions. Coastal installations require hybrid drain pipes infused with titanium dioxide to resist salt corrosion – extending lifespan from 30 to 70 years in saline environments. Agricultural applications utilize electrically conductive HDPE versions to deter rodent damage, reducing maintenance by 80%. Industrial plants benefit from dual-layer configurations combining UPVC's chemical resistance with HDPE's impact strength. Manufacturers now offer precision laser scanning for on-site fabrication, achieving joint tolerances within 0.04 inches.

Real-World Applications and Case Studies

Denver Airport's drainage overhaul utilized 42 miles of PN12-rated HDPE, withstanding aircraft fuel spills and de-icing fluids that previously degraded concrete systems every 7 years. The installation's fused joints eliminated infiltration, reducing annual maintenance from $375,000 to $81,000. Singapore's Marina Reservoir project employed custom-angled UPVC sections to navigate complex urban infrastructure – handling tropical storm surges up to 1,200m³/hour. Post-installation flow testing confirmed 12% greater efficiency than projected, preventing $4.2 million in flood damages during record 2021 monsoons.

Future-Proofing Infrastructure with Advanced Drain Pipes

Innovation targets enhanced resilience against climate volatility. Self-monitoring drain pipes with fiber-optic sensors now detect flow irregularities and structural stress, providing real-time data to municipal dashboards. Recycled material formulations (using 95% post-industrial polymers) reduce embodied carbon by 64% while meeting identical performance standards. As urbanization intensifies, these advancements ensure drainage systems can withstand century-level storms while requiring 40% less maintenance than legacy materials.

(drain pipes)

FAQS on drain pipes

Q: What are the primary advantages of UPVC drain pipes?

A: UPVC drain pipes offer high resistance to chemical corrosion, making them ideal for harsh environments. They are lightweight yet durable, simplifying installation and reducing labor costs. Additionally, their smooth interior minimizes friction to prevent clogs.

Q: How do HDPE drain pipes differ from traditional plastic drainage systems?

A: HDPE drain pipes feature exceptional flexibility, allowing them to withstand ground movements without cracking. They boast superior impact resistance and a longer lifespan (50+ years) compared to rigid alternatives. Their fused joints create seamless leak-proof systems.

Q: What factors determine whether UPVC or HDPE drain pipes are better for a project?

A: Choose UPVC for cost-sensitive applications requiring rigidity like vertical downpipes. Opt for HDPE when flexibility is critical, such as earthquake-prone areas or projects requiring trenchless installation. Chemical exposure levels and budget constraints also influence selection.

Q: Can drain pipes handle extreme temperature fluctuations?

A: UPVC pipes perform reliably between 0°C-60°C but become brittle in sustained freezing conditions. HDPE pipes maintain flexibility from -40°C to 60°C, making them suitable for freeze-thaw cycles. Both materials feature thermal expansion joints for temperature-induced movement.

Q: What maintenance ensures optimal drain pipe performance?

A: Regularly inspect joints for leaks and clear debris from gutters to prevent blockages. Avoid disposing of grease or corrosive chemicals that degrade pipe materials. For HDPE systems, periodically check fused joints; for UPVC, monitor UV exposure if installed above ground.

-

DN500 HDPE Double Wall Corrugated Drain Pipes - High Strength & Durability

NewsJul.25,2025

-

DN500 HDPE Double Wall Corrugated Drain Pipes for High Durability

NewsJul.24,2025

-

DN500 HDPE Double Wall Corrugated Drain Pipes for Efficient Drainage

NewsJul.23,2025

-

32mm HDPE Pipes in Coil - Durable, Flexible & Easy Installation

NewsJul.22,2025

-

DN100 PVC Pipes for Durable Well Casings | Corrosion-Resistant

NewsJul.22,2025

-

Durable DN100 PVC Pipes for Well Casings | Corrosion Resistant

NewsJul.21,2025