Jul . 25, 2025 05:01 Back to list

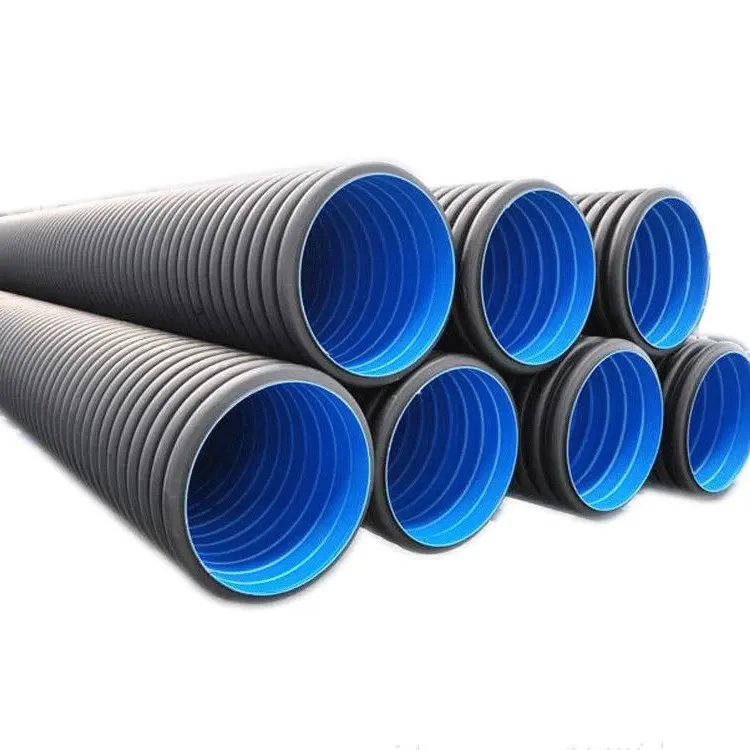

DN500 HDPE Double Wall Corrugated Drain Pipes - High Strength & Durability

Company Profile: HORON INTERNATIONAL

- Enterprise Name: HORON INTERNATIONAL

- Official Website: https://www.horonpipe.com/

- Product URL: DN500 HDPE doule wall corrugated drain pipes

- Email: moddy.zhang@gmail.com

- Phone: +8618632100415

- Address: No.499 West Heping Road, Shijiazhuang City, Hebei Province, China. 050020

Industry Trends and Market Outlook: DN500 HDPE doule wall corrugated drain pipes

Over the past decade, the demand for DN500 HDPE doule wall corrugated drain pipes has surged globally, driven by rapid urbanization, stringent environmental regulations, and the need for durable, cost-effective drainage solutions across municipal, industrial, and agricultural landscapes.

As reported by the Plastic Pipe Institute, global plastic pipe consumption, especially high-density polyethylene (HDPE), grows at over 5% annually. The remarkable features of double wall corrugated HDPE pipes—such as light weight, high ring stiffness, frictionless inner bore, and superior chemical resistance—render them preferable for stormwater, sewage, and culvert projects in both developed and emerging economies (ScienceDirect).

In China and globally, the adoption rate of DN500 HDPE doule wall corrugated drain pipes keeps rising due to their extended lifecycle (exceeding 50 years under regular conditions), recyclability, and reduced installation costs compared to concrete or metal alternatives (ResearchGate). Consequently, these pipes form the backbone of sustainable urban drainage networks for the 21st century.

Product Overview: DN500 HDPE doule wall corrugated drain pipes

Product Name: DN500 HDPE doule wall corrugated drain pipes

Brief Introduction: HORON HDPE DRAIN PIPE is made from premium high-density polyethylene resin and is widely used in both rainwater and sewer drainage systems. The double-wall design offers enhanced ring stiffness, while the smooth inner wall ensures excellent hydraulic performance. These pipes excel in municipal engineering, agricultural irrigation, highway drainage, and infrastructure construction.

Key Advantages:

- Lightweight, easy to transport & install

- Corrosion, abrasion, and chemical resistant

- High flow capacity with smooth interior

- High impact & ring stiffness

- Minimal maintenance & long service life (>50 years)

- Available with a comprehensive range of DN500 HDPE doule wall corrugated drain pipes fittings

Discover more on our product page: DN500 HDPE doule wall corrugated drain pipes

Technical Parameters of DN500 HDPE doule wall corrugated drain pipes

| Technical Parameter | Unit | Standard Value | Typical Value (HORON) | Testing Method |

|---|---|---|---|---|

| Nominal Diameter (DN) | mm | 500 | 500 | ISO 21138-1 |

| Wall Structure | - | Double wall (corrugated outer, smooth inner) | Double wall | GB/T 19472.1-2023 |

| Ring Stiffness (SN) | kN/m² | ≥ 8 (SN8) | ≥ 10 | EN ISO 9969 |

| Pipe Length | m | 6/9/12 (customized) | 6 & 12 | In-house option |

| Inner Wall Roughness | mm | <=0.01 | 0.009 | ISO 4427 |

| Density | g/cm³ | 0.940–0.965 | 0.954 | ISO 1183 |

| Impact Strength | kJ/m² | ≥ 10 | ≥ 11.5 | GB/T 8804.3 |

| Water Tightness | - | No leakage | No leakage | EN 1277 |

Key Applications of DN500 HDPE doule wall corrugated drain pipes

- Municipal Stormwater & Sewer Projects – Drainage systems for cities, towns, and industrial parks.

- Highway & Railway Drainage – Culverts, underpasses, subgrade drainage, and tunnel systems.

- Agricultural Irrigation – Field drainage, irrigation canal linings, and water diversion projects.

- Rainwater Harvesting & Management – Sustainable urban drainage solutions, bioretention and infiltration systems.

- Industrial & Mining – Chemical processing effluent lines, underground cable protection, mining drainage systems.

- Port & Airport Infrastructure – Runoff management and replacement for old concrete/steel piping.

The exceptional properties of DN500 HDPE doule wall corrugated drain pipes make them a first-choice for modern, large-diameter drainage infrastructures—offering sustainability, efficiency, and longevity.

Professional FAQ: Technical Terms around DN500 HDPE doule wall corrugated drain pipes

- Q1: What is the material composition of DN500 HDPE doule wall corrugated drain pipes?

- Answer: These pipes are manufactured from high-density polyethylene (HDPE) resin with a molecular density between 0.940–0.965 g/cm³, ensuring excellent chemical resistance, impact strength, and longevity (Plastic Pipe Institute).

- Q2: What does SN8 mean for corrugated pipes?

- Answer: SN8 indicates a ring stiffness rating of ≥ 8 kN/m², confirming the pipe’s ability to withstand heavy external loads without deformation, suitable for deep burial or trafficked installations.

- Q3: What installation standards apply to DN500 HDPE doule wall corrugated drain pipes?

- Answer: Key standards include ISO 21138-1 and EN 13476 for design and testing, while GB/T 19472.1 and ASTM F2648 guide installation and performance criteria. Proper sand bed preparation and jointing are critical for water tightness.

- Q4: How are DN500 pipes jointed on site?

- Answer: Typically via rubber ring (elastomeric) socket connections, electrofusion, or butt welding—enabling watertight, flexible, and durable connections (PD PolyOne).

- Q5: What are typical pressure and temperature limits?

- Answer: DN500 HDPE doule wall corrugated drain pipes operate in non-pressurized (gravity flow) applications. The working temperature range is -40°C to +60°C, ensuring stability in extreme conditions.

- Q6: Are these pipes certified for potable water transport?

- Answer: While optimized for drainage, these pipes may be manufactured from food-grade HDPE and comply with relevant standards if potable water use is required. Always verify specific certification from the supplier.

- Q7: What is the expected service life?

- Answer: With proper installation and standard operation, the service life exceeds 50 years, outlasting conventional concrete and metal pipes.

Expert Opinion & Future Prospects

With the rapid evolution of infrastructure standards, DN500 HDPE doule wall corrugated drain pipes represent a major leap forward in sustainability, economy, and engineering reliability. As the U.S. Department of Energy observes, HDPE corrugated pipes dramatically reduce installation time, energy consumption, and long-term O&M costs versus legacy drainage pipes—a trend mirrored by recent engineering studies.

HORON INTERNATIONAL leverages advanced extrusion, strict quality control, and international-grade raw materials to produce DN500 HDPE doule wall corrugated drain pipes that set new industry benchmarks. Our global clients trust us for customized solutions engineered to perform, with technical support throughout your entire project life cycle.

- Plastic Pipe Institute. "Industry Overview and Benefits of HDPE Pipes." https://www.plasticpipe.org

- ScienceDirect. "Development and Properties of Corrugated PE Pipes." https://www.sciencedirect.com/science/article/pii/S0959652623032613

- ResearchGate. "Long-term durability of HDPE pipes." https://www.researchgate.net/publication/262964220

- PD PolyOne. "Corrugated Pipe DN500." https://www.pdpolyone.com/products/corrugated-pipe-dn500

- US Department of Energy. "Pipe Materials Comparison." https://www.osti.gov/biblio/1D101242NR0Y24

- ResearchGate. "Performance of HDPE Double Wall Corrugated Pipes." https://www.researchgate.net/publication/325969230_Performance_of_HDPE_Double_Wall_Corrugated_Pipes

-

DN500 HDPE Double Wall Corrugated Drain Pipes for Efficient Drainage

NewsJul.26,2025

-

DN500 HDPE Double Wall Corrugated Drain Pipes for High Durability

NewsJul.24,2025

-

DN500 HDPE Double Wall Corrugated Drain Pipes for Efficient Drainage

NewsJul.23,2025

-

32mm HDPE Pipes in Coil - Durable, Flexible & Easy Installation

NewsJul.22,2025

-

DN100 PVC Pipes for Durable Well Casings | Corrosion-Resistant

NewsJul.22,2025