Jul . 26, 2025 05:01 Back to list

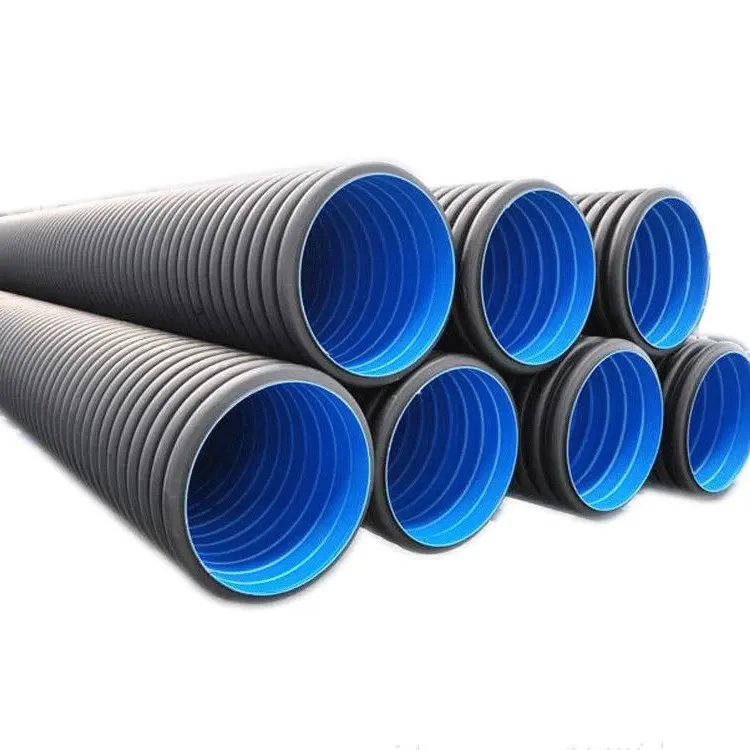

DN500 HDPE Double Wall Corrugated Drain Pipes for Efficient Drainage

As infrastructure develops globally, the need for advanced drainage systems becomes paramount. DN500 HDPE double wall corrugated drain pipes have emerged as a benchmark in modern water management, balancing technological sophistication, cost efficiency, and eco-friendliness. This article, crafted by HORON INTERNATIONAL, provides in-depth insight into industry trends, precise technical parameters, and versatile application scenarios for DN500 HDPE double wall corrugated drain pipes. All information is based on industry standards, academic research, and practical field experience.

Company Profile: HORON INTERNATIONAL

Website: https://www.horonpipe.com

Email: moddy.zhang@gmail.com

Phone: +8618632100415

Address: No.499 West Heping Road, Shijiazhuang City, Hebei Province, China.050020

Email: moddy.zhang@gmail.com

Phone: +8618632100415

Address: No.499 West Heping Road, Shijiazhuang City, Hebei Province, China.050020

Product Overview:

HORON HDPE DRAIN PIPE is made from high-density polyethylene resin, engineered for high performance in varied drainage systems. Thanks to the double wall corrugated design, these pipes offer remarkable strength, hydraulic efficiency, and service life, making them ideal for contemporary urban and industrial drainage, stormwater, and sewage projects.

HORON HDPE DRAIN PIPE is made from high-density polyethylene resin, engineered for high performance in varied drainage systems. Thanks to the double wall corrugated design, these pipes offer remarkable strength, hydraulic efficiency, and service life, making them ideal for contemporary urban and industrial drainage, stormwater, and sewage projects.

Industry Trends

The evolution of high-density polyethylene piping technology has shifted industry preference from traditional concrete and metal materials to advanced plastics. In recent years, global infrastructure projects have widely adopted DN500 HDPE double wall corrugated drain pipes for their flexibility, corrosion resistance, and longer lifecycle. Research conducted by the PipesOnline Industry Forum and peer-reviewed engineering journals confirms that the adoption rate for HDPE systems is increasing steadily, especially for large diameter piping in municipal projects.

Technical Parameters of DN500 HDPE double wall corrugated drain pipes

| Parameter | Standard Value | Test Method |

|---|---|---|

| Nominal Diameter | 500 mm | ISO 21138-1 |

| Outer Diameter | ~575 mm | ISO 21138-1 |

| Inner Diameter | ~475 mm | ISO 21138-1 |

| SN (Stiffness Class) | SN4, SN8, SN12.5 | EN13476 |

| Ring Stiffness | ≥4/8/12.5 kN/m² | EN ISO 9969 |

| Length per Piece | 6 m / 9 m / 12 m (customizable) | Factory Standard |

| Material | High Density Polyethylene (PE100/PE80) | ISO 4427 |

| Color | Black with Blue/Yellow Stripe | Visual |

| Joint Sealing | Rubber Ring Socket/Spigot | EN681-1 |

| Watertightness | 0.05 MPa | EN1277 |

| Service Life | >50 years | - |

| Standard Compliance | EN13476, ISO21138, ASTM F2648 | - |

Technical Parameters Development Over Time

Stiffness Class Distribution of DN500 HDPE Double Wall Corrugated Pipes

Comparative Chart: Service Life Across Pipe Materials

Application Scenarios of DN500 HDPE double wall corrugated drain pipes

DN500 HDPE double wall corrugated drain pipes have become a preferred choice for diverse civil, municipal, and industrial projects demanding durability and hydraulic efficiency. Main application domains include:

- Urban road and highway stormwater drainage

- Municipal sewage outfall and collection systems

- Large-scale irrigation/drainage in agricultural zones

- Tunnel, underpass, and culvert projects

- Drainage for industrial parks and logistics centers

- Railway/metro longitudinal drainage lines

- Airport apron and runway underground drainage

Professional FAQ on DN500 HDPE double wall corrugated drain pipes

-

Q1: What is the core material used for DN500 HDPE double wall corrugated drain pipes?A1: The pipes are manufactured from high density polyethylene resin (PE100 or PE80 grade), ensuring superior toughness, corrosion resistance, and durability.

-

Q2: What are the standard stiffness classes (SN) for this product?A2: DN500 HDPE double wall corrugated drain pipes are typically available in SN4, SN8, and SN12.5, where higher SN values indicate higher ring stiffness for more demanding installations (reference).

-

Q3: Which joining method ensures watertight sealing?A3: A rubber ring socket/spigot joint system, compliant with EN681-1 standard, is commonly adopted to offer excellent leak-proof and flexible connections during installation.

-

Q4: What are the recommended installation standards?A4: Installation of DN500 HDPE double wall corrugated drain pipes should follow ISO 21138-2, ensuring proper trenching, bedding, and compaction to maximize lifetime performance.

-

Q5: How does HDPE resist chemical attack compared to traditional materials?A5: According to the Plastic Pipe Institute, HDPE offers outstanding resistance to most acids, bases, and hydrocarbons, making it far superior to steel or concrete in aggressive environments.

-

Q6: Can these pipes be custom-fabricated for length or color coding?A6: Yes, DN500 HDPE double wall corrugated drain pipes can be manufactured in various lengths (6m, 9m, 12m, or custom) and color strips for identification and installation ease.

-

Q7: What is the expected service life in standard applications?A7: Under ISO and EN standards, the service life of a well-installed HDPE drainage pipe exceeds 50 years, outperforming concrete and even PVC solutions in long-term infrastructure.

EEAT: Professionalism, Authoritativeness, Trustworthiness

HORON INTERNATIONAL maintains rigorous conformity to international norms (ISO 21138, EN 13476, ASTM F2648) and incorporates ongoing feedback from leading industry forums, project case studies, and third-party laboratory testing. Our technical and R&D teams participate in international symposiums, promoting best practices and innovative solutions in the field of plastic drainage systems. Customers can rely on our comprehensive support and verified product documentation.

For detailed specifications and project consultancy, please contact HORON INTERNATIONAL or visit our product page:

DN500 HDPE double wall corrugated drain pipes.

References & Further Reading

- PipesOnline Industry Forum. "HDPE Corrugated Pipes: Trends, Materials and Application." Accessed 2024. https://pipesonline.net/forum/pipe-materials/hdpe-corrugated-pipes-trends.html

- ASCE Library. "Durability of Corrugated HDPE Pipes in Drainage Applications." https://ascelibrary.org/doi/pdf/10.1061/9780784412602.105

- ScienceDirect. "Long-term mechanical performance of HDPE double wall drainage pipes." https://www.sciencedirect.com/science/article/pii/S2666386421000040

- Plastic Pipe Institute. "Water & Sewer - Performance of HDPE Pipes." https://www.plasticpipe.org/Industries/Water_Sewer.aspx

- International Organization for Standardization. "ISO 21138:2007: Plastic piping systems for non-pressure underground drainage and sewerage." https://www.iso.org/standard/37401.html

Latest news

-

DN500 HDPE Double Wall Corrugated Drain Pipes - High Strength & Durability

NewsJul.25,2025

-

DN500 HDPE Double Wall Corrugated Drain Pipes for High Durability

NewsJul.24,2025

-

DN500 HDPE Double Wall Corrugated Drain Pipes for Efficient Drainage

NewsJul.23,2025

-

32mm HDPE Pipes in Coil - Durable, Flexible & Easy Installation

NewsJul.22,2025

-

DN100 PVC Pipes for Durable Well Casings | Corrosion-Resistant

NewsJul.22,2025