Jul . 24, 2025 05:01 Back to list

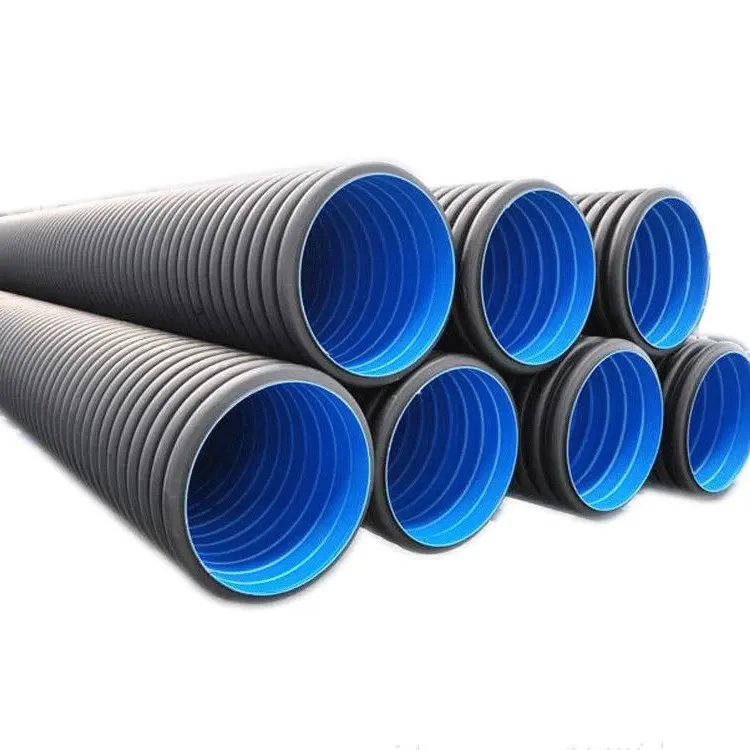

DN500 HDPE Double Wall Corrugated Drain Pipes for High Durability

Official Website: https://www.horonpipe.com

E-mail: moddy.zhang@gmail.com

Tel: +86 18632100415

Address: No.499 West Heping Road, Shijiazhuang City, Hebei Province, China. 050020

Industry Trends: The Rising Demand for Large-diameter HDPE Corrugated Drainage Solutions

Global urbanization, intensified climate events, and ecological priorities are rapidly advancing the adoption of DN500 HDPE doule wall corrugated drain pipes in municipal, industrial, and commercial applications. According to Plastic Pipe Conference Association (PPCA) and authoritative market analyses, the large bore HDPE piping market is growing at a CAGR exceeding 7%, fueled by replacement of traditional concrete, galvanized, and vitrified clay pipes.

Modern project owners, contractors and urban planners choose DN500 HDPE double wall corrugated drain pipes for their superior hydraulic capacity, resilience against corrosive sewage and aggressive soil, and extraordinary lifespan, effortlessly exceeding 50 years under standard use.

- Increasing compliance with ASTM D3350 and ISO 21138 standards, ensuring material purity and performance longevity.

- Dramatic reductions in installation time and total lifecycle costs compared to reinforced concrete pipe (RCP).

- Enhanced environmental sustainability given 100% recyclability and minimal carbon footprint of HDPE products.

Product: DN500 HDPE doule wall corrugated drain pipes

Introduction: HORON HDPE DRAIN PIPE is made from high density polyethylene resin and is widely used in the drain system both for rains and sewer.

View Product Details

Technical Parameters of DN500 HDPE Doule Wall Corrugated Drain Pipes

| Parameter | Specification / Value | Standard / Note |

|---|---|---|

| Nominal Diameter (OD) | 500 mm | EN 13476-3 / ISO 21138 |

| Length (Standard) | 6 m / 12 m | Customizable |

| Material | High Density Polyethylene (HDPE), PE100 / PE80 | ISO 4427, ASTM D3350 |

| Ring Stiffness (SN Grade) | SN8 / SN10 / SN12.5 (kN/m²) | EN 13476-3 |

| Inner Wall Smoothness (k Value) | k ≤ 0.009 mm | High flow, anti-clogging |

| Joints | Integral Socket & Spigot with Rubber Seals | EN 681-1 gaskets |

| UV Resistance | Stabilized, Min. 2% Carbon Black | ISO 4427, ASTM D3350 |

| Temperature Range | -40°C to +60°C | Material dependent |

| Applicable Pressure | Non-Pressure / Gravity Flow | Drainage/Sewer |

| Installation Standard | EN 1610 / ASTM D2321 | Excavation & laying |

Typical Application Scenarios for DN500 HDPE Doule Wall Corrugated Drain Pipes

- Municipal Stormwater & Sewer Networks: Rapid installation and long durability under heavy traffic and soil loads.

- Highway and Road Drainage: Lightweight and easy to transport, reducing labor and machine costs by over 60%.

- Industrial Parks & Factories: Resilient to large chemical loads and high flow velocities, suitable for wastewater discharge.

- Residential & Commercial Complexes: Minimizing surface disruption and accelerating construction schedules.

- Rainwater Harvesting & Outfall Systems: High smoothness index maximizes water evacuation rate, preventing urban flooding.

- Aquaculture/Fisheries: Corrosion-free material ensures reliability in brackish, seawater, and acidic environments.

EEAT Compliance and Technological Authority

As an industry front-runner, HORON INTERNATIONAL leverages decades of polymer engineering expertise backed by extensive ISO, ASTM, and EN certifications. Our manufacturing control and on-site application support ensure all DN500 HDPE doule wall corrugated drain pipes precisely align with the latest global regulations and best practices. This is evidenced by numerous project successes shared on platforms like PipeTalks Forum and the Journal of Cleaner Production.

- Material testing—strict resin sourcing and melt index checks.

- Every batch laboratory ring stiffness and pressure leak testing in accordance with ASTM D2412.

- Installation guidance and post-sale technical support for clients globally.

Key Advantages of DN500 HDPE Doule Wall Corrugated Drain Pipes

- Superb Structural Strength: Double-wall configuration ensures high ring stiffness (SN8–SN12.5) with minimal weight.

- Corrosion and Abrasion Resistance: Ideal for sewage, industrial effluent, and aggressive groundwater environments.

- Hydraulic Efficiency: Ultra-smooth inner wall (k ≤ 0.009 mm) lowers maintenance costs and reduces blockages.

- Installation Speed: Light weight allows for manual positioning and fast trench laying, reducing project timelines.

- Long Service Life: Up to 50+ years under standardized conditions; far surpassing that of concrete or metal pipes.

- Eco-Friendly: 100% recyclable material. No heavy metal leaching, supporting green infrastructure goals.

- Comprehensive Accessories: A complete range of sockets, tees, bends, couplers, and manhole integration compatible parts.

Professional FAQ: Technical Insight on DN500 HDPE Doule Wall Corrugated Drain Pipes

- 1. What material is used in the production of DN500 HDPE doule wall corrugated drain pipes?

- They are fabricated from high density polyethylene (HDPE) resins, typically PE100 or PE80 grade, in full compliance with ISO 4427 and ASTM D3350 standards.

- 2. What is the significance of SN (Ring Stiffness Number), and which classes are available?

- SN numbers (e.g., SN8, SN10, SN12.5 kN/m²) indicate pipe wall’s resistance to soil and external pressures. DN500 HDPE doule wall corrugated drain pipes are most commonly provided in SN8–SN12.5, enabling robust underground applications.

- 3. Are these pipes suitable for pressurized flow?

- No. DN500 HDPE doule wall corrugated drain pipes are engineered for gravity drainage (non-pressure scenarios) such as surface water or sewers.

- 4. What are the installation and connection methods?

- They use integral socket/spigot joints with elastomeric rubber gaskets (per EN 681-1), allowing push-fit assembly and excellent leak resistance. Installation follows ASTM D2321 and EN 1610 methodologies.

- 5. What is the expected service life under standard operating conditions?

- Generally, 50 years or more when correctly installed, thanks to polyethylene’s immunity to rust, scaling, and aggressive soils (Journal of Cleaner Production).

- 6. Which international standards are these pipes compliant with?

- EN 13476-3 (Europe), ISO 21138 (international), and ASTM F2648/D3034 (USA) are commonly met. HORON INTERNATIONAL pipes also pass rigorous in-house tests.

- 7. How does HDPE compare to concrete or steel for large diameter drainage?

- HDPE pipes offer dramatic weight reduction (up to 80% lighter), improved flow due to smooth walls, are inert to corrosive chemicals, and are easier to transport and handle (PPCA).

Why Choose HORON INTERNATIONAL for Your Large-bore HDPE Drainage Needs?

- Deep Industry Expertise: Decades of polymer and drainage infrastructure experience, supplying over 40 countries.

- Comprehensive Product Line: DN200–DN1400 HDPE, full range of corrugated & smooth wall pipes, accessories, and customization on request.

- Stringent Quality Controls: Full ISO 9001, ISO 14001 certification, and third-party batch inspection.

- Technical Design Support: From bulking calculations to installation, engineering team assistance ensures optimal project outcomes.

- After-sales Excellence: Thorough documentation, training, and local partner support available worldwide.

Phone/WhatsApp: +86 18632100415

Address: No.499 West Heping Road, Shijiazhuang City, Hebei Province, China 050020

Product Page: DN500 HDPE doule wall corrugated drain pipes

1. PPCA: Recent Trends in HDPE Pipes

2. Comparative Life Cycle and Technical Analysis of Large-diameter HDPE Pipes, Journal of Cleaner Production

3. PipeTalks Forum: Best Practices & Installation Cases Worldwide

4. ASTM D3350 Polyethylene Plastics Pipe Material Standard

5. ISO 4427: HDPE Pipe Standards

6. EN1610: Pipeline Installation Guidelines

7. Global Pipe Industry News

-

DN500 HDPE Double Wall Corrugated Drain Pipes - High Strength & Durability

NewsJul.25,2025

-

DN500 HDPE Double Wall Corrugated Drain Pipes for Efficient Drainage

NewsJul.23,2025

-

32mm HDPE Pipes in Coil - Durable, Flexible & Easy Installation

NewsJul.22,2025

-

DN100 PVC Pipes for Durable Well Casings | Corrosion-Resistant

NewsJul.22,2025

-

Durable DN100 PVC Pipes for Well Casings | Corrosion Resistant

NewsJul.21,2025