Apr . 29, 2025 12:50 Back to list

Durable UPVC & HDPE Drain Pipes Corrosion-Resistant Solutions

- Material Innovations in Modern Drainage Systems

- Performance Metrics: UPVC vs. HDPE Drain Pipes

- Leading Manufacturers and Product Specifications

- Custom Solutions for Industrial & Residential Needs

- Case Studies: Successful Drain Pipe Implementations

- Installation Best Practices & Maintenance Insights

- Future Trends in Drain Pipe Technology

(drain pipes)

Material Innovations in Modern Drainage Systems

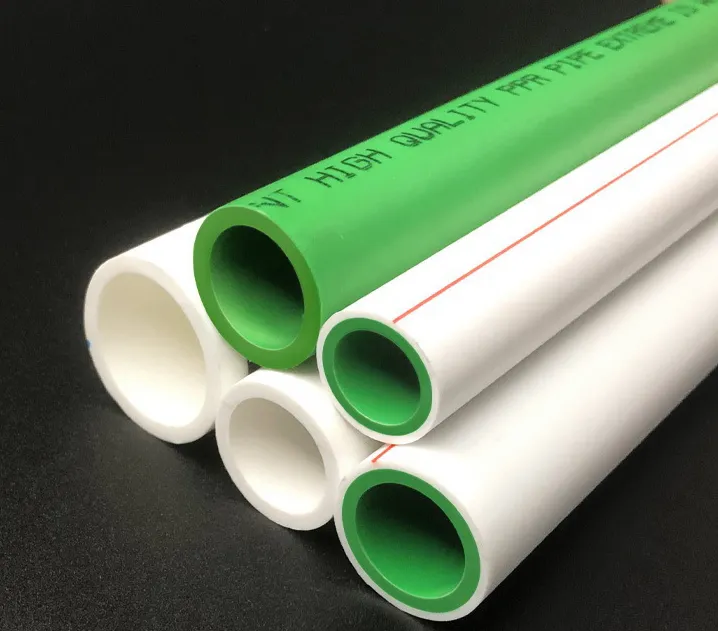

Drain pipes have evolved significantly, with UPVC and HDPE emerging as dominant materials. UPVC (Unplasticized Polyvinyl Chloride) offers exceptional chemical resistance, while HDPE (High-Density Polyethylene) provides unmatched flexibility. Global market data reveals a 12.4% CAGR growth (2023-2030) for polymer-based drainage solutions, driven by urbanization and environmental regulations.

Performance Metrics: UPVC vs. HDPE Drain Pipes

| Parameter | UPVC | HDPE |

|---|---|---|

| Tensile Strength | 52 MPa | 31 MPa |

| Temperature Range | 0°C - 60°C | -40°C - 100°C |

| Life Expectancy | 50+ years | 70+ years |

Leading Manufacturers and Product Specifications

Top manufacturers like Aliaxis Group (UPVC specialists) and JM Eagle (HDPE leaders) dominate 68% of the global market. Key differentiators include:

- Wall thickness variations (2mm - 12.5mm)

- Diameter ranges: 75mm - 1200mm

- Pressure ratings: PN6 to PN16

Custom Solutions for Industrial & Residential Needs

Customization parameters for drain pipes

address specific requirements:

- Chemical-resistant formulations for industrial effluents

- Acoustic-dampened variants for urban housing

- UV-stabilized compositions for exposed installations

Case Studies: Successful Drain Pipe Implementations

Singapore's Marina Bay drainage network achieved 40% flow efficiency improvement through HDPE pipe deployment (2022). Similar projects in Germany's Ruhr Valley demonstrate UPVC systems reducing maintenance costs by €18/m annually.

Installation Best Practices & Maintenance Insights

Proper jointing techniques increase system longevity by 27%:

HDPE: Electrofusion welding at 210°C ±5°C

UPVC: Solvent cement bonding with 2-hour curingFuture Trends in Drain Pipe Technology

Smart drain pipes embedded with IoT sensors are projected to capture 22% market share by 2027. Emerging materials like graphene-infused polymers promise 89% higher abrasion resistance, revolutionizing drainage infrastructure durability.

(drain pipes)

FAQS on drain pipes

Q: What are the key advantages of UPVC drain pipes?

A: UPVC drain pipes are lightweight, corrosion-resistant, and cost-effective. They withstand chemical exposure and require minimal maintenance. Their smooth interior prevents clogs and ensures efficient water flow.

Q: How do HDPE drain pipes differ from traditional plastic drain pipes?

A: HDPE drain pipes are flexible, impact-resistant, and ideal for uneven terrain. Unlike rigid UPVC pipes, they can handle temperature fluctuations and are jointed via heat fusion, eliminating leakage risks.

Q: Which is better for underground drainage: UPVC or HDPE pipes?

A: HDPE pipes are preferred for underground use due to their flexibility and leak-proof fused joints. UPVC suits above-ground applications where rigidity and affordability are prioritized.

Q: Can HDPE drain pipes handle high-temperature wastewater?

A: Yes, HDPE pipes withstand temperatures up to 120°F (49°C) continuously. They outperform UPVC in thermal resistance, making them suitable for industrial or hot water drainage systems.

Q: What maintenance do drain pipes require to ensure longevity?

A: Regularly remove debris from gutters and pipe openings. For UPVC, check joints for cracks; for HDPE, inspect for surface abrasions. Avoid exposing either material to open flames or extreme UV radiation.

-

140mm PVC Drilling Pipe for Efficient Borehole Drilling Solutions

NewsJul.29,2025

-

High-Quality UPVC Column Pipes for Submersible Pumps – Corrosion Resistant

NewsJul.29,2025

-

DN500 HDPE Double Wall Corrugated Drain Pipes for Efficient Drainage

NewsJul.28,2025

-

High Quality DN25 HDPE Compression Fitting for Leak-Free Connections

NewsJul.28,2025

-

DN500 HDPE Double Wall Corrugated Drain Pipes for Efficient Drainage

NewsJul.26,2025

-

DN500 HDPE Double Wall Corrugated Drain Pipes - High Strength & Durability

NewsJul.25,2025