Mar . 07, 2025 03:42 Back to list

hdpe sprinkler pipe manufacturers

Authoritativeness in the production process is another pillar that fortifies the reliability of column pipes. Reputable manufacturers abide by stringent industry standards and rigorous testing protocols to ensure their products meet the high-pressure demands of submersible pumps. Companies that invest in certification and endorsement by recognized bodies such as the American National Standards Institute (ANSI) or the International Organization for Standardization (ISO) display a commitment to upholding quality — a facet that buyers should not overlook. In the real world, experience has shown that maintenance and monitoring are integral to the trustworthiness of a column pipe system. The gradual degradation of materials due to environmental factors or operational stresses is a genuine concern. Regular inspections and preventive maintenance checks can preempt potential failures. Ensuring that fittings remain tight, and that there are no visible signs of corrosion or damage, prolongs the life and efficiency of the system, reinforcing trust in the solution provided. To tie these elements together, efficient systems stem from informed choices not only in terms of products but also in the knowledge of the professionals involved. Engaging with specialists who possess a thorough understanding of not just the product specifications but also the environmental and operational dynamics is invaluable. These professionals can anticipate challenges and propose solutions that uniquely cater to individual project needs, thereby guaranteeing performance. Ultimately, the landscape of submersible pump service and column pipes is one that thrives on a robust integration of innovative technology, expert craftsmanship, and stringent quality measures. In an increasingly competitive market, where each component must complement the other seamlessly, possessing comprehensive knowledge and fostering a reputation built on Experience, Expertise, Authoritativeness, and Trustworthiness will distinguish the exceptional from the adequate. By prioritizing these aspects, one not only ensures the success of their immediate water management endeavors but also contributes to a sustainable and reliable hydrological practice that stands the test of time.

-

DN25 PPR Water Pipes for Kitchen - Durable & Leak-Proof Plumbing Solution

NewsJul.30,2025

-

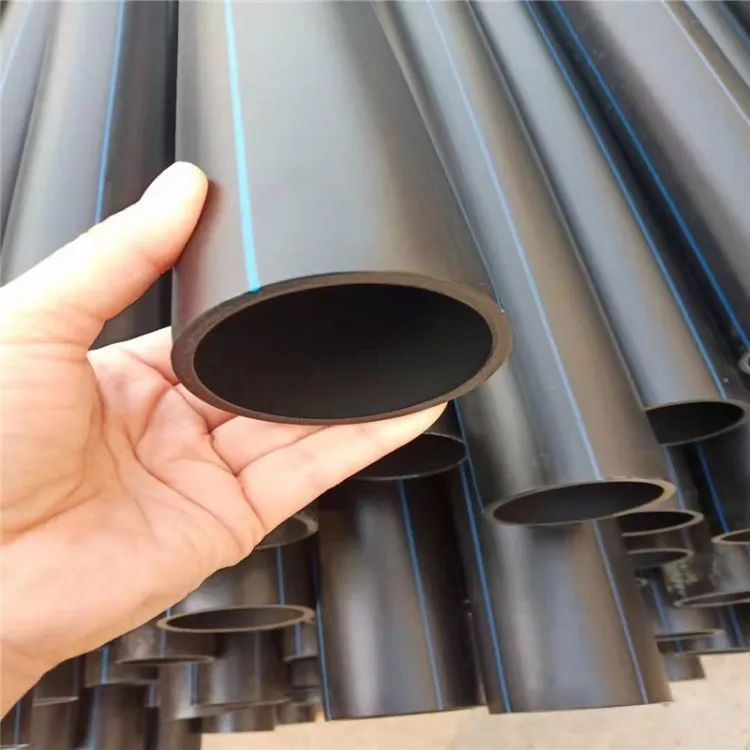

HDPE Sprinkler Pipe Manufacturers – Durable Irrigation Solutions

NewsJul.30,2025

-

High-Quality DN150 HDPE Pipes for Gas Delivery – Durable & Leak-Proof

NewsJul.29,2025

-

140mm PVC Drilling Pipe for Efficient Borehole Drilling Solutions

NewsJul.29,2025

-

High-Quality UPVC Column Pipes for Submersible Pumps – Corrosion Resistant

NewsJul.29,2025

-

DN500 HDPE Double Wall Corrugated Drain Pipes for Efficient Drainage

NewsJul.28,2025