Mar . 07, 2025 03:09 Back to list

hdpe sprinkler pipe manufacturers

Expert knowledge and continual technological advancements drive our research and development processes, ensuring our products remain at the forefront of the industry. The comprehensive testing protocols applied to each pipe before it leaves our factory guarantee that only those meeting our rigorous standards reach the market. Every batch is subject to hydrostatic and tensile strength tests, alongside endurance evaluations simulating long-term use under stress conditions. Such meticulous attention to detail underscores our commitment to quality and reliability. As connoisseurs in the field, our factory not only prioritizes product excellence but also customer education. Understanding the system’s requirements empowers you to maintain and operate your pumping system effectively, extending its lifespan and ensuring a swift return on investment. We offer technical guidance and support, combining our expertise with the latest technological tools to provide solutions that are not only efficient but also economically viable. Trustworthiness is woven into the very fabric of our business operations. By adhering to ethical business practices and transparent communication, we build lasting relationships with our clients. Our track record speaks volumes – with countless successful installations around the world, our clients consistently express satisfaction with both the durability of our products and the efficacy of our service. In conclusion, selecting the right column pipe is a high-stakes decision affecting both the immediate efficiency and the long-term sustainability of submersible pump systems. By leveraging advanced materials, custom solutions, and cutting-edge technology, we ensure that our products meet the high demands inherent in these applications. With a focus on expertise, reliability, and transparency, our factory stands as a trusted partner in delivering column pipes that guarantee peak performance for any submersible pump system.

-

DN25 PPR Water Pipes for Kitchen - Durable & Leak-Proof Plumbing Solution

NewsJul.30,2025

-

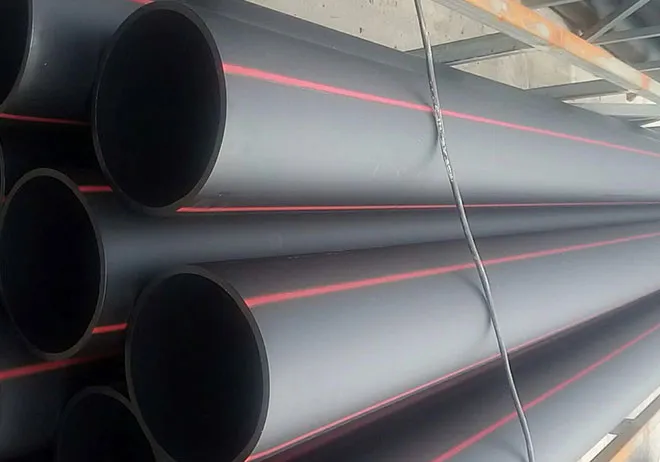

HDPE Sprinkler Pipe Manufacturers – Durable Irrigation Solutions

NewsJul.30,2025

-

High-Quality DN150 HDPE Pipes for Gas Delivery – Durable & Leak-Proof

NewsJul.29,2025

-

140mm PVC Drilling Pipe for Efficient Borehole Drilling Solutions

NewsJul.29,2025

-

High-Quality UPVC Column Pipes for Submersible Pumps – Corrosion Resistant

NewsJul.29,2025

-

DN500 HDPE Double Wall Corrugated Drain Pipes for Efficient Drainage

NewsJul.28,2025