Mar . 13, 2024 10:15 Back to list

PPR PIPES-Types of HDPE Pipe Fusion

HDPE piping provides durable, long-lasting options for many piping applications. Highly customizable, HDPE piping can be applied using various pipe sizes and fusion techniques. These fusion techniques make HDPE piping unique, allowing long pipe stretches to connect and maneuver through complex spaces. US FUSION provides tailored solutions to meet your needs through HDPE pipe fusion.

What Is Pipe Fusion?

In most piping applications, a single section of HDPE pipe will not get the job done. When multiple pieces of pipe are needed, HDPE pipe fusion comes in. While there are many types of HDPE pipe fusion, each involves heating the pipe and applying pressure to fuse two pieces together. In doing so, HDPE pipe fusion ensures long stretches of pipe are securely fused, resulting in a continuous, sealed connection.

At US FUSION, our on-site plastic fusion team is highly skilled in HDPE pipe fusion methods. Whether your piping is underground or exposed, we focus on safety for both our crew and for the environment. We’ll ensure your pipe connections are strong and sealed properly, keeping unwanted elements out of the environment — all while meeting the highest industry standards and environmental regulations.

4 Types of HDPE Pipe Fusion

Not sure what fusion method is needed for your project? We’ve got you covered. Below we’ll break down HDPE pipe fusion and application methods.

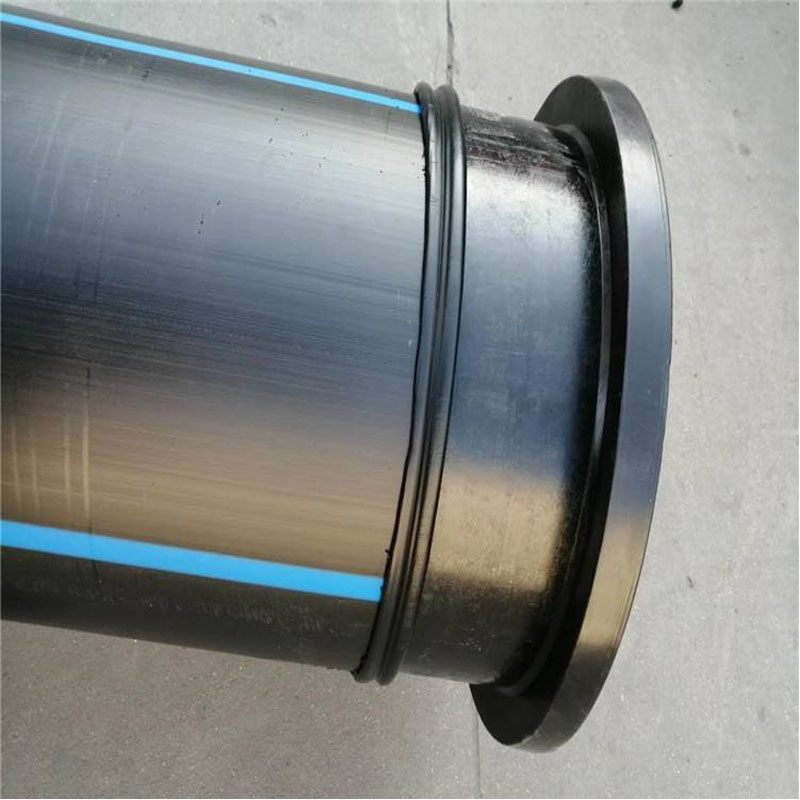

Butt Fusion

Butt fusion is used when two straight pieces of pipe need to be fused together. Butt fusion is the most common and best pipe fusion method. In this method, a fusion machine holds two pieces of pipe while the ends are heated with a heater plate. Once heated, force is used to push the two ends together where they are left to cool. After the cooling process is complete, the two pieces of pipe are firmly connected and sealed. The butt fusion weld will then be stronger than the pipe.

Electrofusion

Electrofusion is used in tight spaces and with fittings where butt fusion cannot be used. Electrofusion couplers are needed to make this fusion connection. In this method, electrofusion couplers have copper coils inside the coupler that are then heated up to fuse to the pipe together to create a tight seal.

Socket Fusion

When flexibility is vital, socket fusion is used. Socket fusion involves heating the outside of a pipe while simultaneously heating the end of a socket. Once each piece is heated to the ideal temperature, the socket is then inserted into the pipe. As the two pieces cool, the connection is sealed, and flexibility remains.

Saddle Fusion

Saddle fusion connects the concave portion of a pipe to an inverse saddle fitting. To get a precise connection, both the concave portion of the pipe and the saddle fitting are heated. Once heated, the two pieces are joined together using force, and the piping is then allowed to cool under pressure. This heat/pressure method creates a tight seal at a complex connection point.

Get Expert HDPE Pipe Fusion For Any Application

Think your application may require some type of HDPE pipe fusion? US FUSION can help! Our skilled builders, contractors, and craftsmen are capable of providing valuable services across a variety of industries — helping you keep your project and environment safe.

-

DN100 PVC Pipes for Well Casings - Durable & Corrosion-Resistant

NewsAug.22,2025

-

HORON 25mm PPR Plumbing Pipes: Durable, Reliable & Leak-Proof

NewsAug.21,2025

-

32mm HDPE Pipes in Coil: Flexible & Durable Water Supply

NewsAug.19,2025

-

Flexible 32mm HDPE Pipes in Coil - Durable & Easy Install

NewsAug.18,2025

-

HDPE Sprinkler Pipe Manufacturers - Quality & Durable Solutions

NewsAug.17,2025

-

Durable DN100 PVC Well Casing Pipes for Reliable Water Supply

NewsAug.16,2025